Micromechanical clamped beam type four-state reconfigurable microwave band-pass filter and preparation method

A technology for fixing beams and filters, applied in semiconductor/solid-state device parts, waveguide devices, image communication, etc., can solve the problems of increasing conductor and substrate loss, large inductance, and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

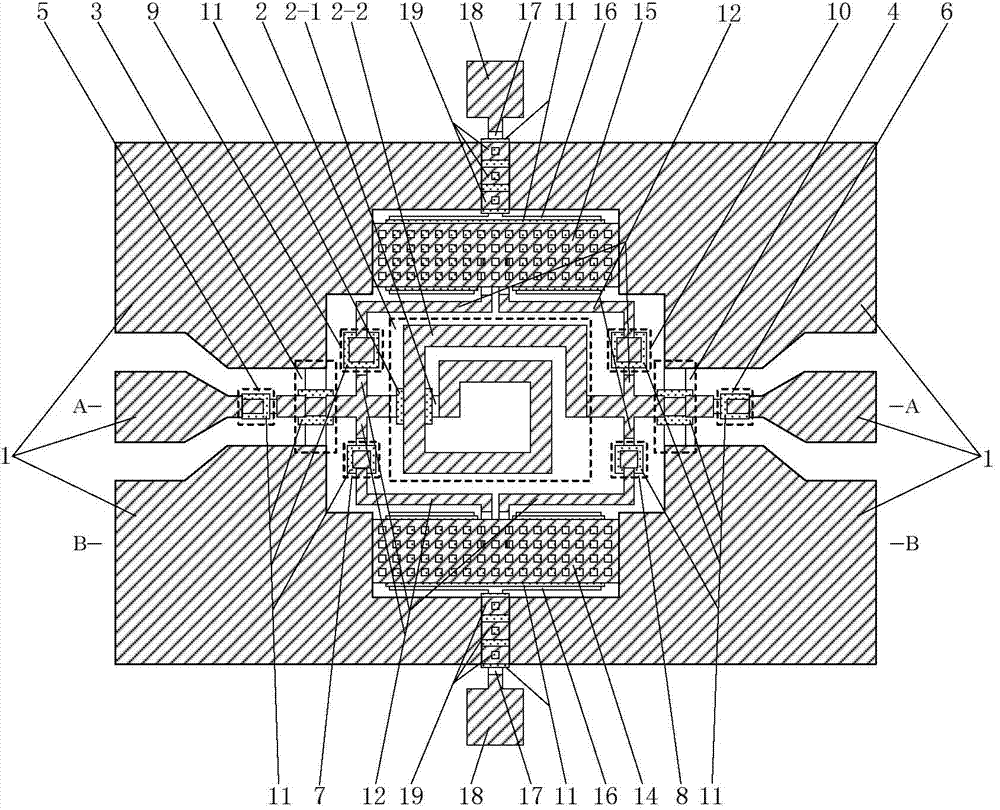

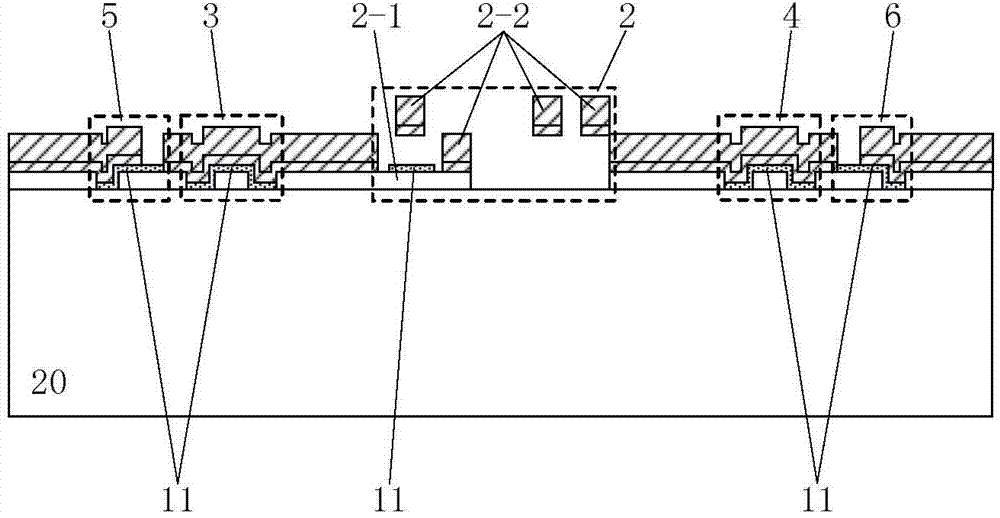

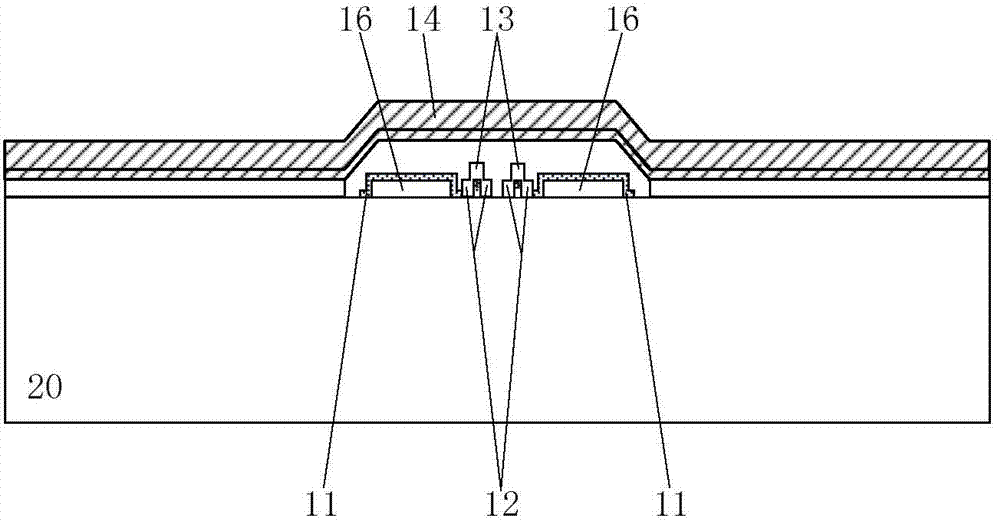

[0035] The specific implementation scheme of the four-state reconfigurable microwave bandpass filter of the micromechanical fixed beam type of the present invention is as follows:

[0036] A CPW1 with a port characteristic impedance of 50Ω, a planar spiral inductor 2, two first MIM capacitors 3 and a second MIM capacitor 4 connected in parallel between the CPW signal line and the ground line are provided on the gallium arsenide substrate 20, Two third MIM capacitors 5 and fourth MIM capacitors 6 connected in series to the CPW signal line, four fifth MIM capacitors 7 connected by leads, sixth MIM capacitors 8 , seventh MIM capacitors 9 , and eighth MIM capacitors 10 , leads 12, bumps 13, first MEMS fixed beam 14, second MEMS fixed beam 15, driving electrodes 16, connecting wires 17, pads 18 and air bridges 19:

[0037] CPW1 is composed of three lines on the same plane, wherein one line in the middle is the signal line of CPW and the two lines on both sides are ground lines of C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com