Energy-saving slaughter wastewater treatment method

A technology for slaughter wastewater and treatment methods, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as uneven aeration, high power, and high price of aeration fans , to achieve the effect of reducing input and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

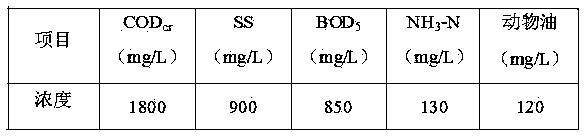

[0015] For a meat processing enterprise that slaughters 200,000 pigs in a certain year, the amount of waste water from slaughtering and processing is 300m 3 / d, raw water quality indicators are shown in Table 1.

[0016] Table 1 The wastewater quality indicators of a meat processing enterprise

[0017]

[0018] An energy-saving treatment method for slaughter wastewater, the specific steps are as follows:

[0019] (1) The waste water first flows through the all-stainless steel mechanical grille with a grid gap of 3 mm, removes pig hair, minced meat and large particle pollutants, and then flows into the sump, and then lifts it to the hydraulic rotation with the first-stage lift pump Sieve to further remove impurities such as pig hair;

[0020](2) The water from the hydraulic rotary sieve is lifted by the secondary lift pump and enters the oil-separating sedimentation adjustment comprehensive pool. In the oil-separating sedimentation area, the oil in the water is scraped by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com