Perpendicular shaft wind turbine with adjustable windward area

A technology with a windward area and a vertical axis, which is applied to wind turbines, wind turbines, and wind turbine components at right angles to the wind direction. and other problems to achieve the effect of improving mechanical properties, increasing working range, and avoiding braking and parking states.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

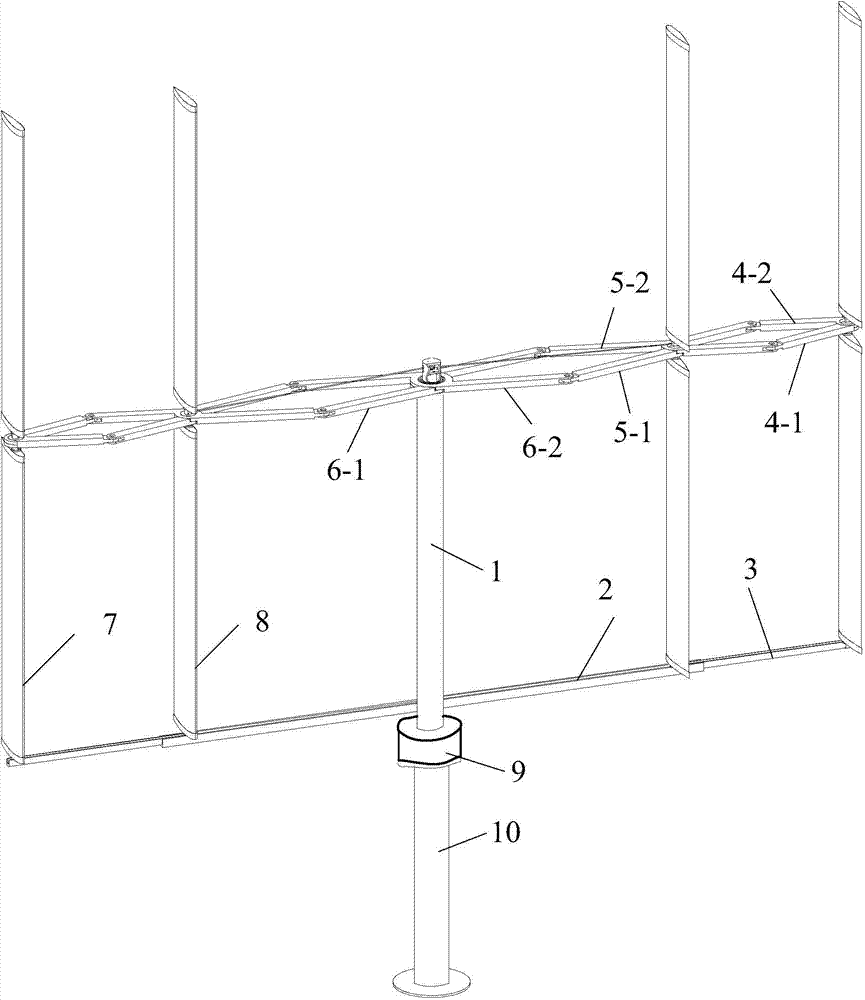

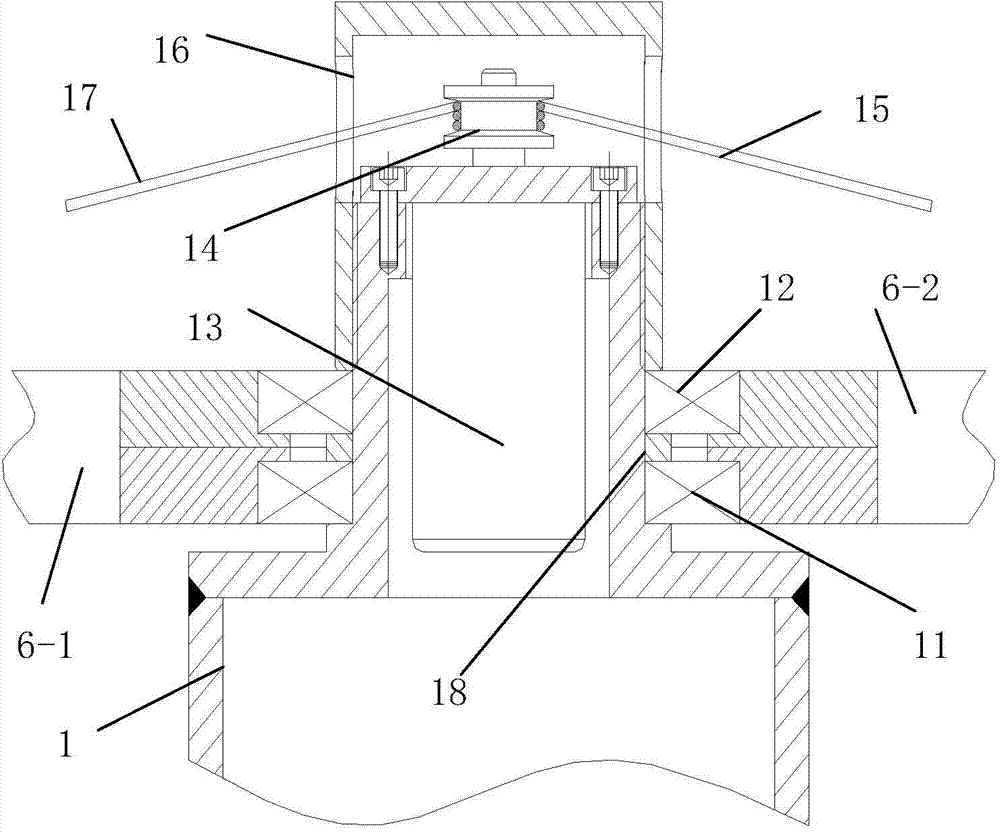

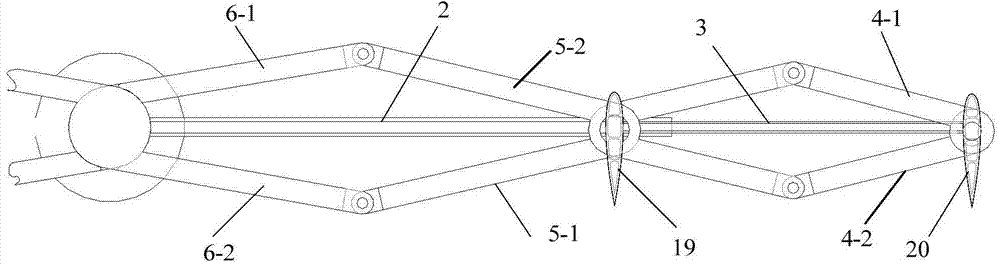

[0020] combine figure 1 with figure 2 , the generator 9 is fixed on the top of the tower 10 by bolts, the main shaft 1 and the rotor of the generator 9 are fixed; the main rod 6-1 and the main rod 6-2 form a revolving pair about the center of the main shaft 1, and the main rod 6-1 and the main rod 6-2 cooperate with the outer rings of the bearing 11 and the bearing 12 respectively, and the inner rings of the bearing 11 and the bearing 12 cooperate with the main shaft 1; a sleeve 18 is installed between the bearing 11 and the bearing 12, and the bearing 12 The outer ring of the motor is positioned by the motor cover 16, and the motor cover 16 is screwed to the main shaft 1. The servo retractable motor 13 is installed on the top of the main shaft 1 through the flange, and the sheave 14 is consolidated with the output shaft of the servo motor 13; one end of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com