Method of extracting xylo-oligosaccharide from bamboo shoot shells and separating to obtain xylo-oligosaccharide monomer

A technology of xylooligosaccharides and bamboo shoot shells, applied in the field of biochemistry, can solve problems such as the separation method of xylooligosaccharide monomers that have not been seen, and achieve the effects of low cost, simple and fast operation, and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Method

[0037] 1. Extraction of xylooligosaccharides

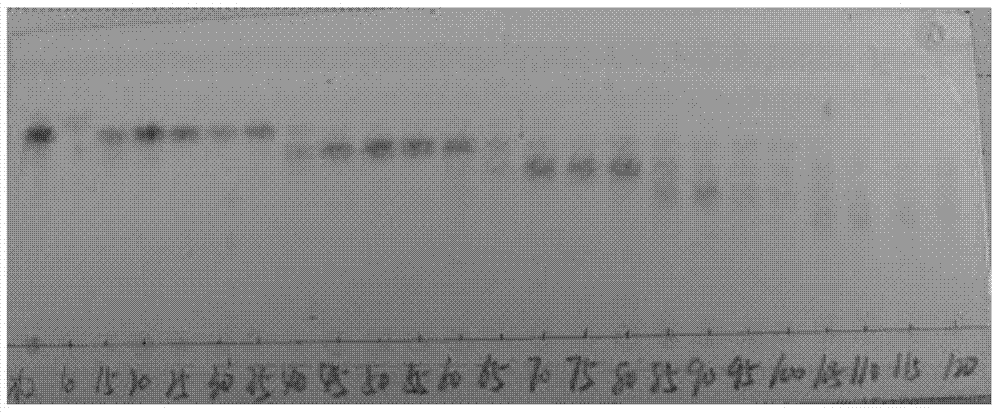

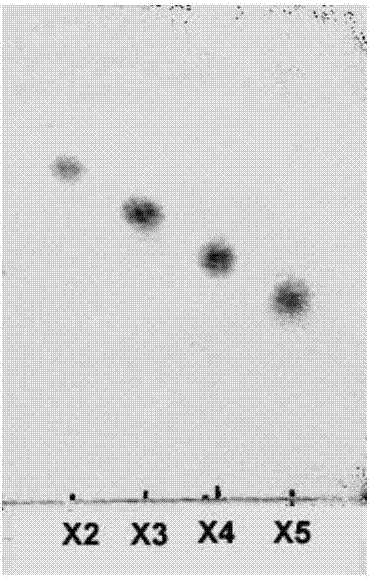

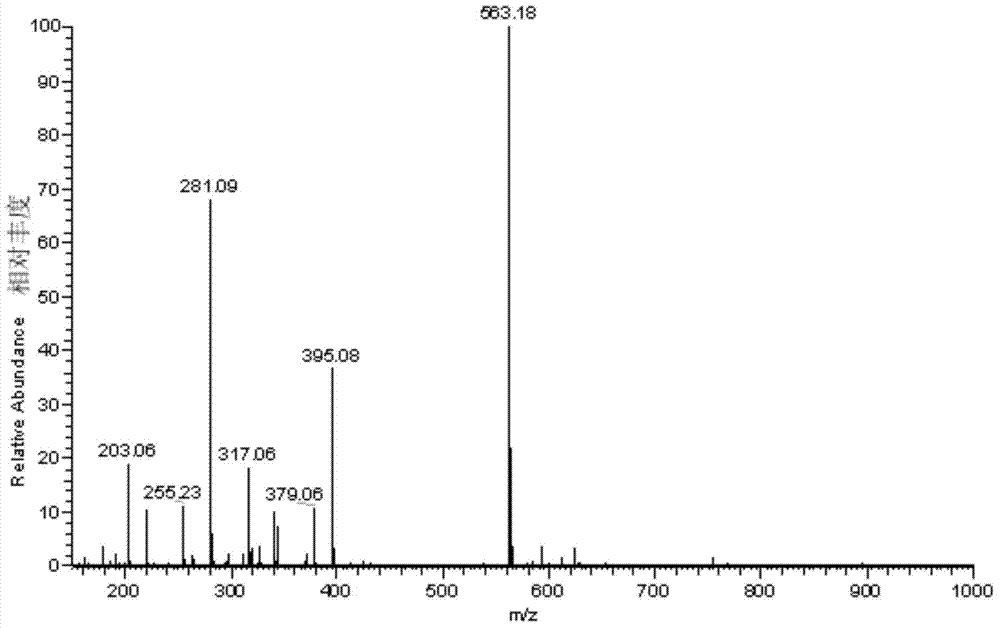

[0038] Weigh bamboo shoot shells and add 10 times the volume of 6mol / L NaOH solution, soak at 60°C for 12h, wash with water until the pH value is about 8.0, and dry in an oven at 60°C until constant weight. Accurately weigh 2g of the dried sample into the digestion tank, add 50ml of distilled water, cover and seal it, and then degrade it in the digestion furnace. The microwave power is 700W, and the digestion time is 8min. The supernatant was taken as the crude xylan solution, and the xylan content was determined therein. Then add xylanase to the crude xylan solution, the amount of enzyme added is 35 IU / g xylan, enzymatically hydrolyze in a constant temperature shaking box at 50°C for 8 hours, and take the supernatant for storage. The DNS method was then used to measure the sugar content in the supernatant after enzymolysis, and at the same time determine the content of each xylooligosaccharide.

[0039] 2. M...

Embodiment 2

[0066] 1. Method

[0067] 1. Extraction of xylooligosaccharides

[0068] Weigh bamboo shoot shells and add 10 times the volume of 6mol / L NaOH solution, soak at 60°C for 12h, wash with water until the pH value is about 8.0, and dry in an oven at 60°C until constant weight. Accurately weigh 2g of the dried sample into the digestion tank, add 50ml of distilled water, cover and seal it, and then degrade it in the digestion furnace. The microwave power is 600W, and the digestion time is 10min. The supernatant was taken as the crude xylan solution, and the xylan content was determined therein. Then add xylanase to the crude xylan solution, the amount of enzyme added is 60 IU / g xylan, enzymolyze it in a constant temperature shaking box at 50°C for 6 hours, and take the supernatant for storage. The DNS method was then used to measure the sugar content in the supernatant after enzymolysis, and at the same time determine the content of each xylooligosaccharide.

[0069] 2. Mobile pha...

Embodiment 3

[0094] 1. Method

[0095] 1. Extraction of xylooligosaccharides

[0096] Weigh bamboo shoot shells and add 10 times the volume of 6mol / L NaOH solution, soak at 60°C for 12h, wash with water until the pH value is about 8.0, and dry in an oven at 60°C until constant weight. Accurately weigh 2g of the dried sample into the digestion tank, add 50ml of distilled water, cover and seal it, and degrade it in the digestion furnace. The microwave power is 800W, and the digestion time is 6min. After cooling, take it out, and finally dilute it to 100ml with distilled water The supernatant was taken as the crude xylan solution, and the xylan content was determined therein. Then add xylanase to the crude xylan solution, the amount of enzyme added is 10IU / g xylan, enzymolyze it in a constant temperature shaking box at 50°C for 10h, and take the supernatant for storage. The DNS method was then used to measure the sugar content in the supernatant after enzymolysis, and at the same time deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com