Method and device for measuring light frequency through high-power optical fiber optics frequency comb

An optical frequency comb and fiber optics technology, applied in the field of laser science and technology, can solve the problems of no measurement of absolute laser frequency, limited system stability, high requirements for optical comb devices, etc., and achieve fast measurement methods, high degree of integration, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

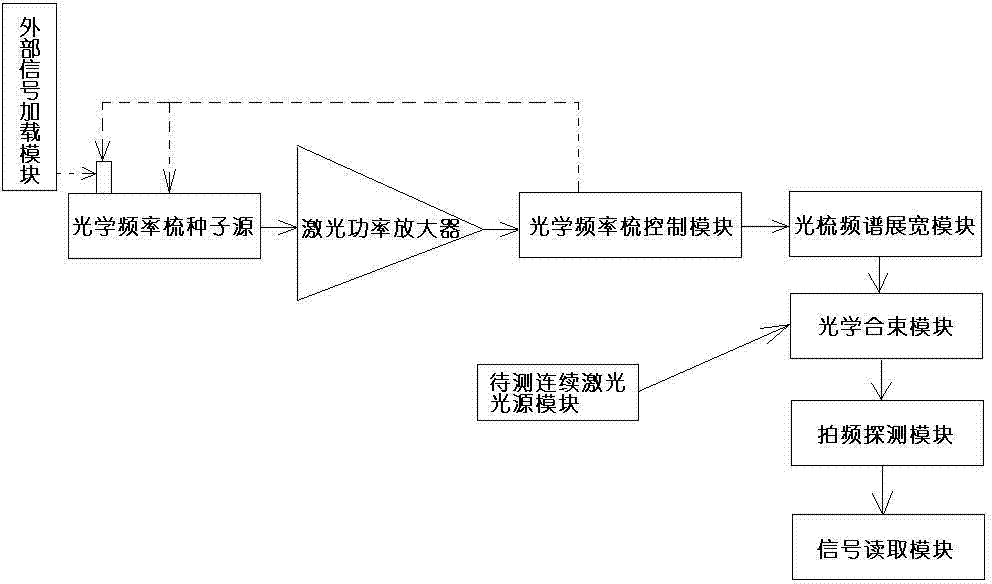

[0032] Embodiment one: if figure 1 As shown, this embodiment specifically relates to a method and device for measuring optical frequency with a high-power fiber optic frequency comb, that is, measuring figure 1 The laser frequency output by the continuous laser light source module to be tested is shown in . The device includes an optical frequency comb, an optical comb spectrum broadening module, an optical beam combining module, a beat frequency detection module and a signal reading module arranged in sequence from the beginning to the end. The optical frequency comb is composed of an optical frequency comb seed source, a laser power amplification module, and an optical frequency comb control module. There is a feedback connection relationship between the optical frequency comb control module and the optical frequency comb seed source; the optical frequency comb seed source An external signal loading module is also arranged on the top, and a continuous laser light source mo...

Embodiment 2

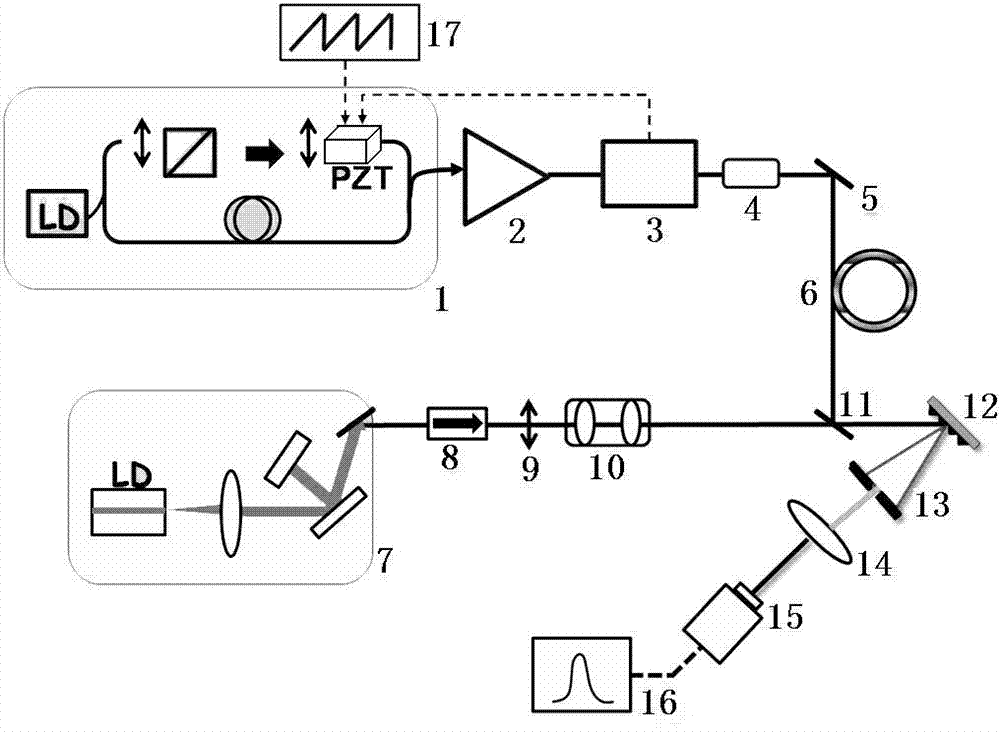

[0048] Embodiment two: if figure 2 Shown is a schematic diagram of using a polarization rotation-locked mode fiber laser as the optical frequency comb seed source, and the output light of the 657nm external cavity semiconductor laser as the laser to be measured, and measuring its optical frequency with a high-power optical frequency comb.

[0049] (1) The optical frequency comb seed source 1 adopts a half-space and half-fiber structure, using a 980nm semiconductor laser LD as a pump source, a single-mode ytterbium-doped fiber as a gain medium, and an intracavity space isolator to ensure the unidirectional operation of the laser. The ceramic crystal PZT is installed on the high reflection mirror in the cavity; the spatial wave plate in the cavity is adjusted to make the laser reach a stable mode-locked state;

[0050] (2) The laser power amplifier 2 adopts a two-stage amplification structure. The gain fiber of the pre-amplifier is a single-mode fiber doped with ytterbium, whic...

Embodiment 3

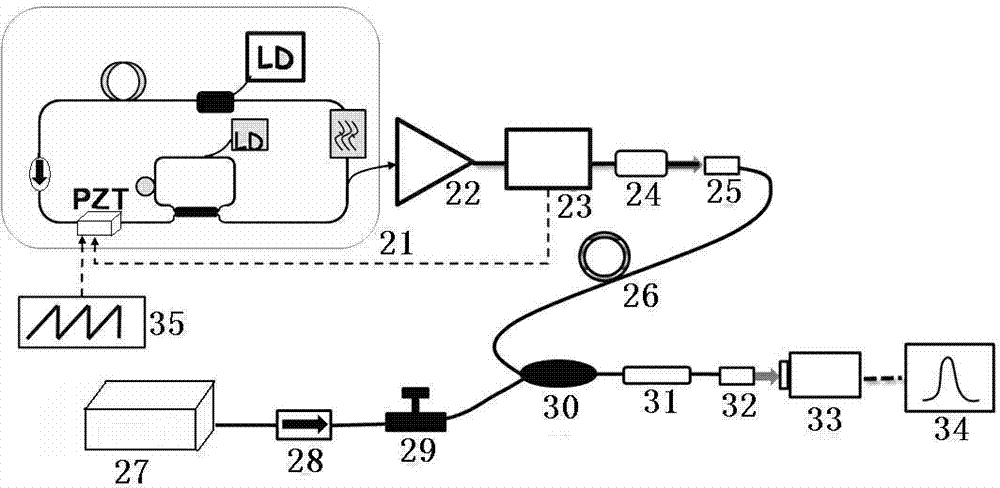

[0060] Embodiment three: as image 3 Shown is a schematic diagram of using a fiber loop mirror structure laser as the optical frequency comb seed source, using the output light of the 1064nm fiber laser as the laser to be measured, and measuring its frequency with an optical frequency comb.

[0061] (1) The optical frequency comb seed source 21 adopts a fiber optic ring mirror structure, uses a 980nm semiconductor laser LD as a pump source, and a single-mode ytterbium-doped fiber as a gain medium; piezoelectric ceramic crystal PZT is wound on the single-mode fiber of the laser cavity ; Adjust the fiber polarization controller to make the semiconductor laser LD reach a stable mode-locked state;

[0062] (2) Since the wavelength band of the laser to be measured is similar to the output light band of the optical frequency comb seed source 21, the optical fiber power amplifier 22 adopts a single-stage amplification structure, and a 1 μm band optical fiber isolator is used in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com