Chromium target production method

A manufacturing method and technology of chromium target material, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of expensive mold, easy loss, and the purity can not meet the sputtering process, so as to improve the purity, Excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

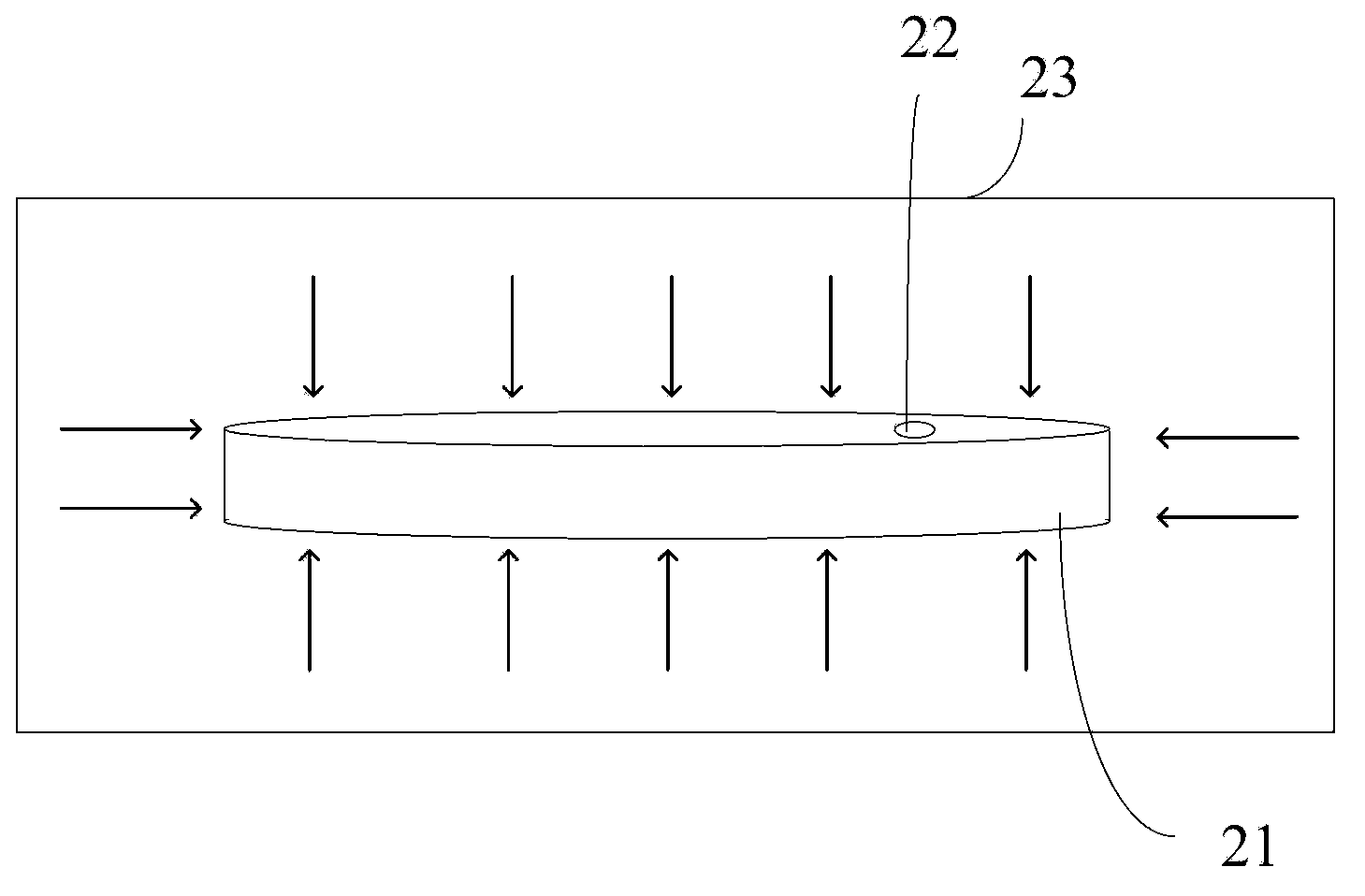

[0027] The inventors have found and analyzed that the existing hot pressing process is generally to pack the prepared chromium powder into the mold. The hot pressing process is one-way pressure, which will exceed the pressure bearing limit of the mold on the one hand, and on the other hand, cause the grains of the chromium powder to be stressed unevenly in all directions, and the internal structure of the formed chromium target is not uniform enough, and the grains Large size. Furthermore, with the hot pressing process, because the graphite mold is fragile, the process of filling the graphite mold with chromium powder is a small amount of multiple fillings. Each filling will pollute the chromium powder and affect the purity of the subsequent chromium target.

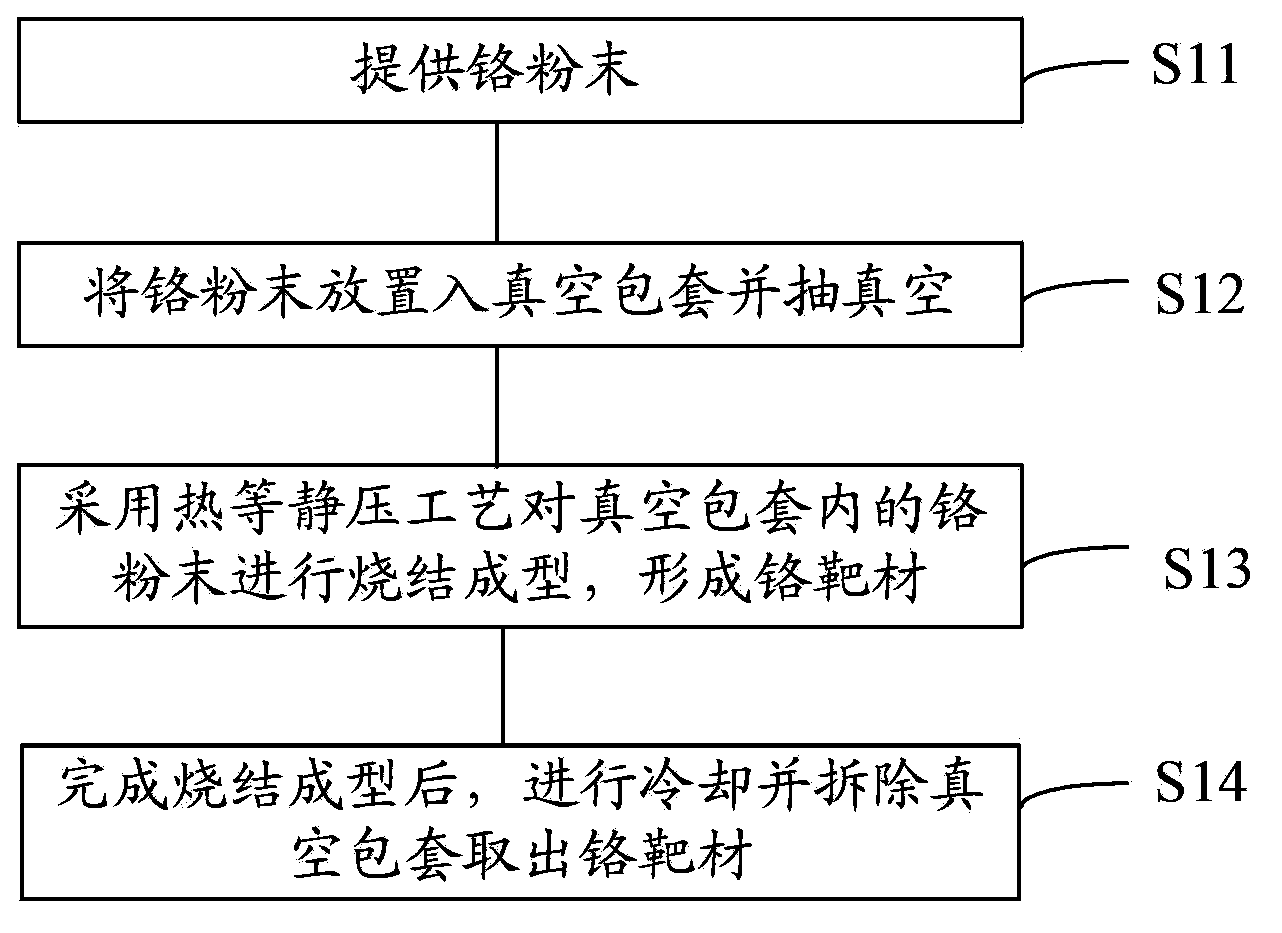

[0028] After creative work, the inventor proposed a new method for making chromium targets. figure 1 For the flow chart of the production method of the chromium target material provided by the present invention, please ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com