A method of recycling waste asphalt

A technology for waste asphalt and recycled asphalt, applied in the field of waste asphalt regeneration, can solve the problems of long working hours and complicated operation steps, and achieve the effect of increasing the flash point and avoiding harmful gases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

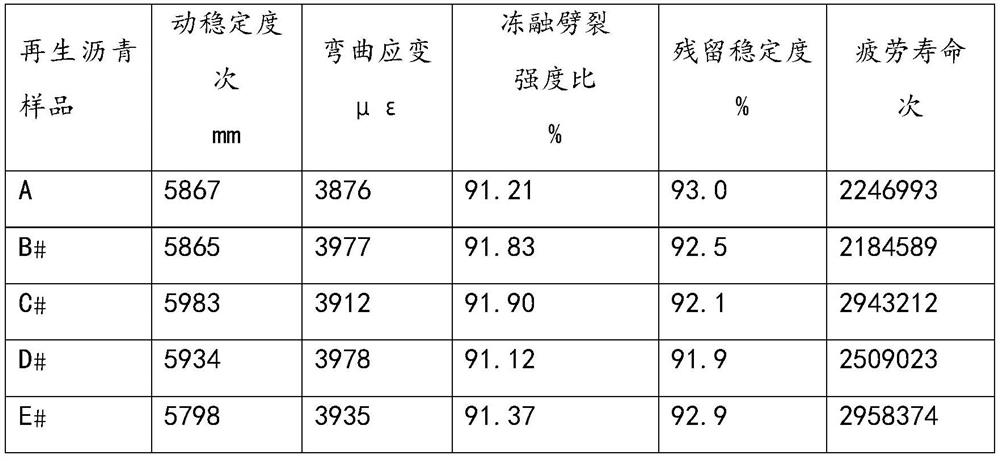

Examples

Embodiment 1

[0037] A kind of asphalt regeneration method, the regeneration additive used is composed of, calculated in parts by weight:

[0038] Naphthenic oil 60%

[0039] Petroleum resin 30%

[0040] Ethyl Acrylate 2%

[0041] Methyl methacrylate 4%

[0042] Cellulose 2%

[0043] Styrene 2%.

[0044] Concrete asphalt regeneration method comprises the following steps:

[0045] The waste asphalt is milled from the road surface, crushed and screened,

[0046] Mix waste asphalt aggregates, fillers, asphalt emulsifiers, recycled asphalt additives, and stir and mix,

[0047] Compact the mixture described in the previous step;

[0048] The composition of the mixture comprises: 70% (weight) of waste asphalt, 23% (weight) of aggregate, 2% (weight) of filler, 1% (weight) of asphalt emulsifier, and 4% (weight) of recycled asphalt additive.

[0049] Portland cement is selected as aggregate; limestone is selected as filler; quaternary ammonium salt emulsifier is selected as asphalt emulsifie...

Embodiment 2

[0052] A kind of asphalt regeneration method, the regeneration additive used is composed of, calculated in parts by weight:

[0053] Naphthenic oil 70%

[0054] Petroleum resin 20%

[0055] Ethyl Acrylate 3%

[0056] Methyl methacrylate 3%

[0057] Cellulose 1%

[0058] Styrene 3%

[0059] Concrete asphalt regeneration method comprises the following steps:

[0060] The waste asphalt is milled from the road surface, crushed and screened,

[0061] Mix waste asphalt aggregates, fillers, asphalt emulsifiers, recycled asphalt additives, stir and mix, and compact the mixture described in the previous step;

[0062] The composition of the mixture includes: 60% (weight) of waste asphalt, 30% (weight) of aggregate, 2% (weight) of filler, 5% (weight) of asphalt emulsifier, and 3% (weight) of recycled asphalt additive.

[0063] Portland cement and steelmaking slag are selected as aggregates; slaked lime is selected as filler; alkylamide polyamine asphalt emulsifier is selected as ...

Embodiment 3

[0066] A kind of asphalt regeneration method, the regeneration additive used is composed of, calculated in parts by weight:

[0067]Naphthenic oil 60%

[0068] Petroleum resin 20%

[0069] Ethyl Acrylate 5%

[0070] Methyl methacrylate 5%

[0071] Cellulose 5%

[0072] Styrene 5%.

[0073] Concrete asphalt regeneration method comprises the following steps:

[0074] The waste asphalt is milled from the road surface, crushed and screened,

[0075] Mix waste asphalt aggregates, fillers, asphalt emulsifiers, recycled asphalt additives, stir and mix, and compact the mixture described in the previous step;

[0076] The composition of the mixture comprises: 65% (weight) of waste asphalt, 30% (weight) of aggregate, 2% (weight) of filler, 1% (weight) of asphalt emulsifier, and 2% (weight) of recycled asphalt additive.

[0077] Portland cement or steelmaking slag is used as aggregate; fly ash is selected as filler; quaternary ammonium salt emulsifier is selected as asphalt emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com