Method for rapidly curing meats through electrification

A meat and fast technology, applied in food preparation, preservation of meat/fish with liquid, preservation of meat/fish with chemicals, etc., can solve the problems of expensive equipment investment, affecting product appearance, affecting promotion, etc. Full-bodied, bright-colored effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] 1) Remove the subcutaneous fat, connective tissue and other impurities attached to the surface of the fresh duck breast, clean it and divide it into 8×4cm rectangular meat pieces, each piece of meat is about 50g.

[0016] 2) Put the meat into the marinating barrel, the volume ratio of the meat to the marinating liquid is 1:2.5. The pickling liquid is prepared by boiling and cooling 8% NaCl, 2% sugar, 1% monosodium glutamate, appropriate amount of onion ginger and spices according to mass percentage.

[0017] 3) Install the graphite electrode on the edge of the marinating barrel, connect the AC power supply to the graphite electrode, adjust the marinating circuit current to 0.8A±0.2A, control the ambient temperature of the marinating workshop below 10℃, and take out the drain after marinating for 5 hours. Dry and finish marinating.

example 2

[0019] 1) After removing the scales and internal organs of the fresh grass carp, wash it with clean water and divide the grass carp into pieces of 3cm thick.

[0020] 2) Put the fish pieces in the marinating barrel, the volume ratio of the fish pieces to the marinating liquid is 1:2. The pickling liquid is prepared by boiling and cooling with 10% NaCl, 2% sugar, 1% MSG, appropriate amount of green onion and ginger and spices according to mass percentage.

[0021] 3) Install the graphite electrode on the edge of the pickling barrel, connect the AC power supply to the graphite electrode, adjust the pickling circuit current to 1A±0.2A, control the ambient temperature of the pickling workshop to below 10°C, take it out and drain after pickling for 4h , Finish marinating.

example 3

[0023] 1) Remove the hair and other debris attached to the surface of the fresh pork, wash it with clean water, and divide the pork into 5cm thick pieces.

[0024] 2) Put the meat pieces in the marinating barrel, the volume ratio of the meat pieces to the marinating liquid is 1:2.5. The pickling liquid is prepared by boiling and cooling by 6% NaCl, 2% sugar, 1% MSG, appropriate amount of green onion and ginger and spices.

[0025] 3) Install the graphite electrode on the edge of the pickling barrel, connect the AC power supply to the graphite electrode, adjust the pickling circuit current to 1.3A±0.2A, and control the ambient temperature of the pickling workshop to be below 10℃. After pickling for 4 hours, remove the drain Dry and finish marinating.

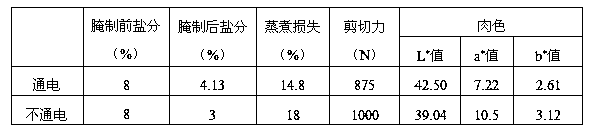

[0026] The above three examples illustrate: the method of the present invention not only speeds up the pickling speed, shortens the pickling time, and reduces the production cost; moreover, the quality of the cured meat is improved, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com