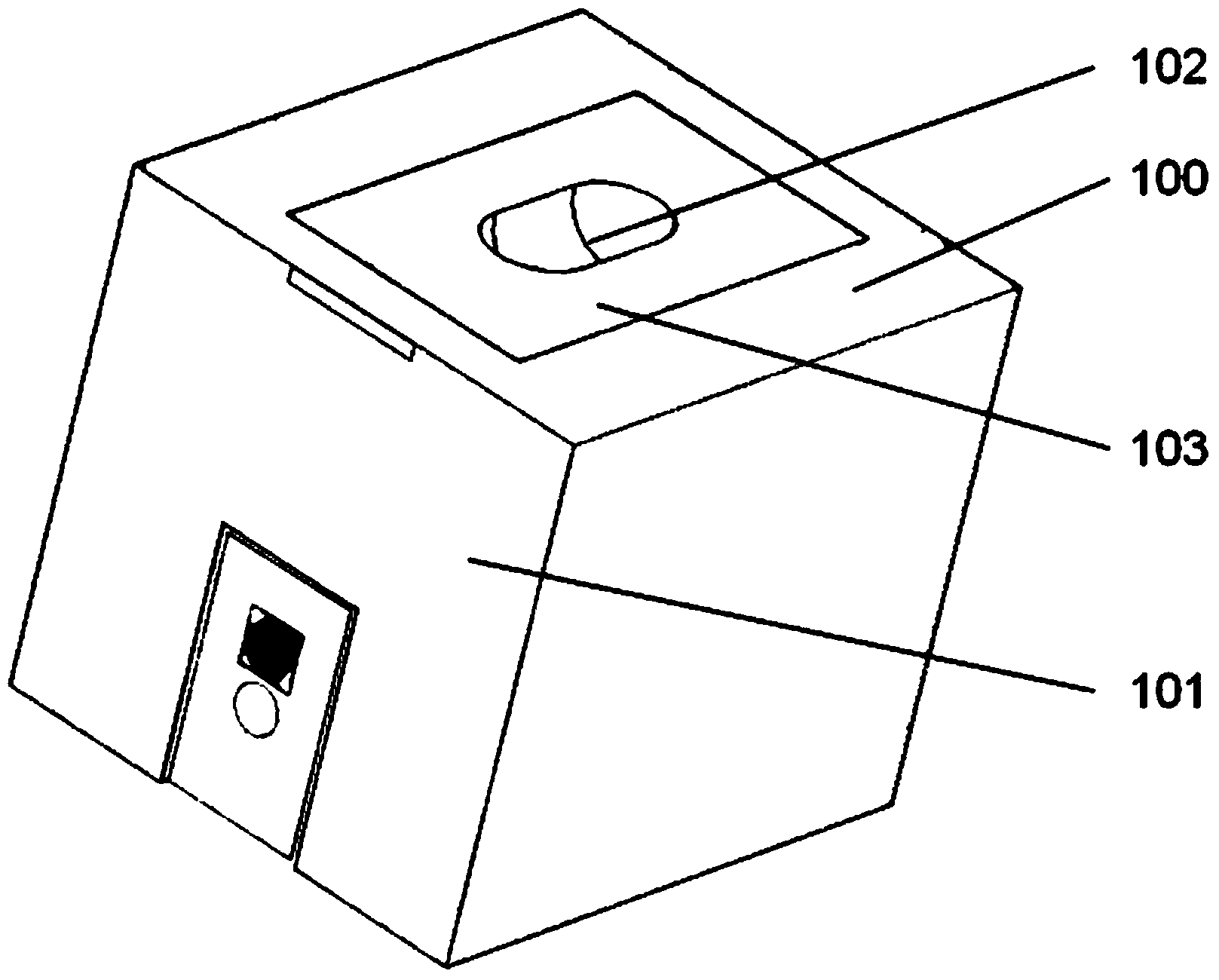

Medium resonant cavity for microwave plasma lamp

A technology of dielectric resonant cavity and microwave plasma, which is applied to the parts of gas discharge lamps, discharge lamps, electrical components, etc., can solve the problems of easy bursting of dielectric resonant cavity, achieve the goal of reducing weight, increasing electric field and improving yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

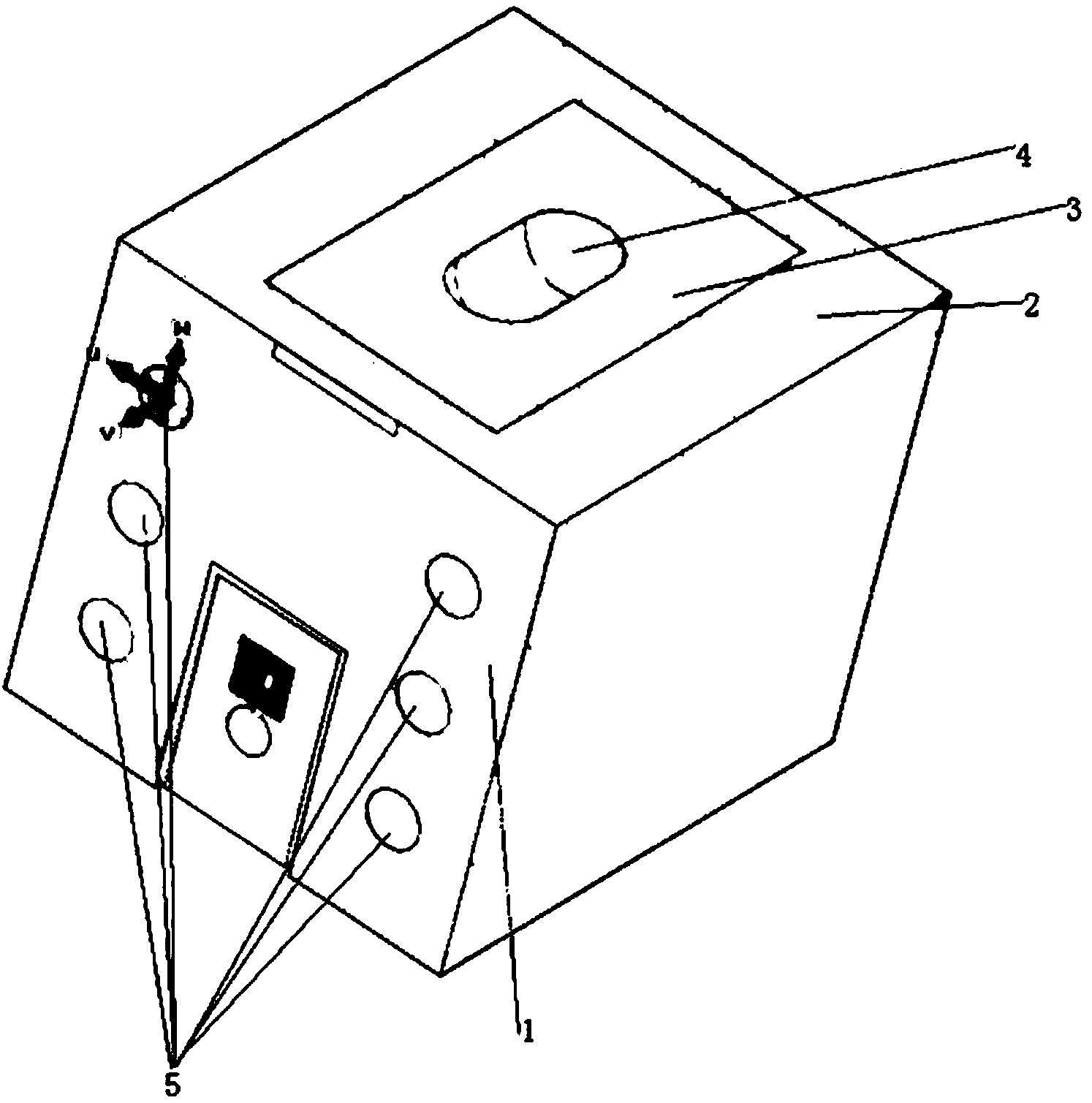

Embodiment 1

[0021] Embodiment 1: as figure 2 As shown, the hole is circular, penetrating the front and rear faces, the hole radius is 3 mm, and 3 holes are evenly arranged at both ends of the dielectric resonant cavity.

[0022] We use CST Microwave Studio to carry out full three-dimensional simulation calculations on these two structures, and find that the resonant frequency of the structure without holes is 438.4MHz, while that of the structure with holes is 440.8MHz, and the relative change rate of the resonant frequency is 0.55%. The influence of the operating frequency of the microwave plasma lamp is almost negligible.

[0023] The electric field intensity at the center of the bulb placement position is 16000V / m for the open-hole structure, and the electric field intensity for the open-hole structure is increased to 17000V / m, which is more conducive to the start-up and energy exchange of the plasma lamp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com