Imidazoles ionic liquid and ionic liquid electrolytic solution, and preparation methods and applications thereof

A technology of ionic liquids and imidazoles, which is applied in the manufacture of electrolyte batteries, sulfonate salts, sulfonic acid amides, etc., can solve the problems of low specific capacity and conductivity of ionic liquids, limited applications, etc., and achieve excellent electrochemical performance. , the reaction is easy to control, the effect of safety is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

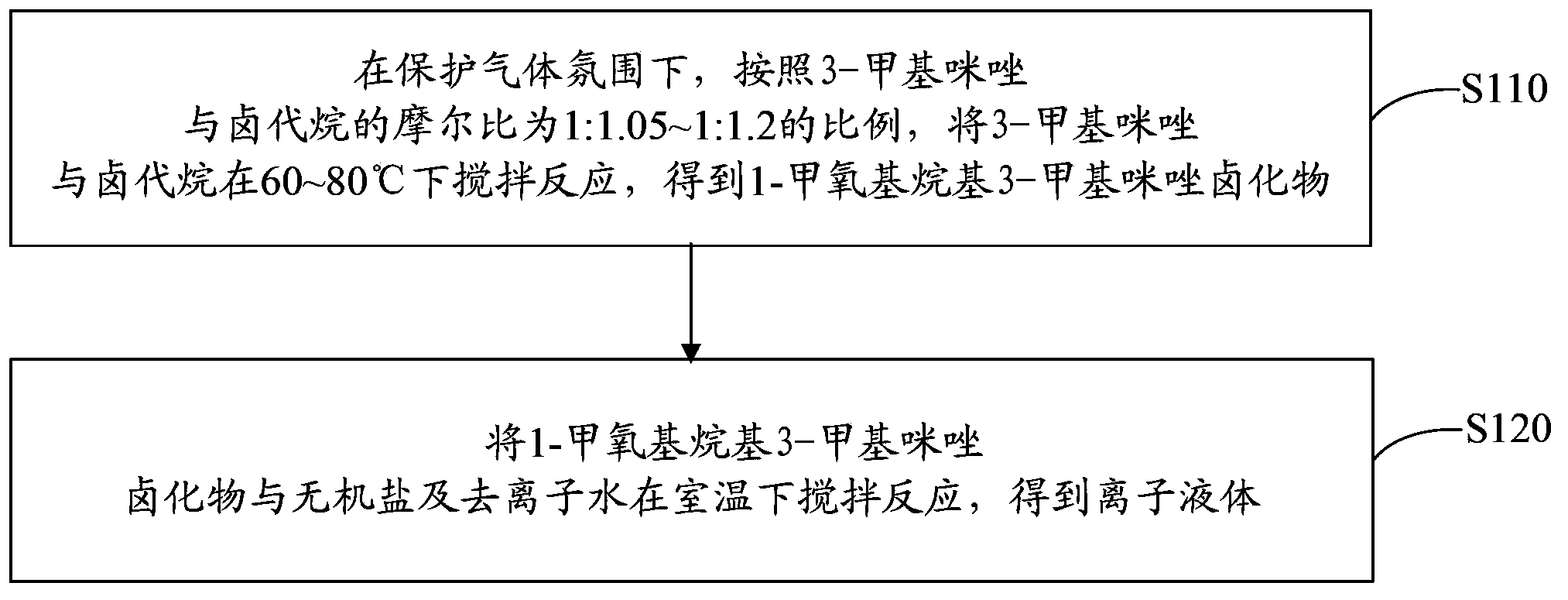

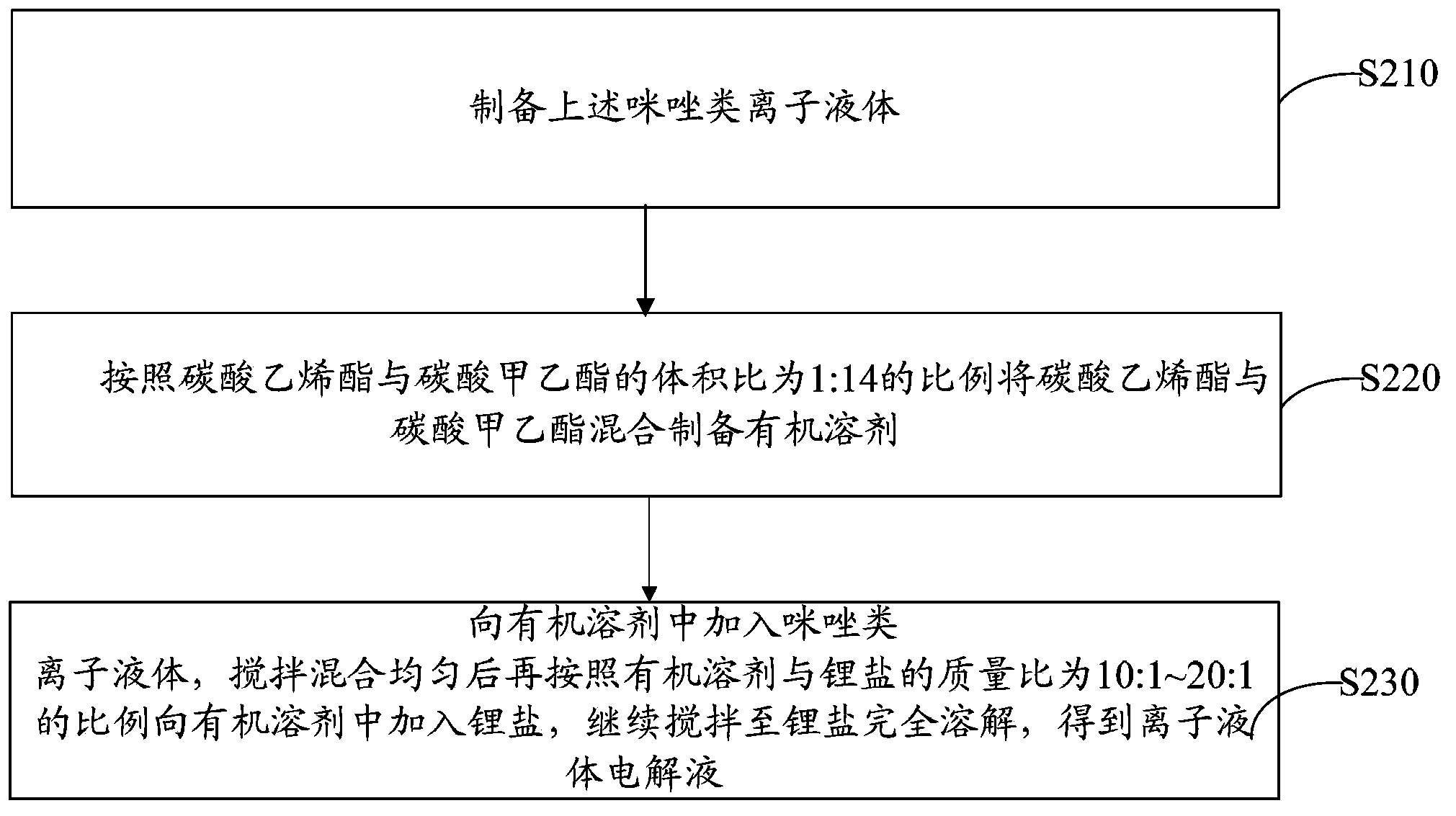

[0049] In addition, this embodiment also provides a preparation method of imidazole ionic liquid, such as figure 1 shown, including the following steps:

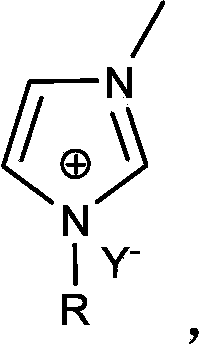

[0050] Step S110, under a protective gas atmosphere, according to the molar ratio of 3-methylimidazole and haloalkane in the ratio of 1:1.05 to 1:1.2, stirring and reacting 3-methylimidazole and haloalkane at 60-80°C to obtain 1-methoxyalkyl 3-methylimidazolium halides of the following structural formula:

[0051]

[0052] Among them, RX is haloalkane, R is CH 3 O(CH 2 ) n , n is 2, 3 or 4, X is halogen.

[0053] The obtained product containing 1-methoxyalkyl 3-methylimidazole halide can be washed with ethyl acetate for 2 to 3 times, and then dried under vacuum at 80°C to obtain purified 1-methoxyalkyl-3-methylimidazole imidazolium halides.

[0054] In other preferred embodiments, the molar ratio of 3-methylimidazole to alkyl halide is 1:1.2.

[0055] Step S120, stirring and reacting 1-methoxyalkyl 3-methylimidazol...

Embodiment 1

[0073] Add 1mol 3-methylimidazole and 1.1mol methoxyl ethyl chloride respectively in the flask of 250mL, obtain mixture; 2Under the protection of the atmosphere, the above mixture was stirred and reacted at 70°C for 40 hours to obtain a reaction product; the above reaction product was left to cool to room temperature, and then washed three times with ethyl acetate; the reaction product washed with ethyl acetate Place it at 80°C and dry it under vacuum to obtain a light yellow solid, which is 1-methoxyethyl 3-methylimidazolium chloride salt. Calculate the yield, and the yield is 82%.

[0074] Add 0.53mol NaBF to a 250mL flask 4 , 130 mL of deionized water and 0.5 mol of the 1-methoxyethyl 3-methylimidazolium chloride salt prepared above to obtain a mixed solution; the above mixed solution was stirred and reversed at room temperature for 8 hours to obtain a reacted solution; Extract the reacted solution with 250 mL of dichloromethane three times, combine the extract phases, an...

Embodiment 2

[0077] In a 250mL flask, 1mol 3-methylimidazole and 1.05mol methoxybromopropane were respectively added to obtain a mixture; under the protection of Ar atmosphere, the above mixture was stirred and reacted at 60°C for 60 hours to obtain a reaction product; The above reaction product was left to cool to room temperature, and then washed three times with ethyl acetate; the reaction product washed with ethyl acetate was vacuum-dried at 80°C to obtain a light yellow solid, namely 1-methoxypropyl 3-Methylimidazolium bromide; calculated yield, the yield was 80%.

[0078] Add 0.5mol KPF to a 250mL flask 6 , 100 mL of deionized water and 0.5 mol of the 1-methoxypropyl 3-methylimidazolium bromide prepared above to obtain a mixed solution; stirring the above mixed solution at room temperature for 20 hours to obtain a reacted solution; Extract the reacted solution with 250 mL of dichloromethane three times, combine the extract phases, and then back-extract with 60 mL of deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com