High-pressure high-temperature liquid viscosity measuring device and method

A high-temperature, high-pressure, and liquid-viscosity technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as increased system resistance, instability, and changes in the rheological properties of oil-coal slurry, so as to improve the sealing performance of the system and ensure uniformity , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

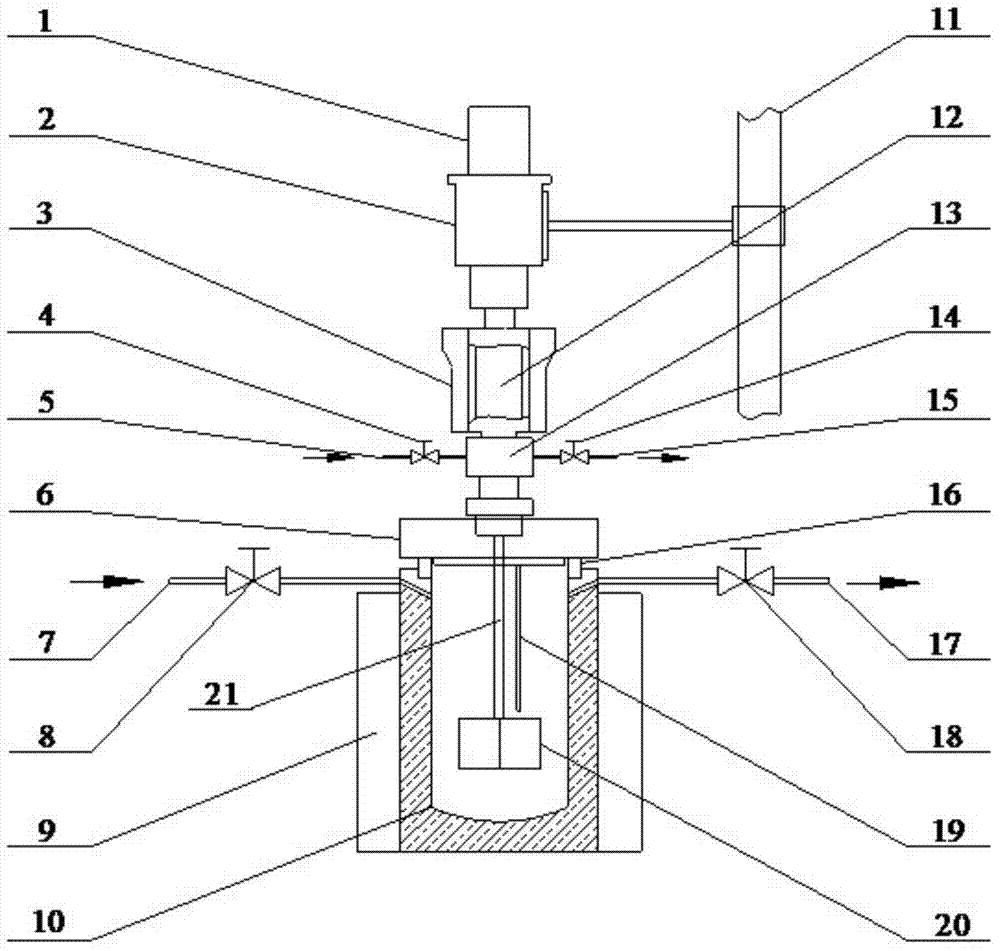

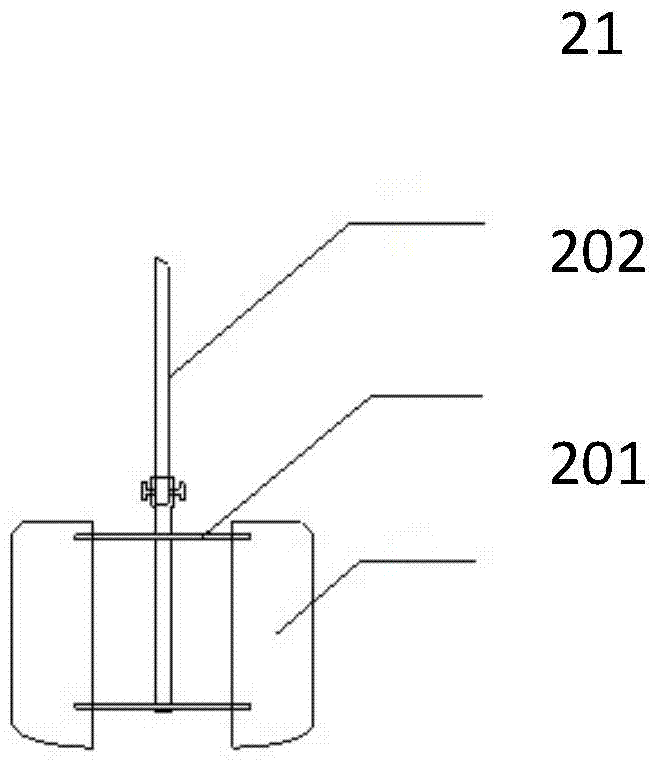

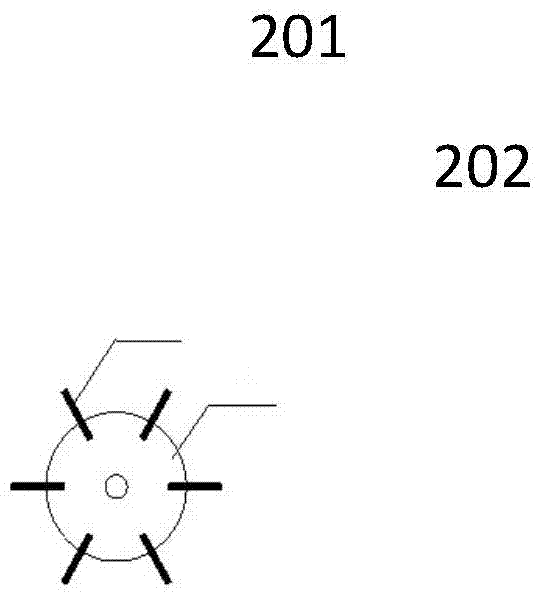

[0036] Such as figure 1 As shown, an embodiment of the present invention proposes a high-temperature and high-pressure liquid viscosity measurement device, which includes a high-temperature and high-pressure system and a measurement system. The high-temperature and high-pressure system is used to accommodate liquids and provide high-temperature and high-pressure environments for liquids, which can be A closed high-temperature and high-pressure reactor with a function of heating and pressurizing; the measurement system includes a drive motor 1, a torque sensor 2, a drive magnetic cylinder 3, an induction magnetic cylinder 12, a rotating shaft 21 and a stirring paddle 20; the drive motor 1 and The upper end of the torque sensor 2 is connected to provide driving force for the torque sensor 2, so that it drives the assembly connected to its lower end to rotate. In the embodiment of the present invention, a portable micro-motor is selected; the lower end of the torque sensor 2 It i...

Embodiment 2

[0047] An embodiment of the present invention provides a method for measuring the viscosity of a high-temperature and high-pressure liquid. The measuring method uses the high-temperature and high-pressure liquid viscosity measuring device provided in the above-mentioned embodiment for measurement. The measuring method includes the following steps:

[0048] Step 1: adding liquid into the high temperature and high pressure system, making it submerge the stirring paddle 20;

[0049] The liquid described in the embodiment of the present invention is oil-coal slurry, and the oil-coal slurry is formed by coal powder with a particle size of less than 74 μm, a hydrogen-donating solvent and a catalyst according to a certain ratio. In other embodiments, the liquid can also be Other liquids that need to measure rheological properties in petroleum, chemical and other fields. The high-temperature and high-pressure system described in this embodiment includes a miniature high-pressure react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com