Shaft seal device of vertical-type low-voltage non-contact reactor

A non-contact, reactor technology, applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of high machining accuracy, volatile gas escape, high power consumption, etc., and achieve low maintenance rate and convenient The effect of production, reduction of wear and corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

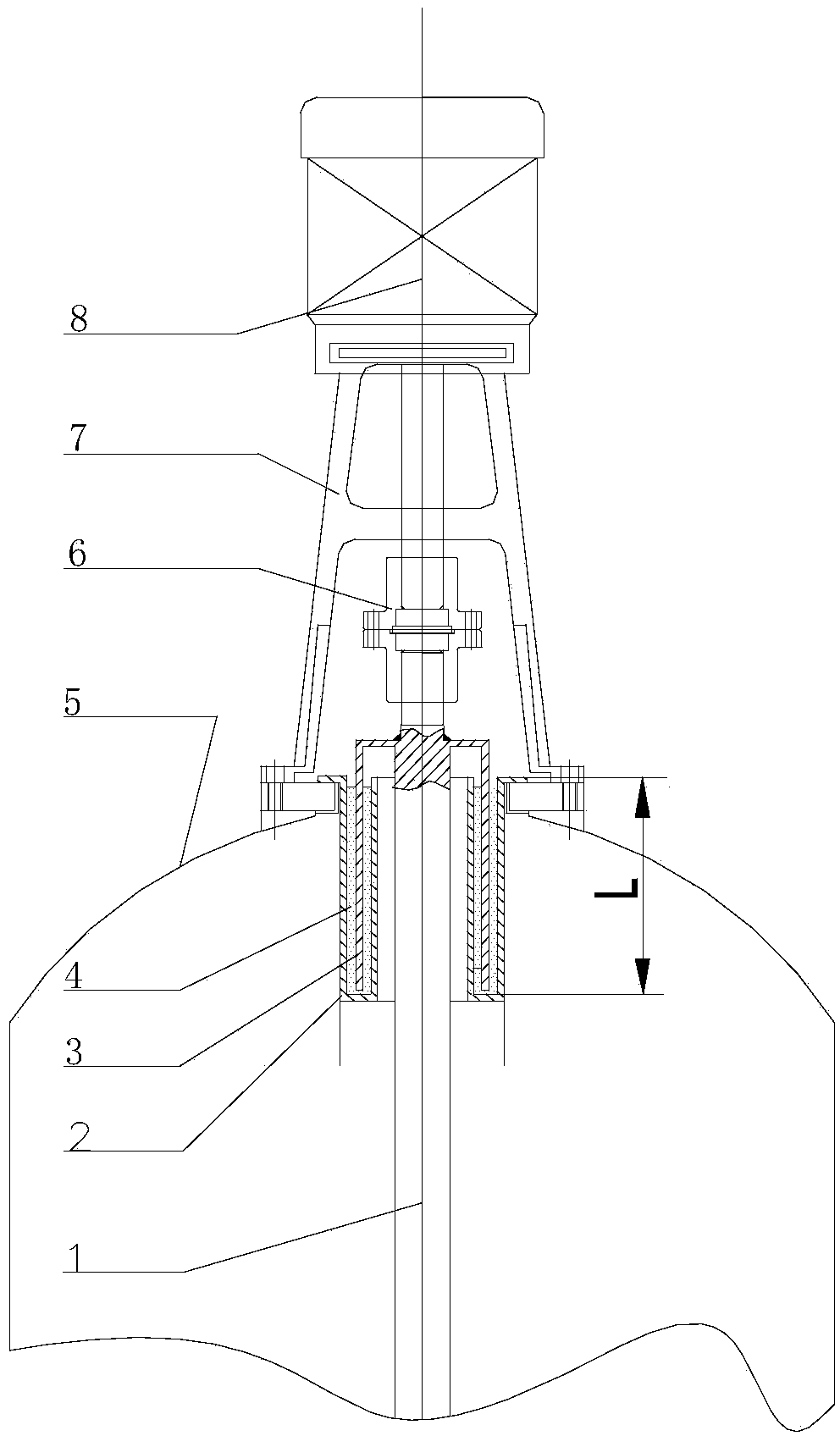

[0021] see Figure 1~3 , the embodiment of the present invention is provided with stirring shaft 1, static ring 2, moving ring 3, reactor body 5, shaft coupling 6, motor support 7, stirring motor 8; The main shaft of the motor 8 is connected, the static ring 2 is connected to the reactor body 5, the moving ring 3 is connected to the stirring shaft 1, and the sealing liquid 4 for sealing pressure is poured into the gap between the static ring 2 and the moving ring 3, The motor support 7 is located at the bottom of the stirring motor 8 .

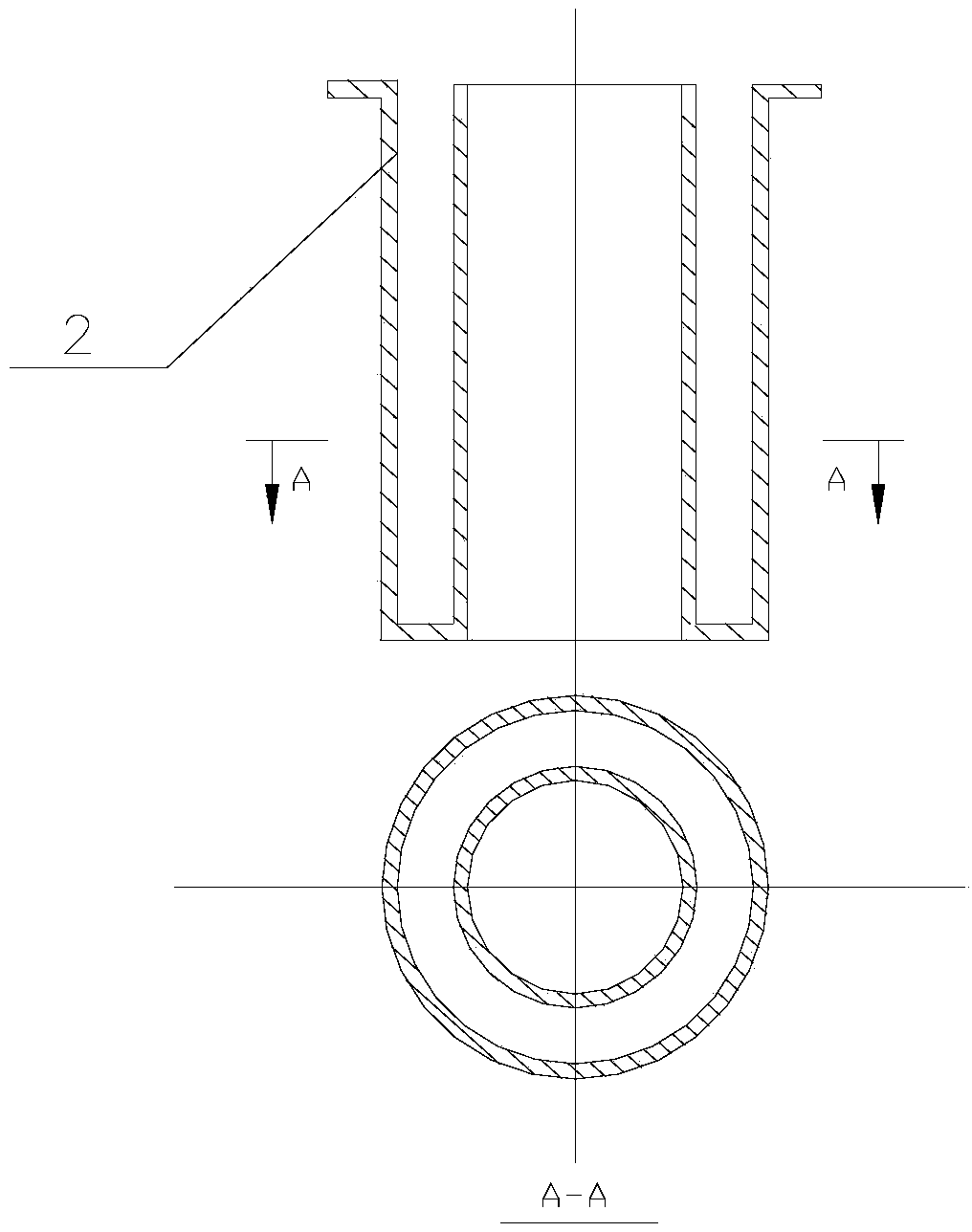

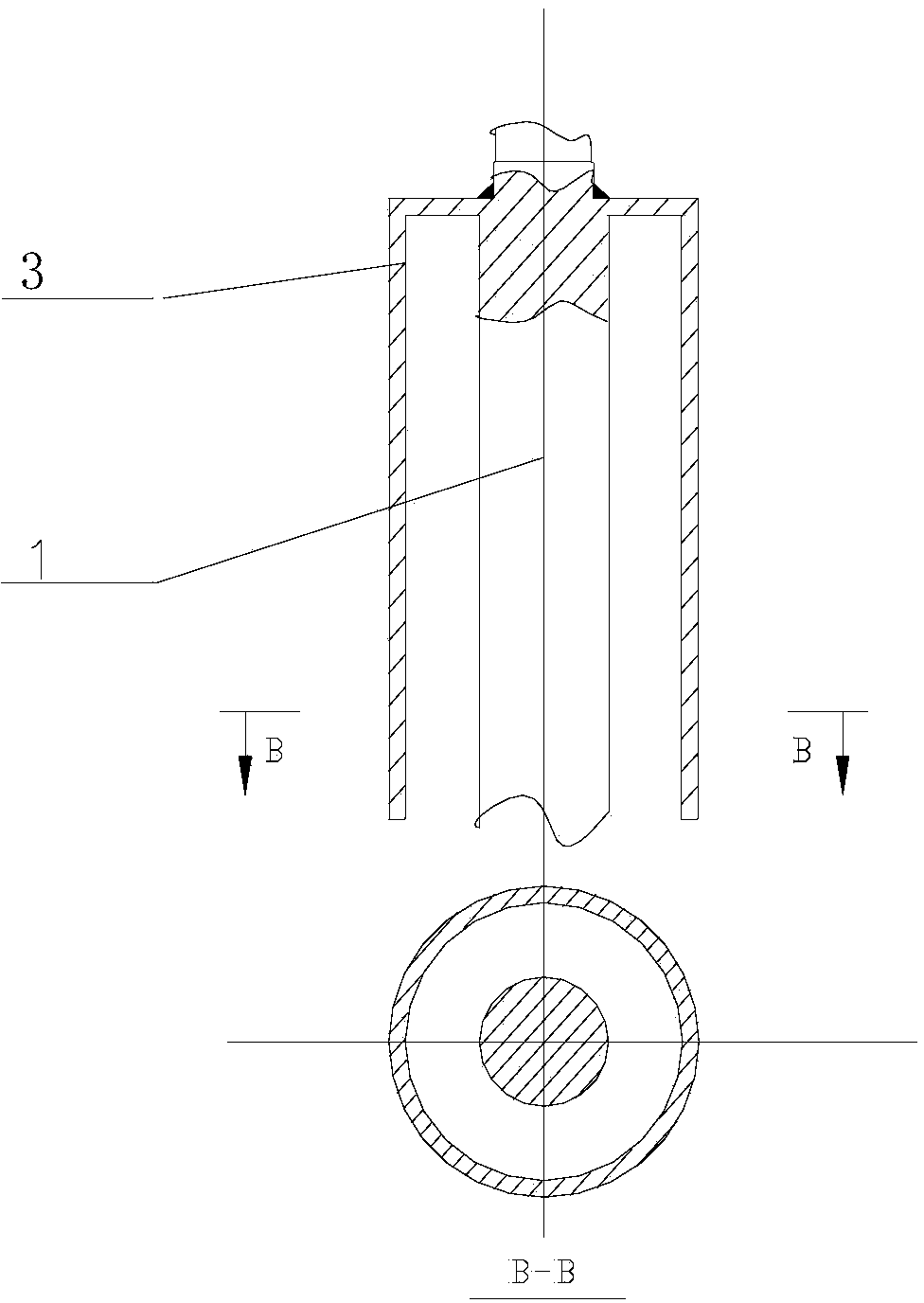

[0022] The width of the gap between the stationary ring 2 and the moving ring 3 (denoted as annular gap) may be 15-20 mm. exist figure 1 In , the mark L is the height of the static ring 2 (that is, the depth of the dynamic and static pair).

[0023] The static ring 2 is a concave groove sealing ring, and the moving ring 3 is a convex tenon sealing ring. The static ring 2 and the moving ring 3 are composed of a concave groove and a convex te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com