Polyolefin composition for preparing millipore membrane and preparation method thereof and millipore membrane prepared from polyolefin composition

A polyolefin and composition technology, applied in the field of microporous membranes, can solve the problems of low stretching rate and lower production efficiency, and achieve the effects of high relative dispersion, pollution avoidance, and low room temperature xylene soluble content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1. Modification of diatomite with silane coupling agent: Weigh a certain amount of silane coupling agent KH-550 (γ-aminopropyltriethoxysilane, industrial grade, Hubei New Blue Sky New Material Co., Ltd. ) was hydrolyzed in 95%wt ethanol solution for 1h until clarified to obtain a silane coupling agent hydrolyzate with a coupling agent concentration of 5wt%. Diatomite slurry with a concentration of 20%wt (a suspension formed of diatomite in water, diatomite is a diatomite product produced by Celite Company with a brand name of super floss, with a particle size range of 0.1-20 μm) is heated to 90°C, add silane coupling agent hydrolyzate, react for 2 hours and then filter with suction; then dry at 110°C for 2 hours; finally sieve to obtain modified diatomite.

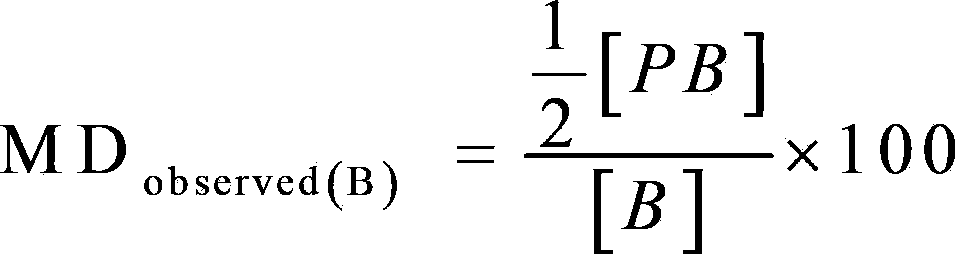

[0078] 2. Preparation of polyolefin composition: take the above-mentioned modified propylene-butene-1 random copolymer and diatomaceous earth according to a weight ratio of 50 / 50, and fully mix them in a high-speed ...

Embodiment 2

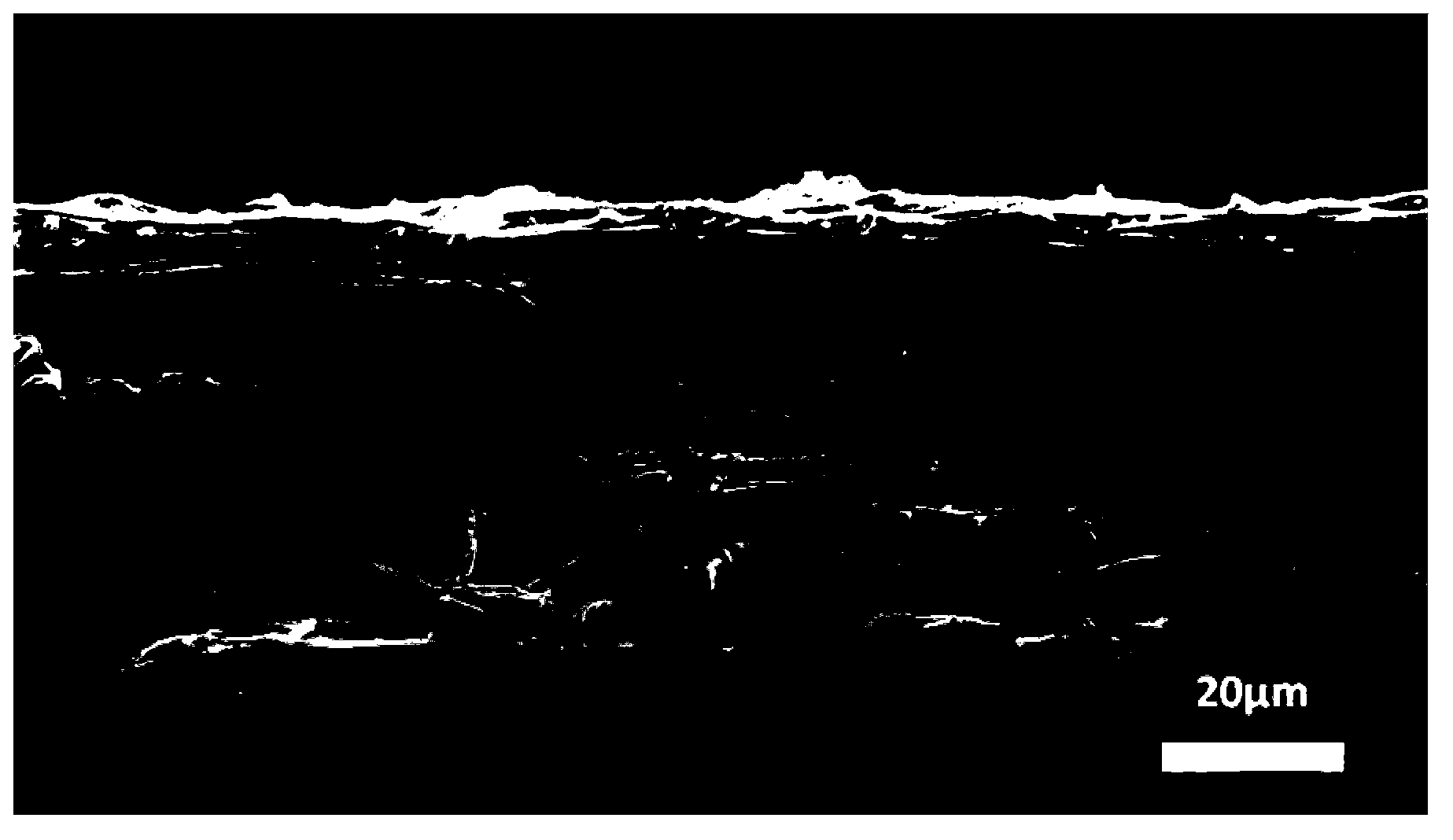

[0092] Same as Example 1, except that the extruded film is biaxially stretched, the stretching rate is 7 times / second, and the transverse and longitudinal stretching ratios are 4 times at 150°C. No membrane rupture. The obtained microporous membrane has a thickness of 30 μm and a pore diameter ranging from 1 to 12 μm.

Embodiment 3

[0094] Same as Example 1, except that the propylene-butene-1 random copolymer is taken out according to the weight ratio of 40 / 60 with diatomaceous earth. No membrane rupture. The membrane thickness is 50 μm, and the pore size ranges from 1 to 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com