DC-DC conversion circuit suitable for power supply on high-voltage side of IGBT drive module

A technology of DC-DC and drive modules, applied in the direction of adjusting electrical variables, output power conversion devices, DC power input conversion to DC power output, etc., can solve IGBT signal transmission and processing unit interference, and is not suitable for installing IGBT drive modules , IGBT drive module application limitations and other issues, to achieve high power transfer efficiency, alleviate heating problems, and improve transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

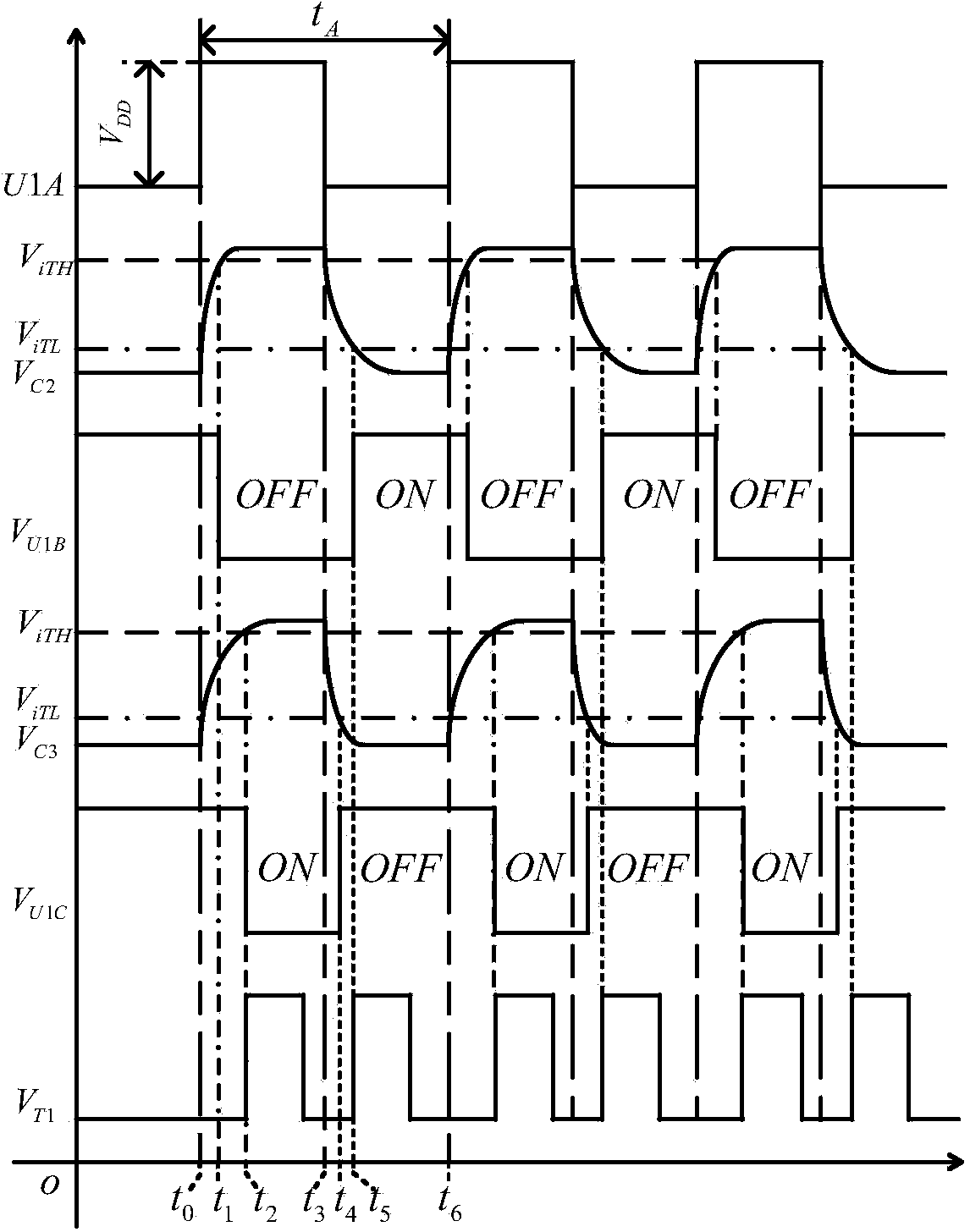

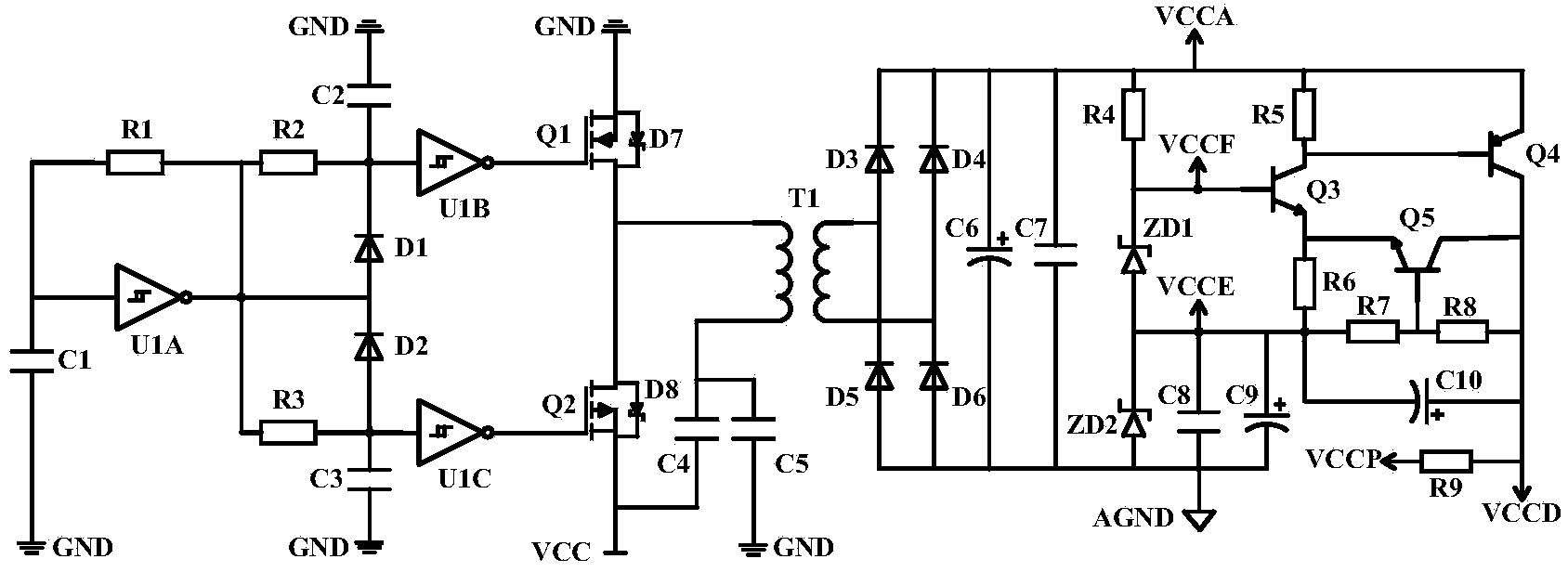

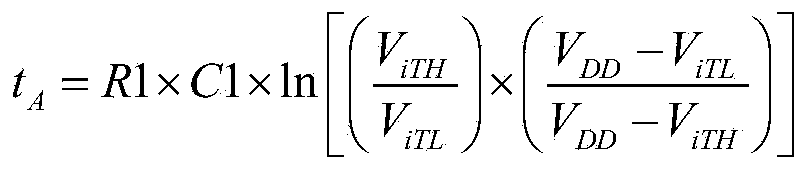

[0018] combine figure 1 and figure 2 , in order to improve the power transmission efficiency of the DC-DC conversion circuit of the present invention, the oscillation frequency of the astable multivibrator is adjusted to 0.5MHz, the power supply voltage VCC is 15V, and the output voltage VCCD is used to provide a forward guide when the IGBT module is turned on On-voltage, the reference voltage VCCE is connected to the emitter of the IGBT module, which is used to provide a reverse turn-off voltage when the IGBT module is turned off. The value of the output voltage VCCD relative to the reference voltage VCCE is 15V, and the voltage regulation value of the voltage regulator ZD1 is 10V, the regulator value of Zener tube ZD2 is 8V, figure 1 U1A in is the waveform diagram of the output terminal of the first Schmitt inverting flip-flop U1A, V C2 is the waveform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com