Wavelength converter, manufacturing method thereof and related wavelength conversion device

A technology of wavelength conversion and wavelength conversion layer, which is applied in projection devices, instruments, optics, etc., and can solve problems such as poor reflection coating effect and rough microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

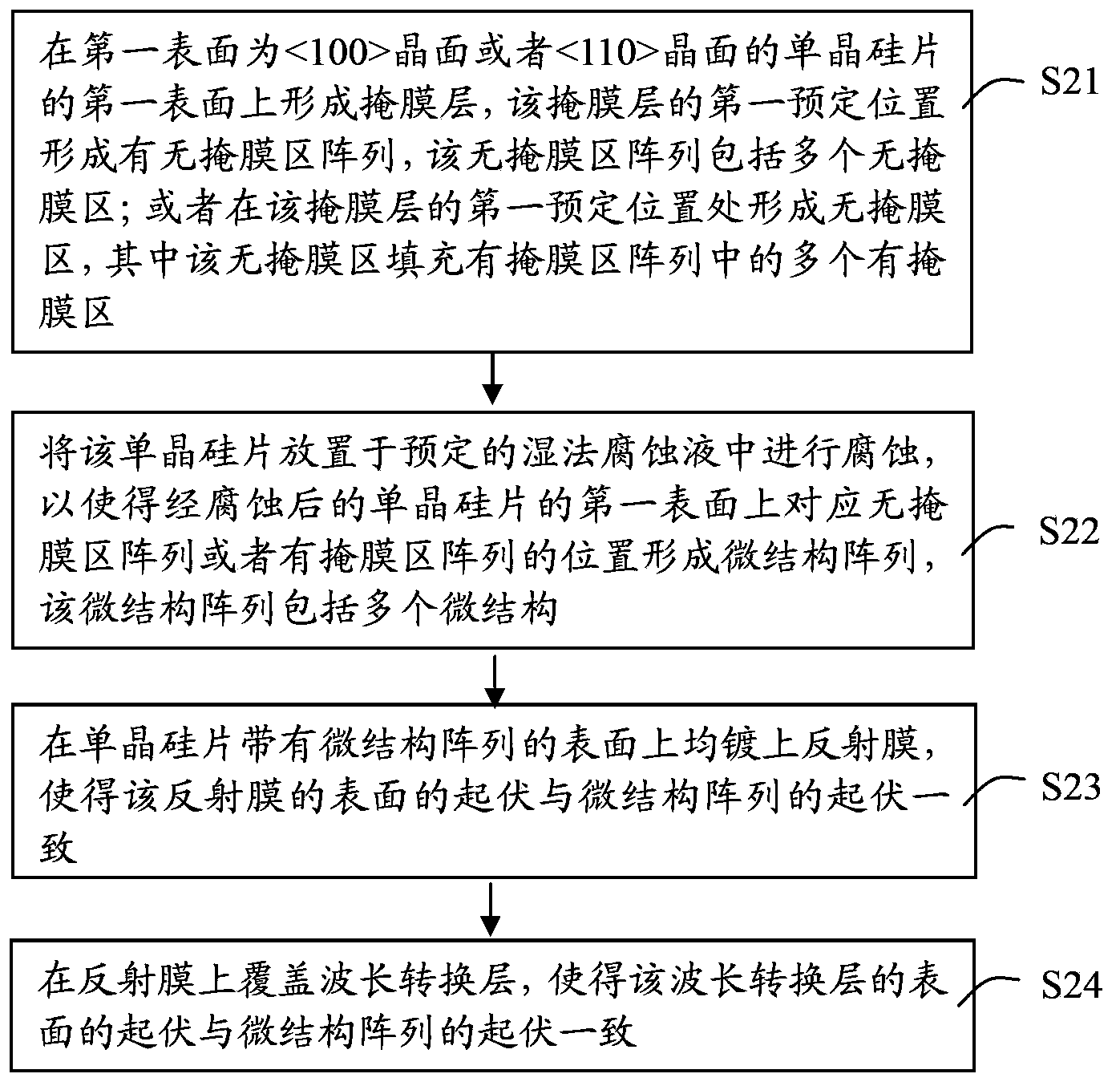

[0035] According to the relationship between the surface orientation of the single crystal silicon wafer and its single crystal lattice orientation, the single crystal silicon wafer is divided into single crystal silicon wafer, single crystal silicon wafer and single crystal silicon wafer, respectively It means that the plane direction of the surface of the silicon wafer is the crystal plane, the crystal plane and the crystal plane of the silicon single crystal. When monocrystalline silicon is etched in alkaline solution, it exhibits anisotropic corrosion characteristics, that is, different crystal planes of silicon are etched at different rates. The etchant has the fastest corrosion rate on the crystal plane, followed by the crystal plane, and finally the crystal plane. hundreds of times faster.

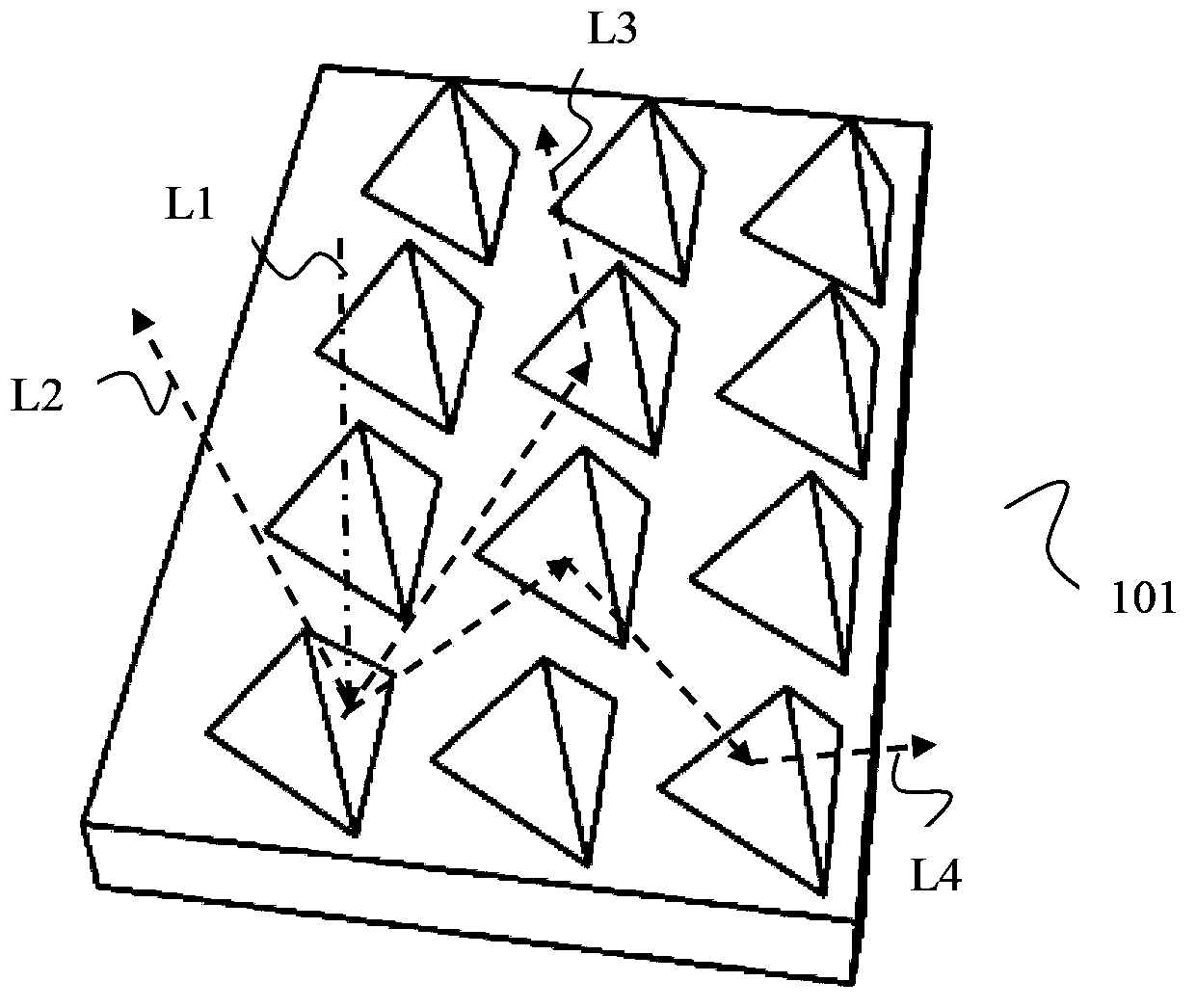

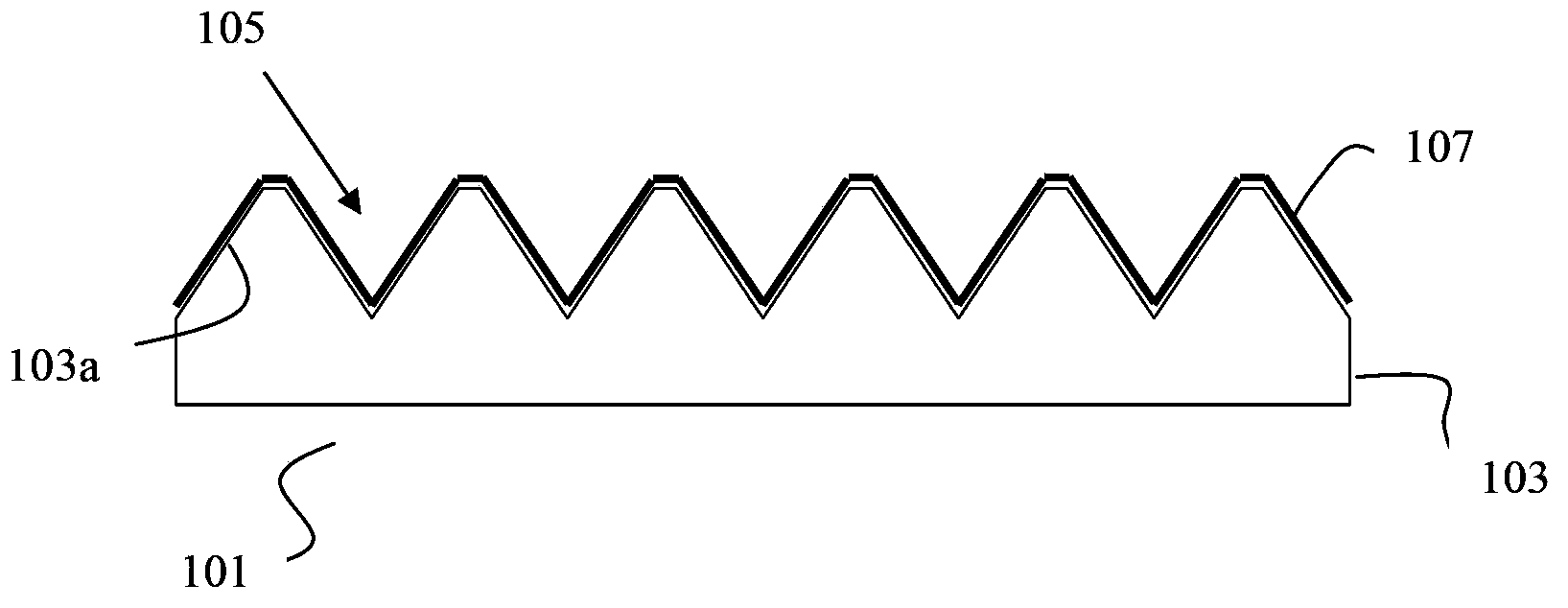

[0036] Therefore, the formation of a microstructure array on the surface of a single-crystal silicon wafer can be achieved through the huge difference in the etching speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com