Regeneration method for toluene methylation catalyst

A toluene methylation catalyst and catalyst bed technology, applied in the field of regeneration of deactivated catalysts, can solve the problems of complex equipment, cumbersome regeneration steps, poor catalyst activity recovery, etc., and achieve good technical effects and good activity recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

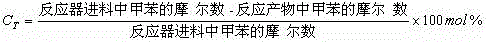

Method used

Image

Examples

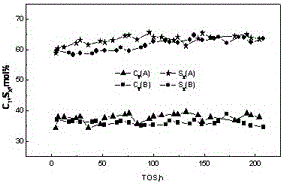

Embodiment 1

[0033] The regeneration test was carried out with the deactivated JSM-03 catalyst. The JSM-03 catalyst includes the following components in terms of weight percentage: 69.27% hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio of 280, 30.68% Al 2 o 3 , 0.05% La 2 o 3 .

[0034] The regeneration process is as follows: stop feeding the methylating reagent and toluene raw materials, and circulate hydrogen for 5 hours under the condition of constant reaction temperature and pressure; gradually release the system pressure to normal pressure, and the temperature drops below 100°C; stop introducing hydrogen , disconnect the liquid-phase feed system and product separation system to isolate the reactor system from the liquid-phase feed system and product separation system; replace the reaction system with nitrogen and purge the system with nitrogen to make the total amount of hydrogen and hydrocarbons in the system The concentration is less than 0.2% by volume; at t...

Embodiment 2

[0036] The regeneration test was carried out with the deactivated JSM-03 catalyst.

[0037] The regeneration process is as follows: stop feeding the methylating reagent and toluene raw materials, and circulate water vapor for 3 hours under the condition of constant reaction temperature and pressure; gradually release the system pressure to normal pressure, and the temperature drops below 100 ° C; stop introducing water steam, disconnect the liquid-phase feed system and product separation system, and isolate the reactor system from the liquid-phase feed system and product separation system; replace the reaction system with nitrogen, and purge the system with nitrogen, so that the hydrogen and hydrocarbons in the system The total concentration is less than 0.2% by volume; at the same time, raise the temperature of the reactor so that the temperature of the catalyst bed is 100°C, and adjust the system pressure to 1.0MPa; feed air, observe the temperature rise of the catalyst bed, ...

Embodiment 3

[0039] The regeneration test was carried out with the deactivated JSM-03 catalyst.

[0040]The regeneration process is as follows: stop feeding the methylating reagent and toluene raw materials, and circulate nitrogen for 2 hours under the condition of constant reaction temperature and pressure; gradually release the system pressure to normal pressure, and the temperature drops below 100°C; stop introducing nitrogen , disconnect the liquid-phase feed system and product separation system to isolate the reactor system from the liquid-phase feed system and product separation system; replace the reaction system with nitrogen and purge the system with nitrogen to make the total amount of hydrogen and hydrocarbons in the system The concentration is less than 0.2% by volume; at the same time, raise the temperature of the reactor so that the temperature of the catalyst bed is 250°C, and adjust the system pressure to 0.6MPa; feed air, observe the temperature rise of the catalyst bed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com