Preparation method for attapulgite clay-based cycloaddition reaction catalyst

A technology of attapulgite clay and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. It can solve problems such as equipment corrosion, environmental pollution, and separation of difficult products, and achieve low production costs. Reduce environmental pollution and save solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

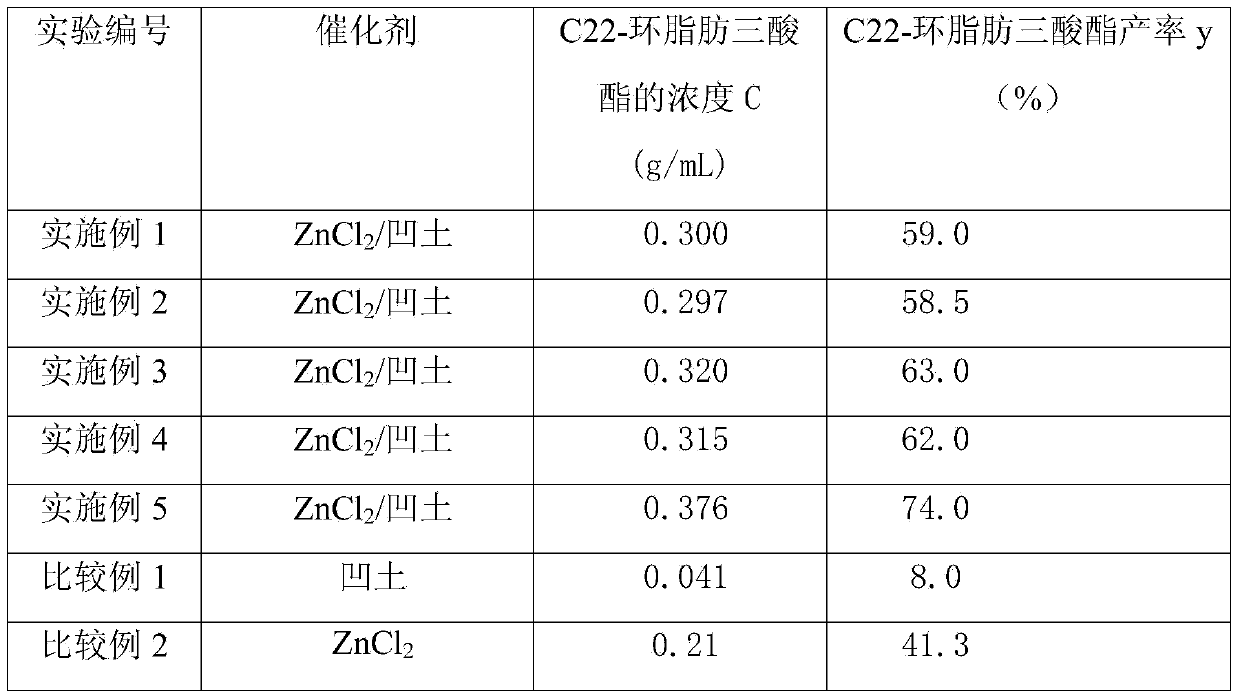

Embodiment 1

[0022] 1. Weigh 100 grams of attapulgite after drying and 5 grams of anhydrous zinc chloride respectively, mix them and add them to the ball mill tank of the ball mill, open the ball mill, and after running for 0.5 hours, collect the powder after ball milling,

[0023] The planetary ball mill QM-1SP2 is used here, and the ball milling is carried out under the protection of argon atmosphere and anhydrous and oxygen-free conditions. When the amount of zinc mixture is large, the ball milling operation can be carried out several times);

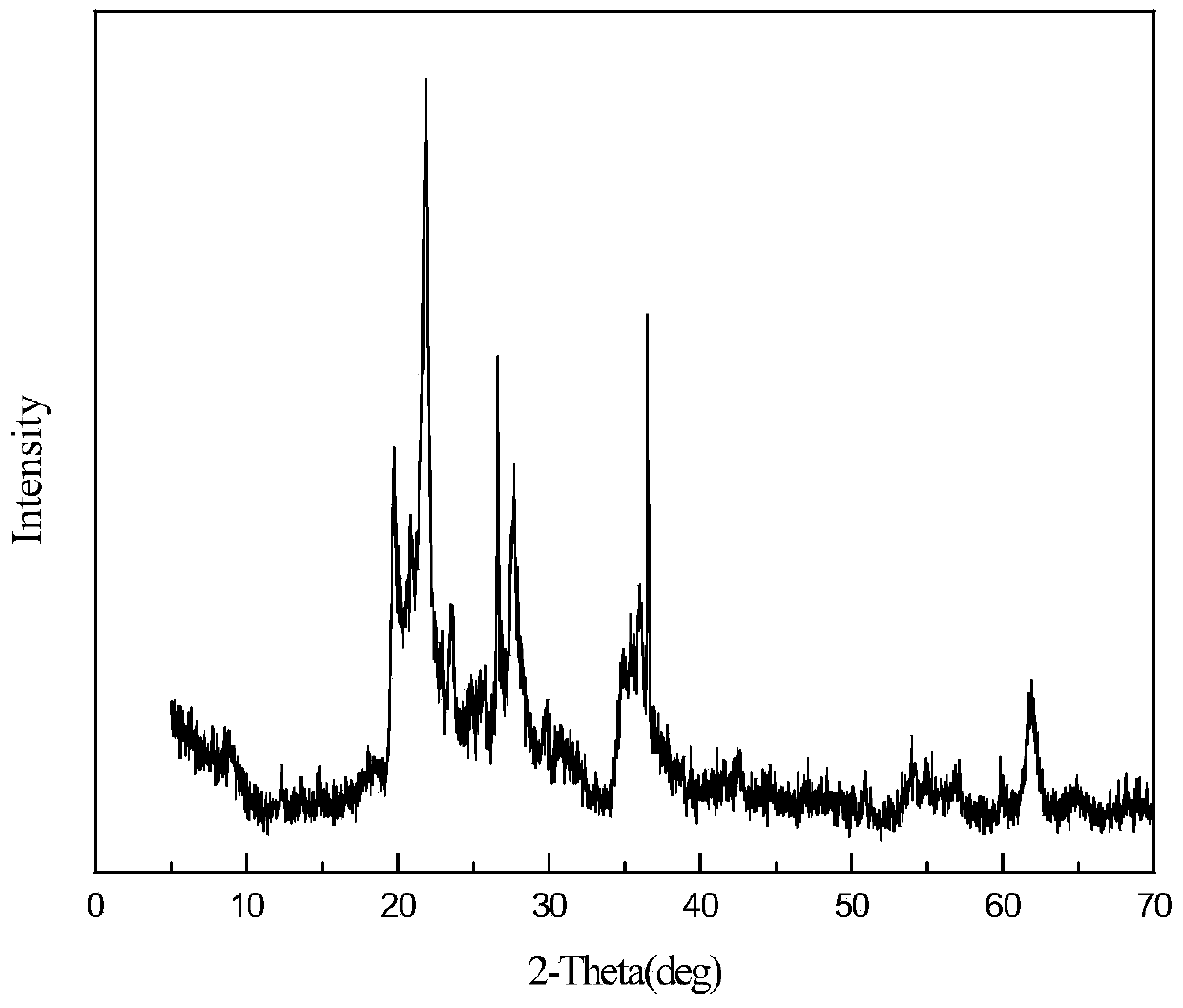

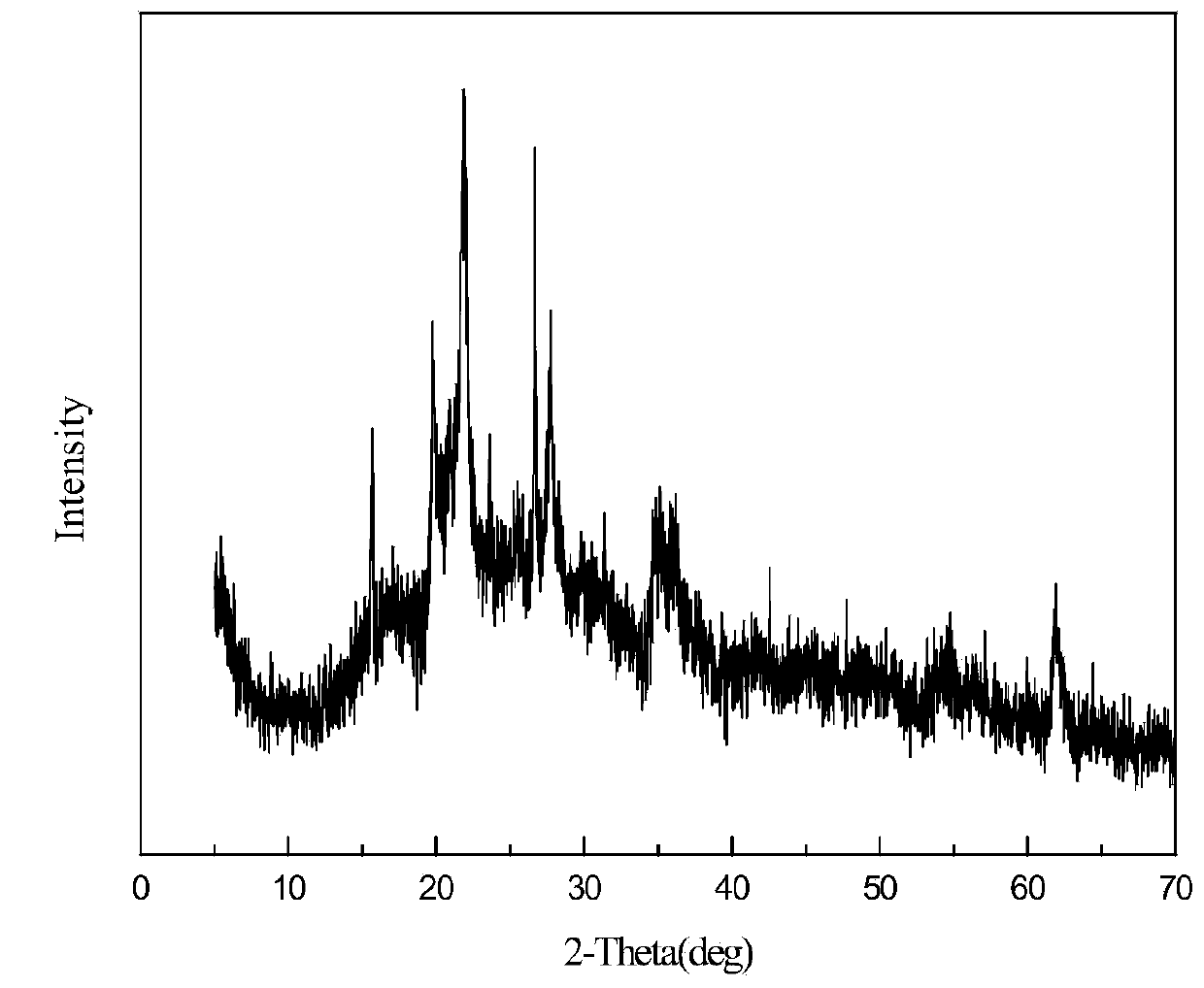

[0024] 2. Move the ball-milled powder obtained in step (1) into the roasting furnace, 2 Under the atmosphere, the temperature is raised to 250°C at a rate of 3°C / min, roasted at a constant temperature for 2 hours, and cooled to obtain ZnCl 2 / Attapulgite-supported cycloaddition catalyst.

Embodiment 2

[0026] 1. Weigh 100 grams of attapulgite after drying and 20 grams of anhydrous zinc chloride respectively, mix them and add them to the ball mill tank of the ball mill, open the ball mill, and after running for 10 hours, collect the powder after ball milling,

[0027] The planetary ball mill QM-1SP2 is used here, and the ball milling is carried out under the protection of argon atmosphere and anhydrous and oxygen-free conditions. When the amount of zinc mixture is large, the ball milling operation can be carried out several times);

[0028] 2. Move the ball-milled powder obtained in step (1) into the roasting furnace, 2 Under the atmosphere, the temperature was raised to 250°C at a rate of 8°C / min, roasted at a constant temperature for 8 hours, and cooled to obtain ZnCl 2 / Attapulgite-supported cycloaddition catalyst.

Embodiment 3

[0030] 1. Weigh 100 grams of attapulgite after drying and 15 grams of anhydrous zinc chloride respectively, mix them and add them to the ball mill tank of the ball mill, open the ball mill, and after running for 6 hours, collect the powder after ball milling,

[0031] The planetary ball mill QM-1SP2 is used here, and the ball mill is carried out under the protection of argon atmosphere and anhydrous and oxygen-free conditions. When the amount of zinc mixture is large, the ball milling operation can be carried out several times);

[0032] 2. Move the ball-milled powder obtained in step (1) into the roasting furnace, 2 Under the atmosphere, the temperature is raised to 250°C at a rate of 5°C / min, roasted at a constant temperature for 4 hours, and cooled to obtain ZnCl 2 / Attapulgite-supported cycloaddition catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com