Impregnating resin for high-frequency and low-frequency electronic transformers

An electronic transformer and impregnated resin technology, which is applied in coatings, polyester coatings, etc., to achieve the effects of improving mechanical strength, storage stability, and excellent secondary solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

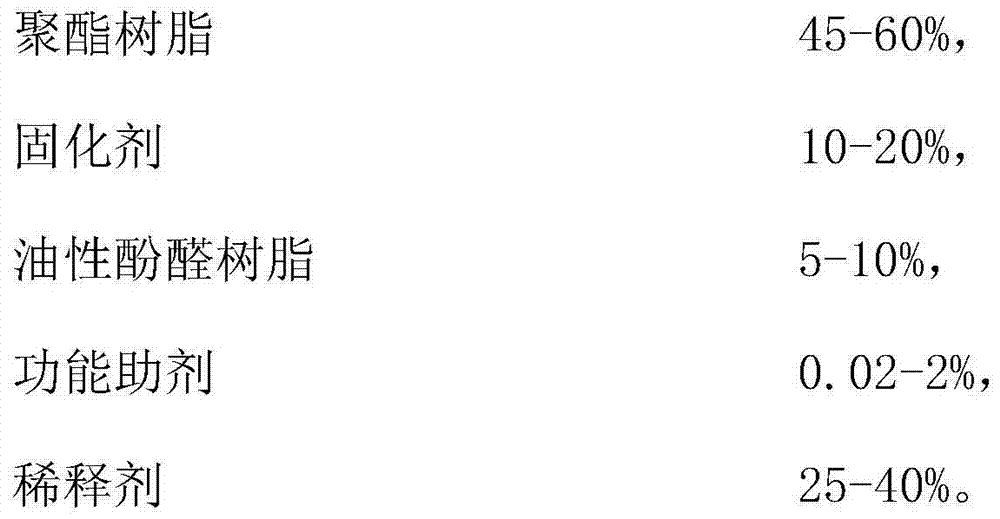

[0037] According to the formula of solvent-impregnated resin for high and low frequency electronic transformers of the present embodiment:

[0038] 45g of polyester resin, 20g of 582-2 amino resin, 6g of oily phenolic resin, 0.1g of cobalt naphthenate, 9g of 200# solvent oil, and 20g of xylene.

[0039] After the above-mentioned components are uniformly mixed according to the formula, the solvent-impregnated resin for high- and low-frequency electronic transformers is obtained. When the impregnating resin is in use, it should be cured at about 120°C for 2 hours to form a film.

Embodiment 2

[0041] According to the formula of solvent-impregnated resin for high and low frequency electronic transformers of the present embodiment:

[0042] 55g of polyester resin, 15g of 582-2 amino resin, 10g of oily phenolic resin, 1.0g of ammonium p-toluenesulfonate, 4g of 120# solvent oil, and 15g of xylene.

[0043] After the above-mentioned components are uniformly mixed according to the formula, the solvent-impregnated resin for high- and low-frequency electronic transformers is obtained. When the impregnating resin is in use, it should be cured at about 120°C for 2 hours to form a film.

Embodiment 3

[0045] According to the formula of solvent-impregnated resin for high and low frequency electronic transformers of the present embodiment:

[0046] 60g of polyester resin, 10g of 582-2 amino resin, 7g of oily phenolic resin, 0.5g of zinc isooctanoate, 13g of xylene, 10g of 1500# solvent oil.

[0047] After the above-mentioned components are uniformly mixed according to the formula, the solvent-impregnated resin for high- and low-frequency electronic transformers is obtained. When the impregnating resin is in use, it should be cured at about 120°C for 2 hours to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com