Blue borate phosphor powder excited by near ultraviolet and preparation method thereof

The technology of blue phosphor and borate is applied in the field of near-ultraviolet excited borate blue phosphor and its preparation, which can solve the problem of high cost of blue phosphor, achieve low cost, stable product performance and high energy efficiency. less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

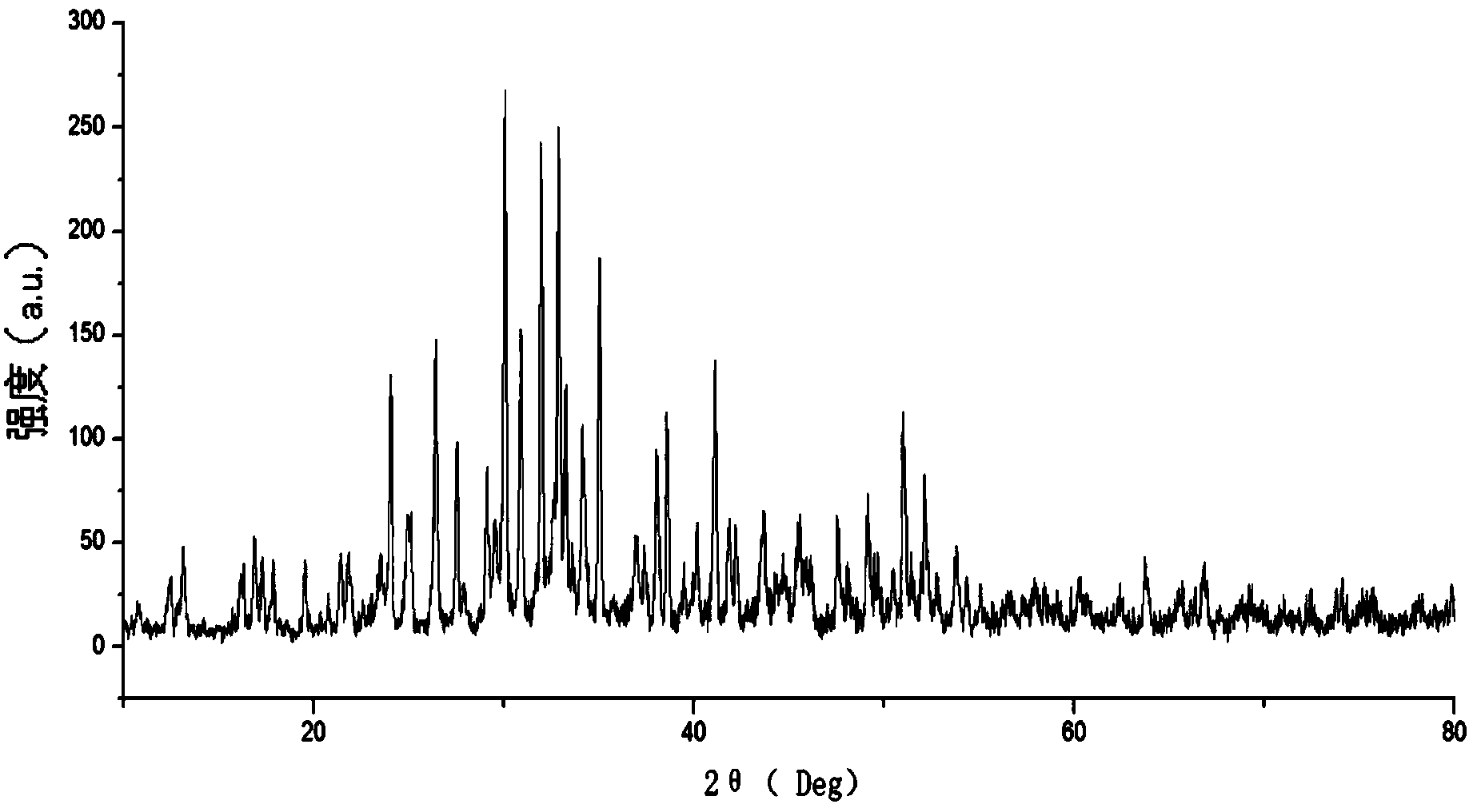

Method used

Image

Examples

Embodiment 1

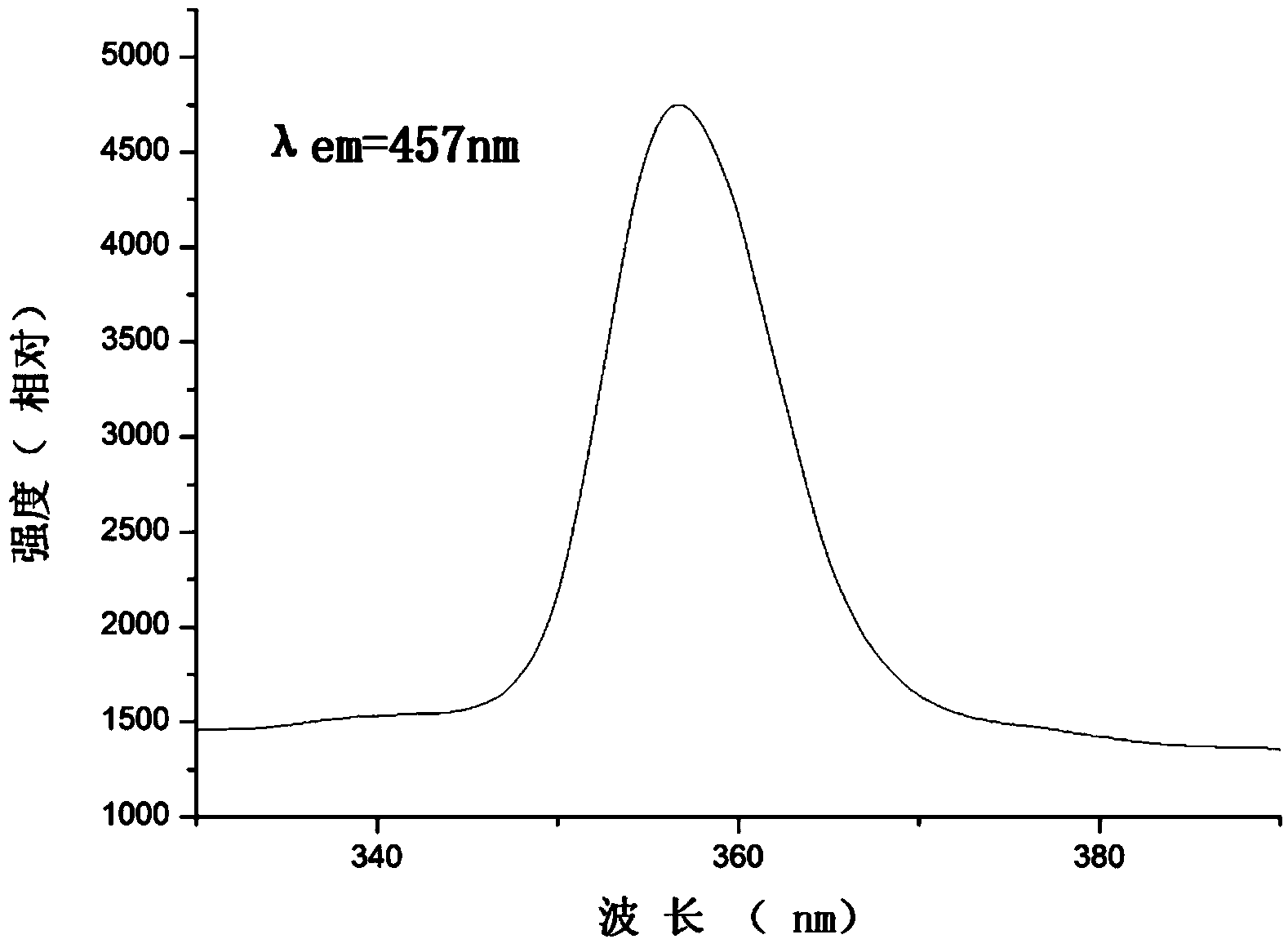

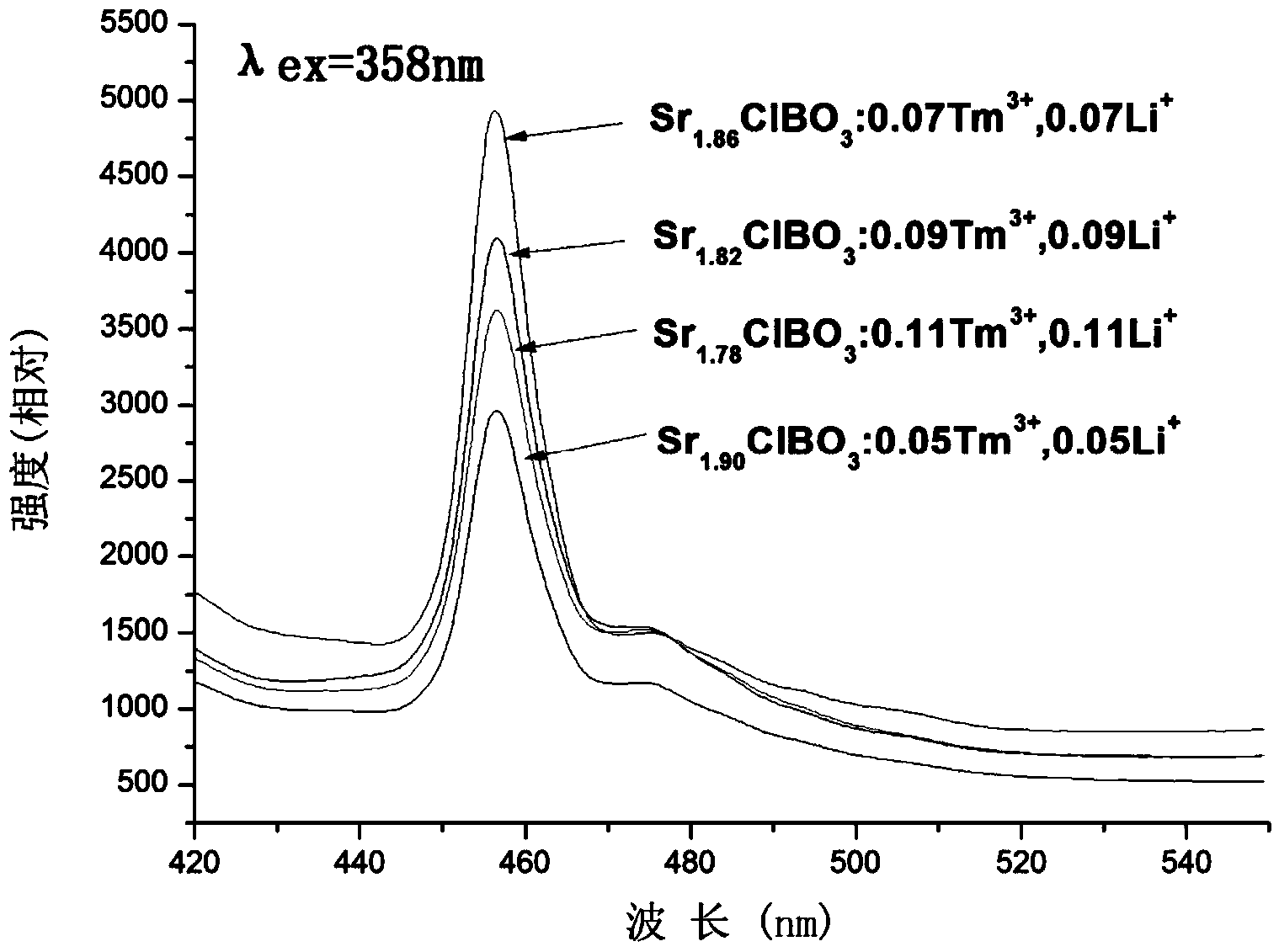

[0030] Sr 2-2x ClO 3 : 0.07Tm 3+ , 0.07Li + Near-UV Excited Borate Blue Phosphors

[0031] According to the raw material ratio of above-mentioned general formula as shown in the following table:

[0032] raw material

h 3 BO 3

Sr 2 CO 3

SrCl 2 ·6H 2 o

T m 2 o 3

Li 2 CO 3

weight

0.3174g

1.0037g

0.6666g

0.0675g

0.0129g

[0033] (1) Accurately weigh the above raw materials, fully grind them in an agate crucible for 20 minutes to obtain a fine powder with uniform particles, mix them evenly and put them into a ceramic crucible.

[0034] (2) Put the above-mentioned fine powder into the muffle furnace according to the set procedure, first raise the temperature from room temperature to 400°C for 60 minutes after 70 minutes, and then raise it to 800°C for 6 hours after 90 minutes. After the furnace is cooled to room temperature and taken out, it is ground into powder with an agate crucible to obtain...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap