Modification method of Y-type molecular sieve and preparation method of catalytic cracking catalyst

A catalytic cracking and molecular sieve technology, applied in molecular sieve catalysts, catalytic cracking, physical/chemical process catalysts, etc., can solve problems such as poor effect of reducing sodium ion content, achieve good roasting effect, improve roasting quality, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a method for preparing a catalytic cracking catalyst, the method comprising: modifying a Y-type molecular sieve to obtain a modified Y-type molecular sieve, and taking the total weight of the catalytic cracking catalyst as a basis, adding 5-50% by weight of The modified Y-type molecular sieve, 0.5-50% by weight of the binder in terms of oxides and 5-90% by weight of the clay mixture are gelled, and the obtained gelled products are sequentially dried and roasted to obtain a roasted product, The roasting temperature of the dried gelled product is 350-400° C., and the roasted product is washed, filtered and dried in sequence. The washing of the roasted product is water washing, and the washing temperature of the roasted product is 20-400° C. 45°C, the weight ratio of the water used for washing the roasted product to the roasted product is 5-20:1; the method for modifying the Y-type molecular sieve is the modification of the Y-type molecul...

Embodiment 1

[0091] This example is used to illustrate the modification method of the Y-type molecular sieve of the present invention.

[0092] Add 50kg of NaY molecular sieve (Qilu Catalyst Factory) to the beating tank with 400kg of deionized water, add 150kg of ammonium sulfate, the weight ratio of water to NaY molecular sieve is 8:1, and the weight ratio of ammonium sulfate to NaY molecular sieve is 3 : 1, carry out the first exchange in the beating tank, the exchange temperature is 80 ℃, and the exchange time is 2 hours. The exchanged NaY molecular sieves enter the flash dryer for drying, the drying temperature is 180° C., and the drying time is 1.5 hours.

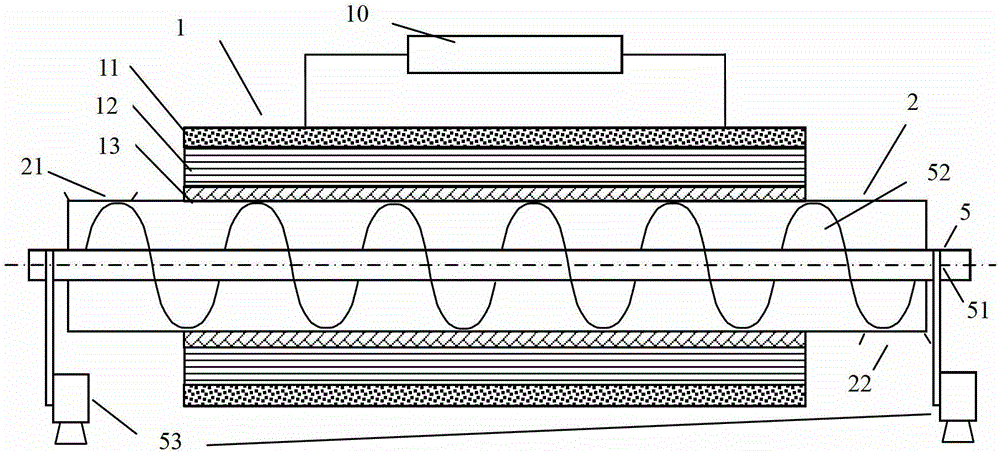

[0093] The dried NaY type molecular sieve is put into a roasting furnace as a Y type molecular sieve to be roasted for roasting. Such as figure 2 As shown, the roasting furnace is provided with an auger conveyor 5 inside the cylinder body 2 . The inner diameter of the cylinder 2 is 1 m, and the length of the cylinder 2 is 6 m. ...

Embodiment 2

[0100] This example is used to illustrate the modification method of the Y-type molecular sieve of the present invention.

[0101] Add 50kg of NaY molecular sieve (Qilu Catalyst Factory) to the beating tank with 250kg of deionized water, add 35kg of ammonium sulfate, the weight ratio of water to NaY molecular sieve is 5:1, and the weight ratio of ammonium sulfate to NaY molecular sieve is 0.7 : 1, carry out the first exchange in the beating tank, the exchange temperature is 100 ℃, and the exchange time is 1.5 hours. The exchanged NaY type molecular sieves enter the flash dryer for drying, the drying temperature is 200° C., and the drying time is 1 hour.

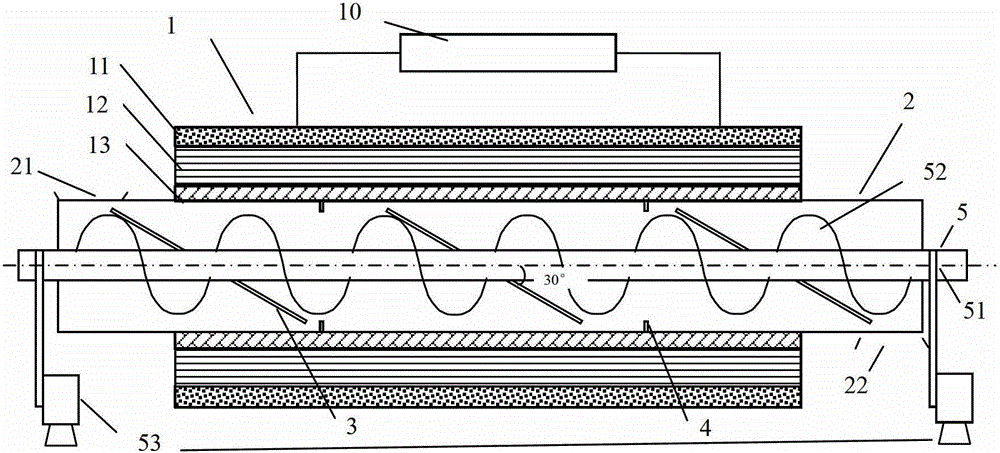

[0102] The dried NaY type molecular sieve is put into a roasting furnace as a Y type molecular sieve to be roasted for roasting. Such as image 3 As shown, different from the roasting furnace used in Example 1, the diameter of the rotating shaft 51 of the auger conveyor 5 is 20cm, the outer diameter of the helical blade 52 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com