Lithium ion battery and positive plate thereof

A lithium-ion battery and positive electrode technology, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problem of not being able to achieve a good heat insulation effect, and can prevent burning or explosion, reduce quality, and improve The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The positive active material is lithium cobalt oxide (LiCoO 2 ), the binder uses polyvinylidene fluoride (PVDF), the conductive agent uses conductive carbon Super-P, the solvent uses N-methylpyrrolidone (NMP), and LiCoO 2 : PVDF: Super-P is mixed in NMP at a weight ratio of 95:2:3, and a uniformly dispersed positive electrode slurry is obtained by high-speed stirring; the positive electrode slurry is coated on an aluminum foil, blown and dried, and coated by rolling. A positive electrode membrane covered with a positive electrode active material layer.

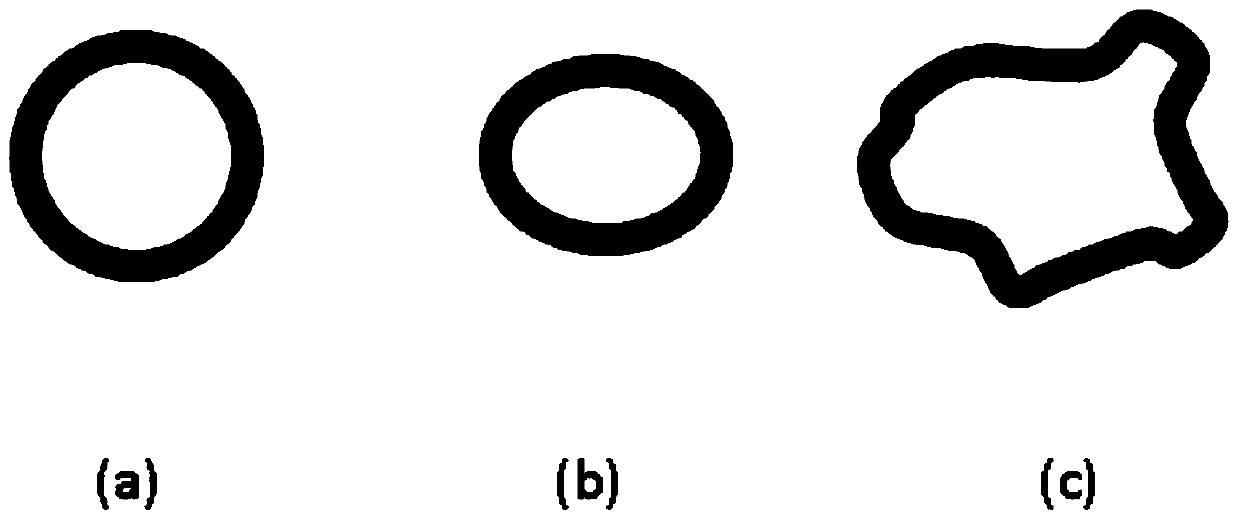

[0034] Similarly, a heat-insulating hollow particle Al with a particle size of 0.5 μm 2 o 3 As the raw material of the heat insulation layer, its hollow volume accounts for 50±5% of the volume of the entire small particle, and the selected hollow particle Al 2 o 3 Mix with binder PVDF and solvent NMP, and stir at a high speed to obtain a uniformly dispersed heat-insulating layer slurry; apply the heat-insulating lay...

Embodiment 2

[0036] The positive active material is LiCoO 2 , the binder uses polyvinylidene fluoride, the conductive agent uses conductive carbon Super-P, the solvent uses NMP, and LiCoO 2 : PVDF: Super-P is mixed in NMP at a weight ratio of 95:2:3, and a uniformly dispersed positive electrode slurry is obtained by high-speed stirring; the positive electrode slurry is coated on an aluminum foil, blown and dried, and coated by rolling. A positive electrode membrane covered with a positive electrode active material layer.

[0037]Similarly, the heat-insulating hollow particle MgO with a particle size of 0.5 μm is selected as the raw material of the heat-insulating layer, and its hollow volume accounts for 40±5% of the volume of the entire small particle. The selected hollow particle MgO is combined with the binder PVDF, solvent NMP mixed, and stirred at high speed to obtain a uniformly dispersed heat-insulating layer slurry; apply the heat-insulating layer slurry on the positive electrode ...

Embodiment 3

[0039] The positive active material is LiCoO 2 , the binder uses polyvinylidene fluoride, the conductive agent uses conductive carbon Super-P, the solvent uses NMP, and LiCoO 2 : PVDF: Super-P is mixed in NMP at a weight ratio of 95:2:3, and a uniformly dispersed positive electrode slurry is obtained by high-speed stirring; the positive electrode slurry is coated on an aluminum foil, blown and dried, and coated by rolling. A positive electrode membrane covered with a positive electrode active material layer.

[0040] Similarly, heat-insulating hollow particle aluminum silicate with a particle size of 1 μm is selected as the raw material of the heat-insulation layer, and its hollow volume accounts for 50±5% of the entire small particle volume, and the selected hollow particle aluminum silicate and binder PVDF and solvent NMP are mixed, and a uniformly dispersed heat-insulating layer slurry is obtained by high-speed stirring; the heat-insulating layer slurry is coated on the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com