A targeted anchoring and separation agent regeneration method for sulfur in oil products

A separation agent and targeted technology, applied in separation methods, filtration separation, filter regeneration, etc., can solve the problems of industrial waste residue environmental hazards, cumbersome process, consumption, etc., to avoid incomplete regeneration, easy to industrialize, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a targeted anchoring and separation agent regeneration method for sulfur in oil, which includes the following steps:

[0030] 1. Preparation of target anchoring and separating agent

[0031] NiO / Fe 3 o 4 @SiO 2 The preparation of composite particles adopts excessive impregnation method, and its specific steps are as follows:

[0032] (1) Weigh 10.0g Fe 3 o 4 Magnetic nanoparticles were dispersed in dilute ammonia water with a concentration of 0.05M, 60.0g tetraethyl orthosilicate was added dropwise into the solution, stirred and hydrolyzed for 6 hours, and then separated to obtain Fe 3 o 4 @SiO 2 Core-shell composite particles;

[0033] (2) Weigh 0.13g nickel nitrate and dissolve it in 100ml deionized water, stir and dissolve completely to obtain 0.07M nickel nitrate solution; take 10.0g Fe 3 o 4 @SiO 2 The core-shell composite particles are placed in nickel nitrate solution and stirred for 10 hours;

[0034] (3) The mixture is subje...

Embodiment 2

[0042] With embodiment 1, just change the hydrogen air velocity into 800h -1 , to obtain the regenerated target anchoring and separating agent.

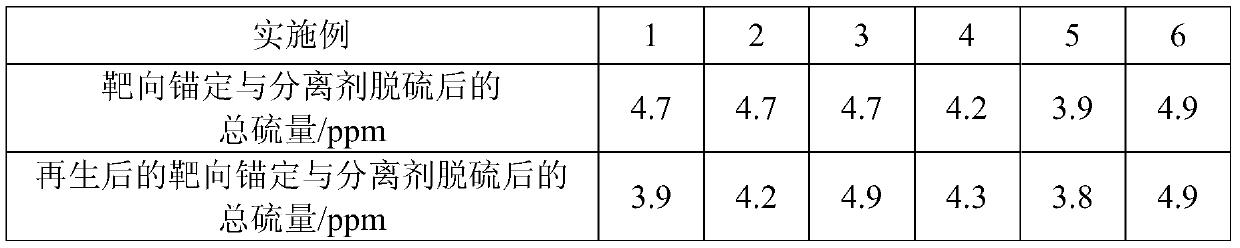

[0043] The desulfurization process of the regenerated targeting anchor and separating agent is the same as that of the targeting anchor and separating agent prepared in Example 1. The desulfurization results before and after regeneration are shown in Table 2.

Embodiment 3

[0045] With embodiment 1, just change the hydrogen air velocity into 1600h -1 , to obtain the regenerated target anchoring and separating agent.

[0046] The desulfurization process of the regenerated targeting anchor and separating agent is the same as that of the targeting anchor and separating agent prepared in Example 1. The desulfurization results before and after regeneration are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com