Movable insulation board structure capable of adjusting hearth temperature

A technology of furnace temperature and heat shielding plate, applied in the field of movable heat shielding plate structure, can solve the problems of mechanical incomplete combustion loss, combustion instability, large coal leakage, etc., to prevent low boiler thermal efficiency and solve combustion stability Problems, the effect of preventing slagging in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

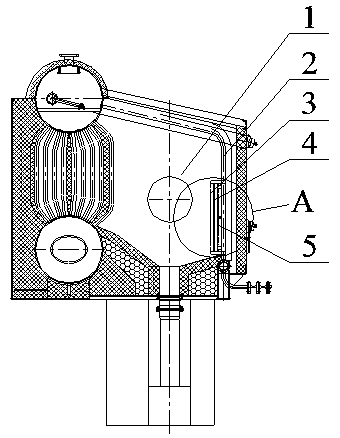

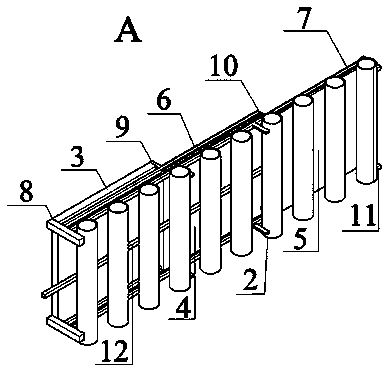

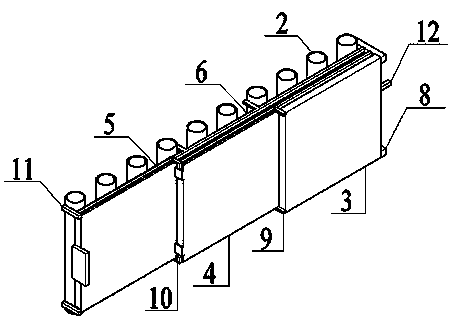

[0021] Such as figure 1 As shown, the movable heat shield structure of the present invention that can adjust the furnace temperature is suitable for small industrial pulverized coal boilers. The heat shield includes an outer fixed heat shield 3, a middle heat shield 4, an inner heat shield 5, Middle layer fixed guide groove 6, inner layer fixed guide groove 7, left fixed support steel 8, left angle steel fixed piece 9, right angle steel fixed piece 10, right fixed support steel 11, push-pull rod 12, roller 13, heat insulation The plates are all made of microporous ceramics, which have the characteristics of high temperature resistance, small thermal conductivity, and light weight.

[0022] Such as Figure 2 ~ Figure 4 As shown, an inner fixed guide groove 7 is installed on one side of the water wall 2, and the inner fixed guide groove 7 is fixed betwe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap