Preparation method of rare earth complex crystal boundary modification sintered neodymium-iron-boron magnetic body

A rare earth complex and grain boundary modification technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of deterioration of magnetic properties of magnets and easy oxidation, so as to improve magnetic properties and increase rare earth content , the effect of reducing oxygen uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

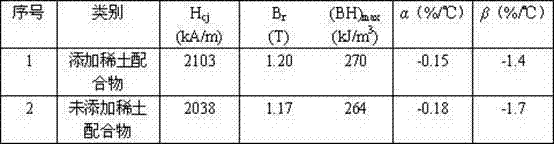

Embodiment 1

[0022] Preparation of brand 33UH NdFeB magnets by sintering method

[0023] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting process, and then the NdFeB quick-setting sheet is broken into 1-10 micron NdFeB alloy particles by hydrogen explosion method;

[0024] 2) Powder making: While further crushing the NdFeB alloy particles treated by the hydrogen explosion process to make powder, inject the mixture of borate and polyethylene oxide monofatty acid ester in a pouring manner, borate and poly The volume ratio of ethylene oxide monofatty acid ester is 1:1, and the mixture of boric acid ester and polyethylene oxide monofatty acid ester accounts for 0.01% of the total weight of NdFeB powder;

[0025] 3) Mixing: The rare earth lanthanide porous polymer [(Pr, Nd) 2 (PDA) 3 (H 2 O)]·2H 2 The mixed liquid of 0 and gasoline is injected into the NdFeB powder, and the rare earth lanthanide porous polymer [(Pr, Nd) 2 (PDA) 3 (H 2 O)]·2H ...

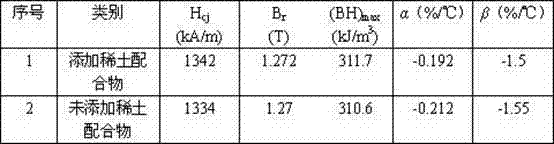

Embodiment 2

[0035] Preparation of brand 40SH-P NdFeB magnets by sintering method

[0036] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting process, and then the NdFeB quick-setting sheet is broken into 1-10 micron NdFeB alloy particles by hydrogen explosion method;

[0037] 2) Powder making: While further crushing the NdFeB alloy particles treated by the hydrogen explosion process to make powder, inject the mixture of borate and polyethylene oxide monofatty acid ester in a pouring manner, borate and poly The volume ratio of ethylene oxide monofatty acid ester is 1:1.2, and the mixture of borate ester and polyethylene oxide monofatty acid ester accounts for 0.5% of the total weight of NdFeB powder;

[0038] 3) Mixing: The rare earth lanthanide porous polymer [(Pr, Nd) 2 (PDA) 3 (H 2 O)]·2H 2 The mixed liquid of 0 and gasoline is injected into the NdFeB powder, and the rare earth lanthanide porous polymer [(Pr, Nd) 2 (PDA) 3 (H 2 O)]·2H 2...

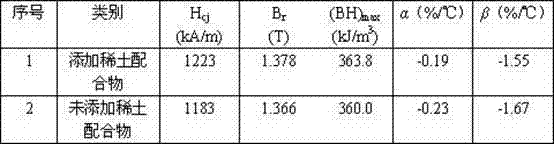

Embodiment 3

[0048] Preparation of brand 38M NdFeB magnets by sintering method

[0049] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting process, and then the NdFeB quick-setting sheet is broken into 1-10 micron NdFeB alloy particles by hydrogen explosion method;

[0050] 2) Powder making: While further crushing the NdFeB alloy particles treated by the hydrogen explosion process to make powder, inject the mixture of borate and polyethylene oxide allyl ether in a pouring manner, borate and The volume ratio of polyethylene oxide allyl ether is 1:2, and the mixture of borate ester and polyethylene oxide allyl ether accounts for 0.8% of the total weight of NdFeB powder;

[0051] 3) Mixing: [Tb(2,5-pdc)(OH)(H 2 O) 2 ]·H 2 O and DyCl 3 The rare earth mixture and gasoline are mixed and injected into the NdFeB powder, [Tb(2,5-pdc)(OH)(H 2 O) 2 ]·H 2 O accounts for 1.5% of the total NdFeB powder, DyCl 3 It accounts for 1% of the total amount of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com