Deoxidization preservative suitable for low-humidity environment and preparation method thereof

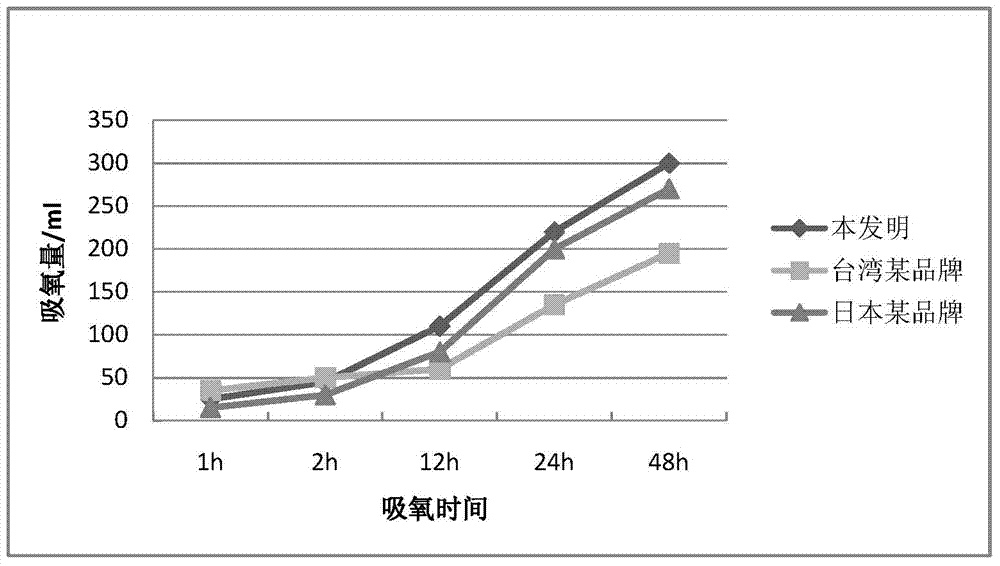

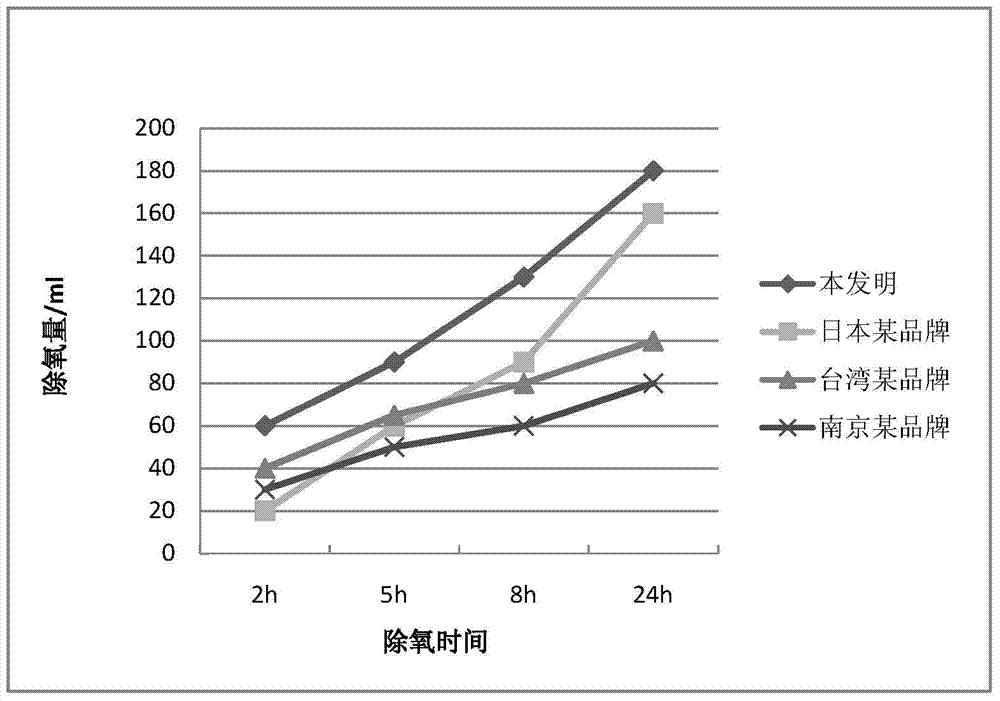

A deoxidizing preservative and low-humidity technology, applied in the field of deoxidizing preservative and its preparation, can solve the problems of soft packaging film, incomplete oxygen absorption, delamination, etc., achieve complete oxygen absorption and solve the problem of greatly improved oxygen absorption capacity Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

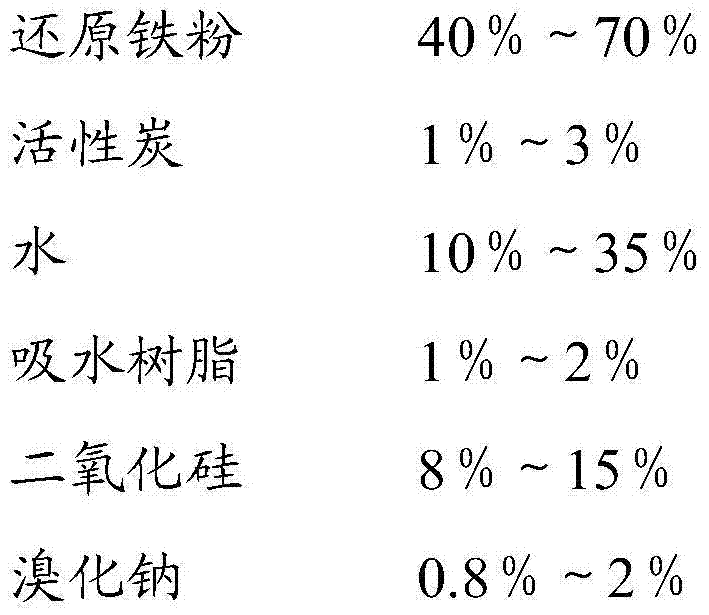

Embodiment 1

[0034] A deoxidizing preservative suitable for low-humidity environments, comprising 40% of reduced iron powder, 1% of activated carbon, 35% of water, 2% of water-absorbing resin, 15% of silicon dioxide, 2% of sodium bromide, oxidized Calcium 5%.

[0035] The method for preparing the deoxidizing preservative comprises the following preparation steps:

[0036] Step A, the sodium bromide of described amount is dissolved in water, obtains sodium bromide aqueous solution;

[0037] Step B. Mix the amount of reduced iron powder with the water-absorbing resin for 1 to 2 minutes, then add half the amount of sodium bromide aqueous solution at a stirring speed of 40 to 60 rpm and stir evenly for 4 to 8 minutes to obtain a mixture Material Ⅰ;

[0038] Step C. Mix silicon dioxide into the other half of the sodium bromide aqueous solution, mix well and add activated carbon and calcium oxide respectively to obtain the mixed material II;

[0039] Step D, mixed material I and mixed materia...

Embodiment 2

[0042] A deoxidizing preservative suitable for low-humidity environments, comprising 70% of reduced iron powder, 3% of activated carbon, 11% of water, 1% of water-absorbing resin, 8% of silicon dioxide, 2% of sodium bromide, oxidized Calcium 5%.

[0043] The method for preparing the deoxygenation preservative is the same as in Example 1.

Embodiment 3

[0045] A deoxidizing preservative suitable for low-humidity environments, comprising 54% of reduced iron powder, 2.2% of activated carbon, 30% of water, 1.5% of water-absorbing resin, 9.5% of silicon dioxide, 0.8% of sodium bromide, oxidized Calcium 2%.

[0046] The method for preparing the deoxygenation preservative is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com