A kind of treatment equipment and method related to inorganic membrane distillation applied to waste oil products

A technology of treatment equipment and inorganic membrane, applied in the field of waste oil treatment, can solve the problems of non-recyclability, change in oil performance, low utilization rate, etc., and achieve the effects of low production cost, high recovery rate and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

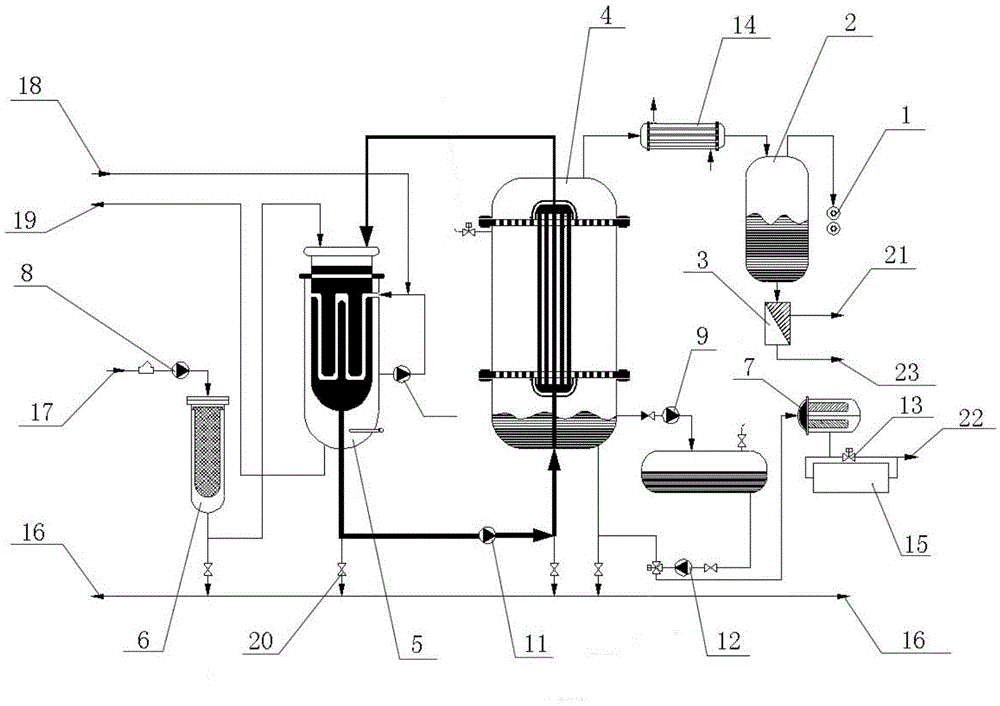

Image

Examples

Embodiment 2

[0061] Shanghai Zhongzhi Energy Technology Co., Ltd. is a subsidiary of a state-owned enterprise in Shanghai. The company has a business of selling "Cummins" generator sets as an agent and serving them for life. Equipment, including diesel reserves, the company has to start the machine for 30 minutes of maintenance every three months. The most difficult problem to deal with is that the diesel oil stored in iron drums for a long time contains oxidation and absorbs water. Oil drums (tank) The rusted iron filings particles pollute the diesel oil and cause the diesel oil to become turbid and dark in color, so it can no longer be used. Costs are reduced and energy is saved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com