Method for improving carbon content measuring accuracy in steel

A technology for measuring accuracy and carbon content, which is applied in the field of atomic emission spectrometry and can solve the problem that the measurement method cannot meet the requirements of on-site rapid measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

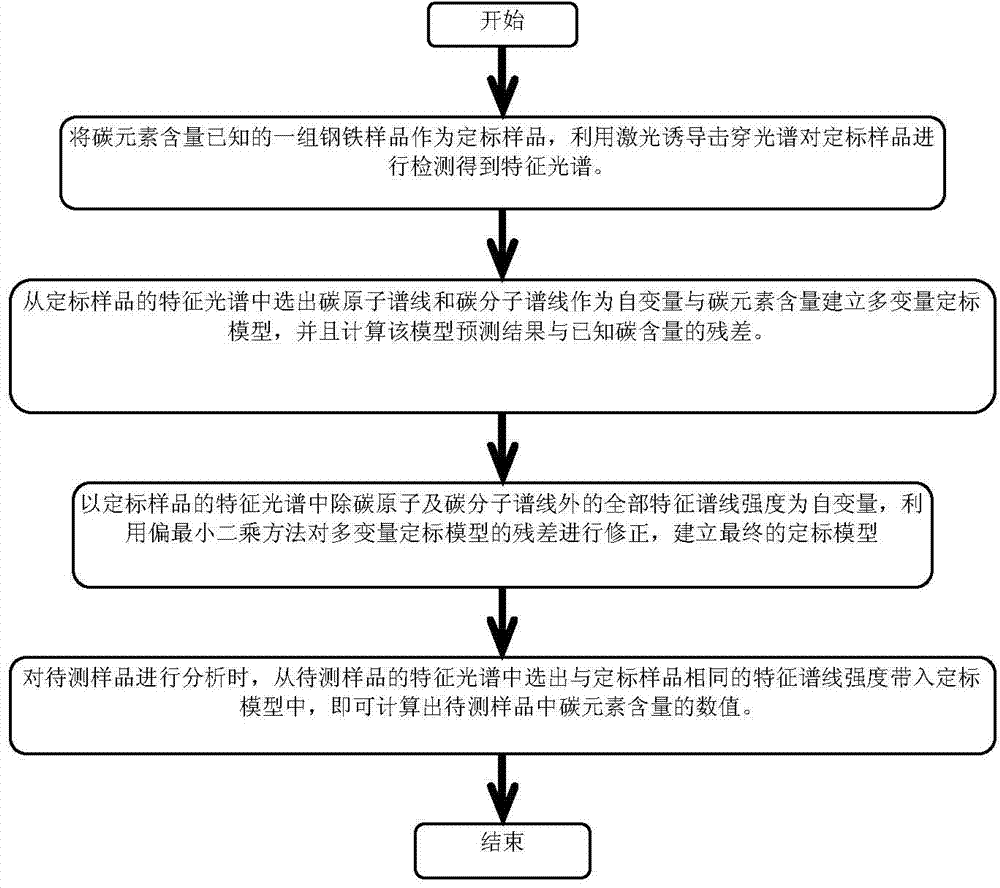

Method used

Image

Examples

Embodiment

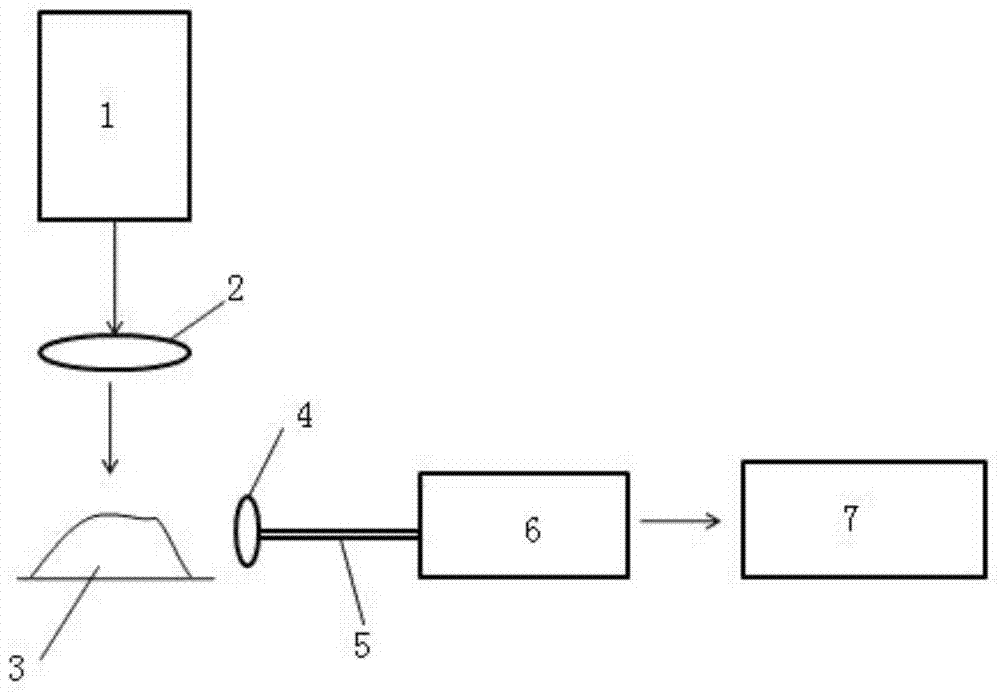

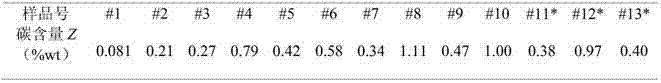

[0059] 1) Table 1 lists 13 steel samples with known carbon content Z. In this example, the first 10 steel samples are selected as calibration samples, that is, n is equal to 10, and the other three are used as prediction samples. 13 kinds of iron and steel samples were tested using the laser-induced breakdown spectroscopy measurement system: such as figure 1 As shown, a 266nm pulsed laser 1 is used as the excitation light source, and the laser energy is set to 30mJ. The laser emitted from the laser is focused by the focusing lens 2 and then acts on the surface of the sample 3. Plasma is generated at the focal point, and the radiated optical signal generated by the plasma It is collected in real time through the focusing lens 4, the delay time is set to 1 μs, and the sampling gate width is 1 ms. After passing through the optical fiber 5 and processed by the spectrometer 6, it is converted into an electrical signal and collected by the computer 7 to obtain the spectrum of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com