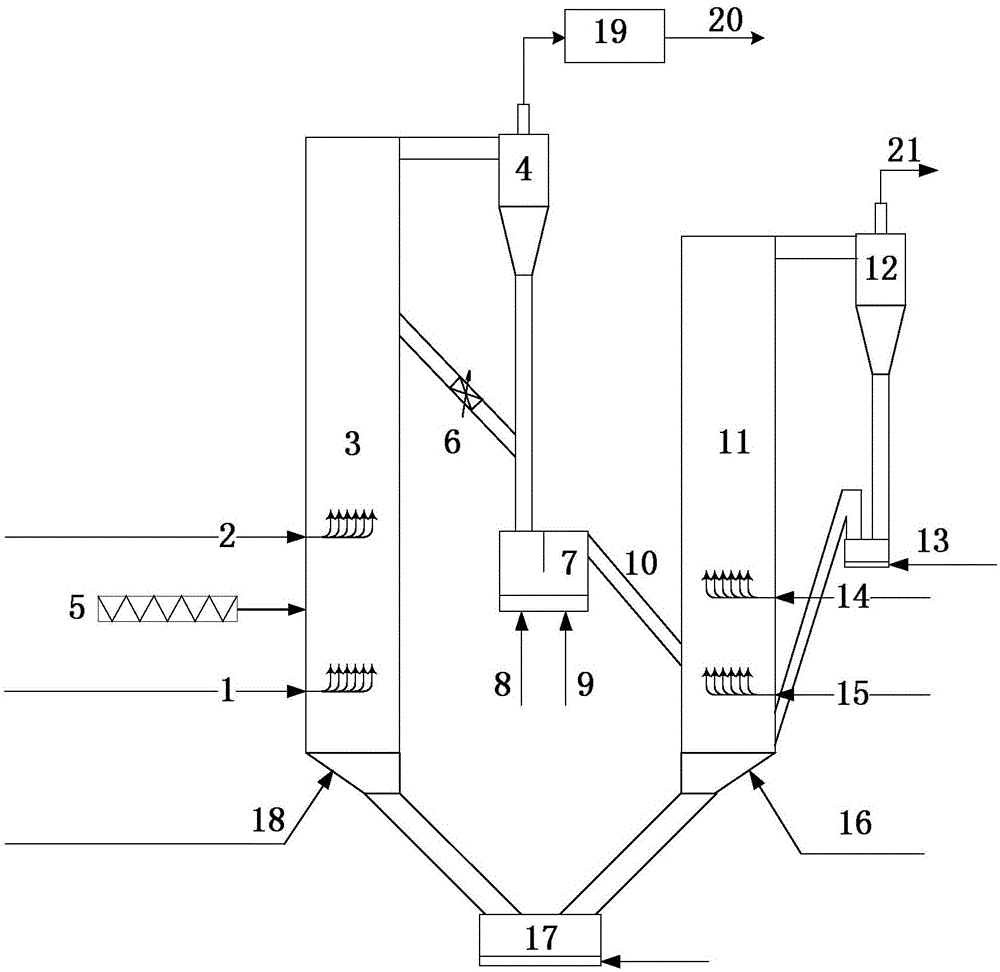

A double fluidized bed gas-solid combustion device and method

A combustion device and dual fluidized bed technology, applied in the field of dual fluidized bed gas-solid combustion devices, can solve problems such as difficulty in controlling the amount of material circulation, difficulty in adapting to changes in fuel types, etc., achieving good fuel adaptability, low transfer resistance, Efficient use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

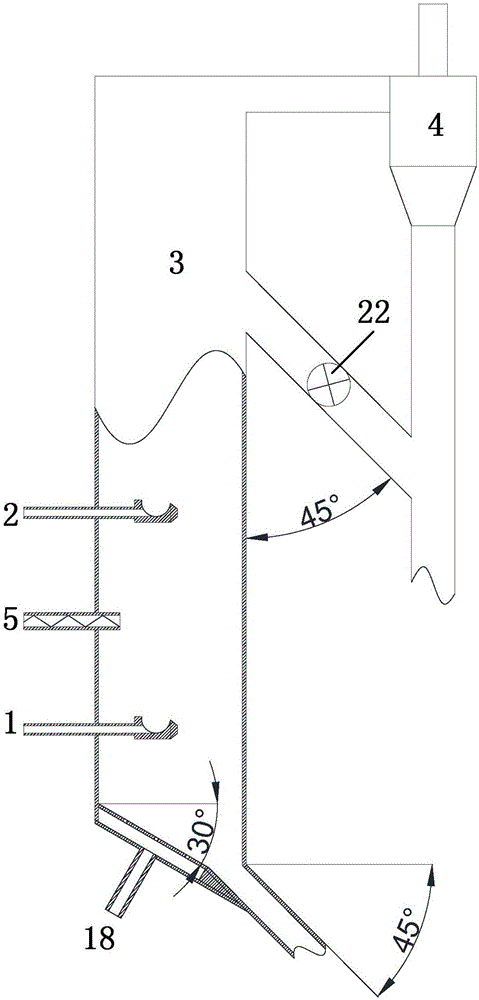

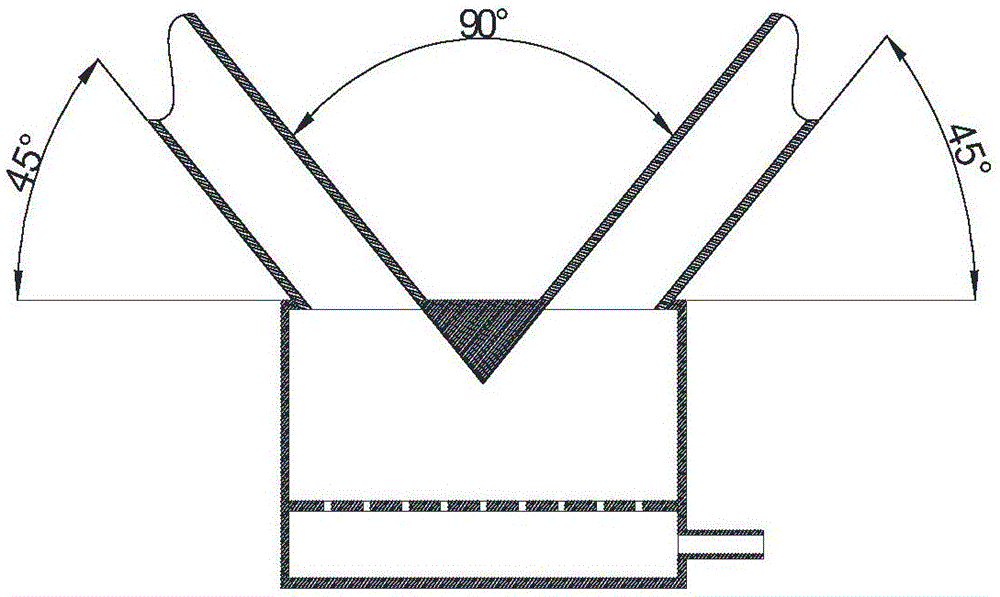

Embodiment 1

[0036] The fuel is coal and natural gas (the main component is CH4), and the circulating bed material is iron ore. The oxidation state of the oxygen carrier contained in it mainly exists in the form of Fe2O3, and the reduced state mainly exists in the form of Fe3O4, FeO and Fe. Since the reaction rate of the oxidized oxygen carrier, coal powder, and natural gas is relatively fast under the design working conditions of the reduction reactor, by closing the valve provided on the overflow device 6 of the reduction reactor to make it run as a fast fluidized bed, the reduction reaction The superficial gas velocity in the reactor is set to 3.5-4m / s, and the superficial gas velocity in the oxidation reactor is set to 4-4.5m / s. The fluidization air volume distribution of the reduction reactor is 5% to 15% of the second nozzle, 45% to 55% of the first nozzle, and 35% to 45% of the fluidization air inlet at the bottom, and the fluidization air volume of the oxidation reactor is allocated...

Embodiment 2

[0042] The same device as in Example 1 was used, the fuel was a mixture of coal and biomass, and nickel-based oxygen carrier (NiO) was selected. Since the reaction rate between the oxidized oxygen carrier (NiO) and the mixed fuel is relatively slow under the design working conditions of the reduction reactor, it can be fluidized as bubbling by opening the valve set on the overflow device 6 of the reduction reactor. bed operation, the superficial gas velocity in the reduction reactor is set to 0.4-0.6m / s, and the superficial gas velocity in the oxidation reactor is set to 4-4.5m / s. The fluidization air volume distribution of the reduction reactor is 5% to 15% of the second nozzle, 45% to 55% of the first nozzle, and 35% to 45% of the fluidization air inlet at the bottom, and the fluidization air volume distribution of the oxidation reactor is the third nozzle 15% to 25%, the fourth nozzle 35% to 45%, and the bottom fluidization air inlet 35% to 45%.

[0043] The mixed fuel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com