Method for preparing curcumin lipid nano-particle suspension or nano-particles

A curcumin lipid and nanoparticle technology, which is applied in the direction of making medicines into special physical or taking form devices, liquid delivery, emulsion delivery, etc. operation and other problems, to achieve the effect of high uniformity, high drug encapsulation rate, and prevention of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of curcumin lipid nanoparticle suspension or nanoparticle, the method comprises the following steps:

[0028] A, adding 1 weight part of curcumin and 5 to 20 weight parts of amphoteric degradable polymers into organic solvents for dissolution to form a lipid phase solution;

[0029] B. Add 5-20 parts by weight of surfactant into water to dissolve to form an aqueous phase solution;

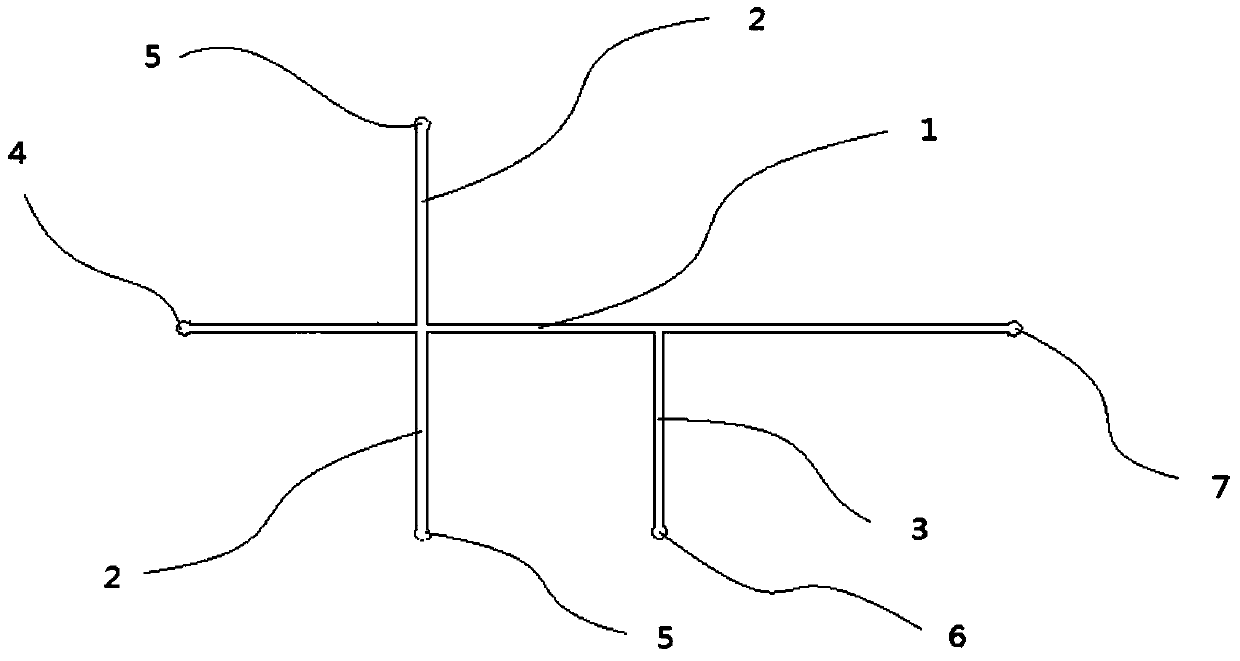

[0030] C. Then inject the lipid phase solution and the water phase solution into the microchannel of the channel reactor so that the lipid phase solution and the water phase solution are mixed into granules in the microchannel reactor, and the flow rate of the water phase is controlled to be 0.65 ~ 0.75mL / min The flow rate of the lipid phase is 0.2-0.5mL / min, and then the organic solvent is removed to obtain the curcumin lipid nanoparticle suspension.

[0031] Preferably, the flow rate of the aqueous phase is 0.68-0.7 mL / min; the flow rate of the lipid phase is ...

Embodiment 1

[0035] Precisely weigh 0.75 mg of curcumin and 10 mg of PLGA and dissolve them in 10 mL of acetone solvent to prepare a lipid phase solution for subsequent use;

[0036] At the same time, weigh 10 mg of poloxamer (P-188) and dissolve it in ultrapure water to prepare an aqueous phase solution for later use;

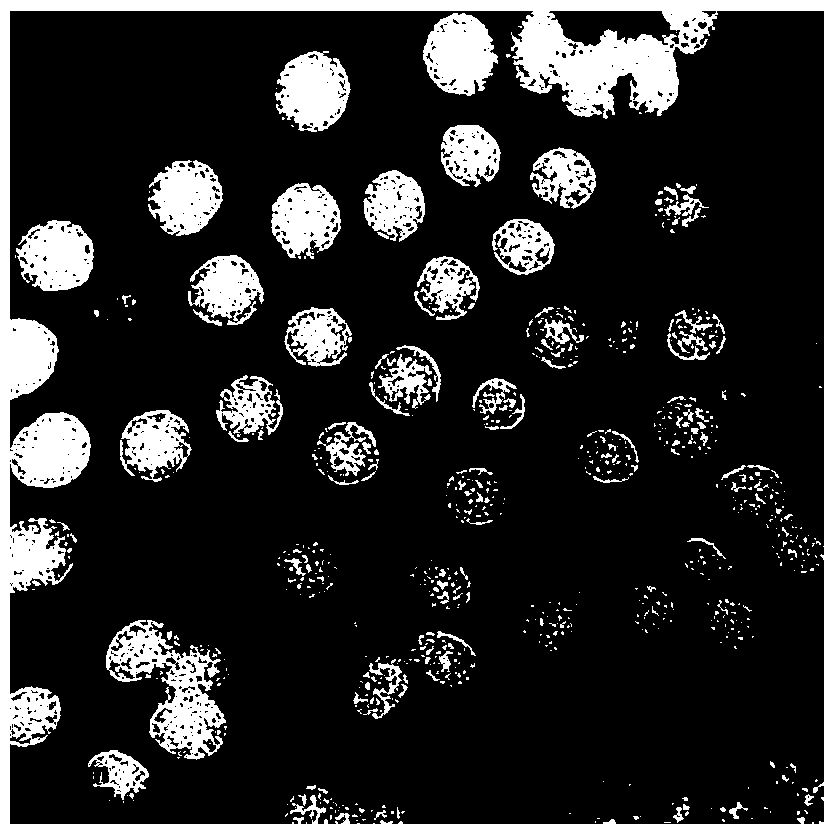

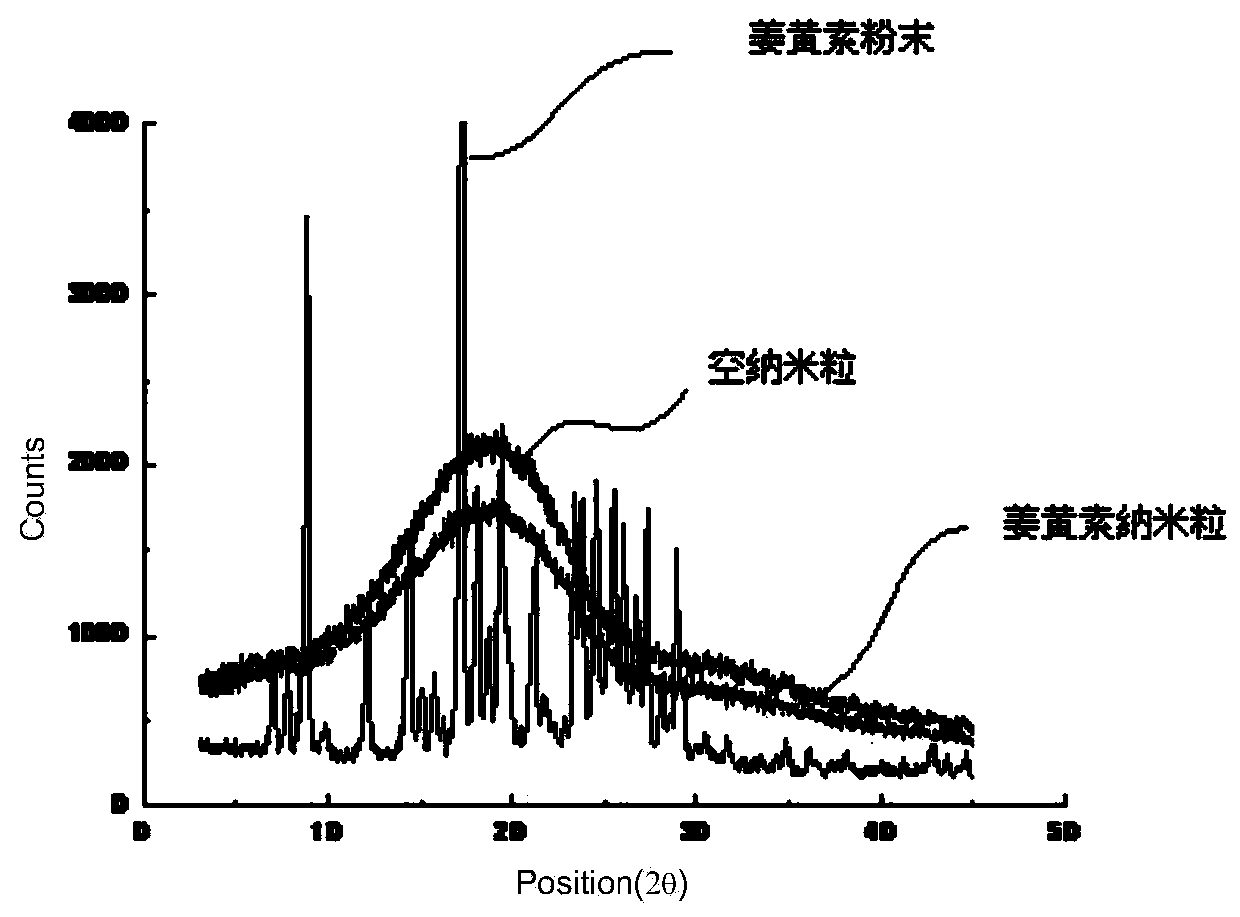

[0037] Then inject the lipid phase solution and the aqueous phase solution into the microchannel of the microchannel reactor to make the lipid phase solution and the aqueous phase solution mix and granulate in the microchannel reactor, and control the flow rate of the aqueous phase to be 0.65mL / min; The flow rate is 0.5mL / min, collects effluent, removes organic solvent again, obtains curcumin lipid nanoparticle suspension. According to the corresponding detection, the average encapsulation efficiency of the curcumin lipid nanoparticle suspension was 94.92±0.28%, the average particle size was 107.5±1.18nm, the Zeta potential was -25.30mV, and the drug loading was 1.02%.

Embodiment 2

[0039] Precisely weigh 0.75 mg of curcumin and 3.75 mg of m-PLGA and dissolve them in 10 mL of ethanol solvent to prepare a lipid phase solution for later use;

[0040] At the same time, 3.75 mg of PVA was weighed and dissolved in ultrapure water to prepare an aqueous phase solution for subsequent use;

[0041] Then inject the lipid phase solution and the aqueous phase solution obtained above into the microchannel of the microchannel reactor so that the lipid phase solution and the aqueous phase solution are mixed and granulated in the microchannel reactor, and the flow rate of the water phase is controlled to be 0.75mL / min The flow rate of the lipid phase is 0.4mL / min, the effluent is collected, and the organic solvent is removed to obtain a curcumin lipid nanoparticle suspension. According to the corresponding detection, the average encapsulation efficiency of the curcumin lipid nanoparticle suspension was 91.22±0.52%, the average particle size was 105.9±1.68nm, the Zeta pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com