An ultrasonic arc hybrid welding device

A hybrid welding and ultrasonic arc technology, used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of weakening the arc space acoustic radiation ability, the arc is not stable enough, and the energy attenuation is severe, so as to reduce the sound scattering effect and reduce the The effect of migrating and suppressing low-order harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

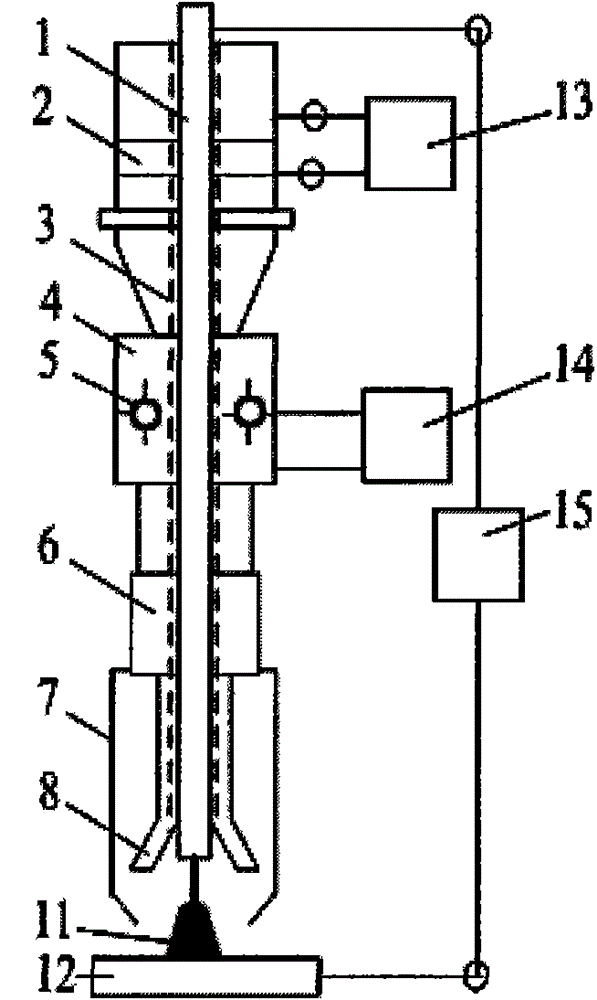

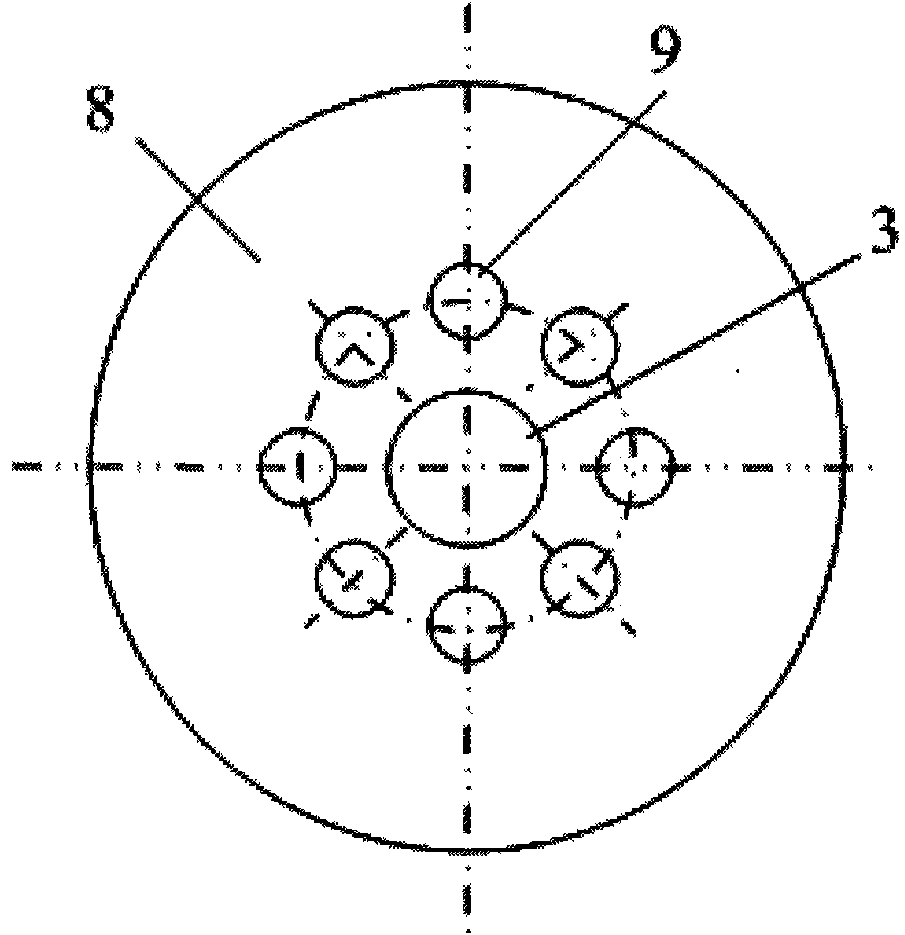

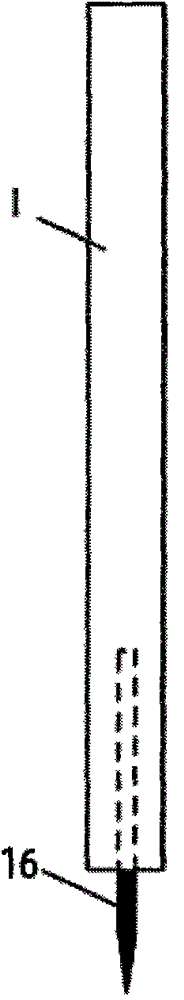

[0018] An ultrasonic arc hybrid welding device, comprising a conductive rod 1, an ultrasonic transducer 2, a first-stage ultrasonic horn 4, a welding nozzle 7, a melting electrode 10, an ultrasonic power source 13, a water cooling system 14 and a welding power source 15, the device It also includes a second-stage ultrasonic horn 6 and an ultrasonic transmitting end 8. The ultrasonic transducer 2 is tightly connected to the first-stage ultrasonic horn 4 through bolts, and the first-stage ultrasonic horn 4 is connected to the second-stage ultrasonic horn through bolts. The ultrasonic horn 6 is tightly connected, and the second-stage ultrasonic horn 6 is tightly connected to the ultrasonic emitting end 8 through bolts. The ultrasonic emitting end 8 is wrapped with a welding nozzle 7, and the lower end of the ultrasonic emitting end 8 is in the shape of a bell mouth. A plurality of ventilation holes 9 are opened on the bell mouth, an ultrasonic power supply 13 is connected to the u...

Embodiment 2

[0020] The device of this embodiment is the same as that of Embodiment 1, the difference is that the electrode used is a non-melting electrode, the conductive rod 1 is a solid electrode, and the non-melting electrode is embedded under the conductive rod 1 and closely connected with it.

Embodiment 3

[0022] The mechanical vibration generated by the transducer is firstly amplified by the first-stage ultrasonic horn, and then enters the second-stage amplification. It is radiated in the form of ultrasonic waves through the concave horn-shaped ultrasonic transmitter, which can achieve greater ultrasonic energy. Into the arc space. By opening a certain number of ventilation holes on the ultrasonic emitting end, the problem of insufficient welding protection effect can be effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com