Semi-tower three-flue double-damper added jet flow flue gas recirculation secondary reheating power station boiler

A technology of flue gas recirculation and secondary reheating, which is applied in steam boilers, lighting and heating equipment, non-flammable liquid/gas transportation, etc. Consumption increase and other issues, to achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

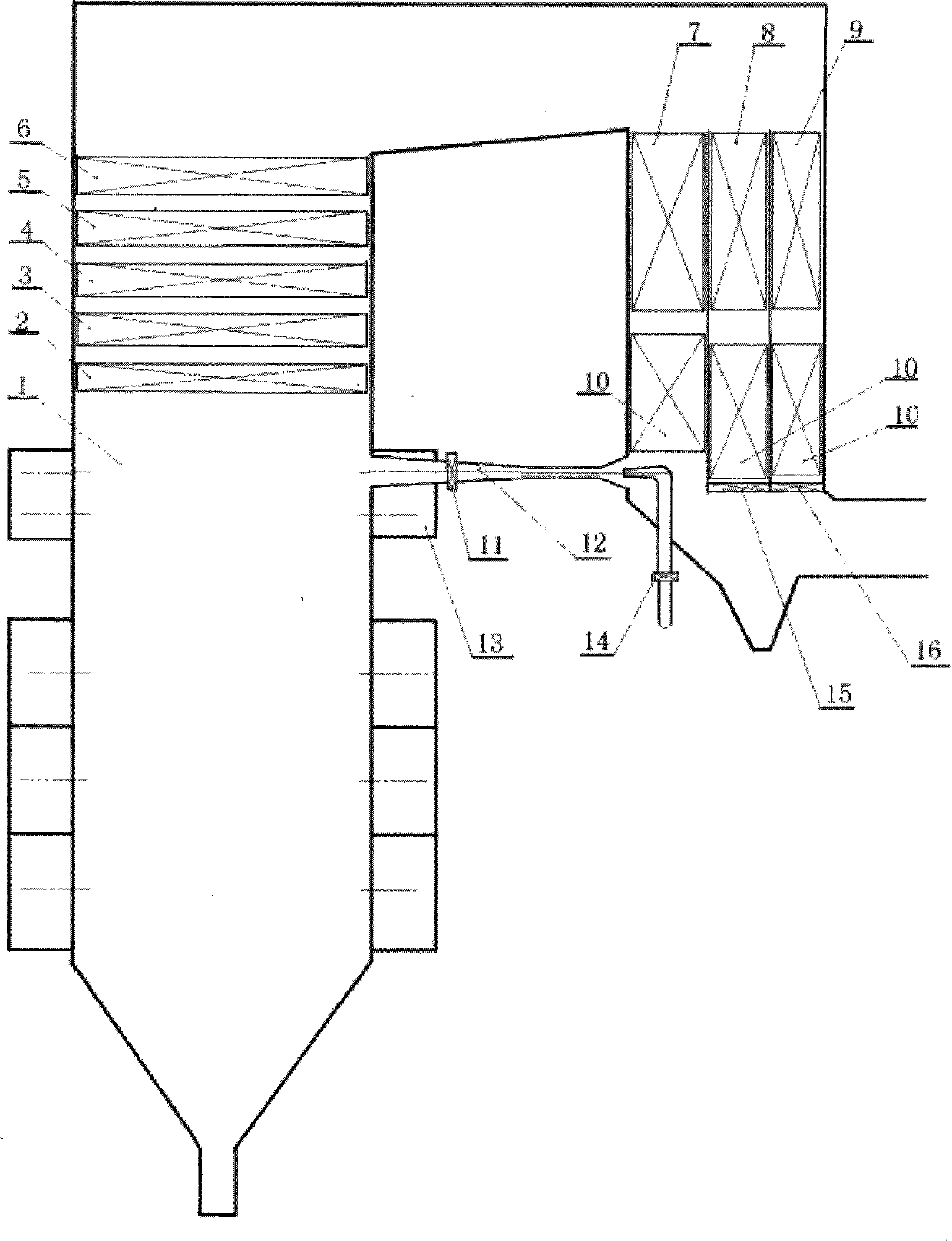

[0037] Example 1: The scheme of the two-reheat power station boiler with three flues at the tail and double baffles plus jet flue gas recirculation

[0038] Combine now figure 1 Taking a 600MW grade, main steam temperature / reheat steam temperature of 605℃ / 623℃ / 623℃ as an example to illustrate the preferred way to realize the invention.

[0039]The utility model of the present invention includes three flues at the tail, double baffles and jet flue gas recirculation, and the secondary reheating power station boiler includes a furnace and a burner (1), a screen superheater (2), a primary medium temperature reheater (3), and a high temperature superheater. (4), primary high temperature reheater (5), secondary high temperature reheater (6), secondary low temperature reheater (7) primary low temperature reheater (8), low temperature superheater (9), coal-saving (10), air-smoke ejector shut-off baffle (11), temperature-adjusted air-smoke ejector (12), separation secondary air bellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com