Active mineral waste residue powder production system and technological process thereof

A production system and technology for slag powder, applied in the field of non-metallic building materials, to achieve the effects of accelerating the reaction speed, increasing the contact area, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0032] At the same time, it should be pointed out that all the connecting lines in the drawings are only schematic representations. In practice, they can represent specific pipeline connections, fluid connections or electrical connections. It is the disclosed content of the present invention.

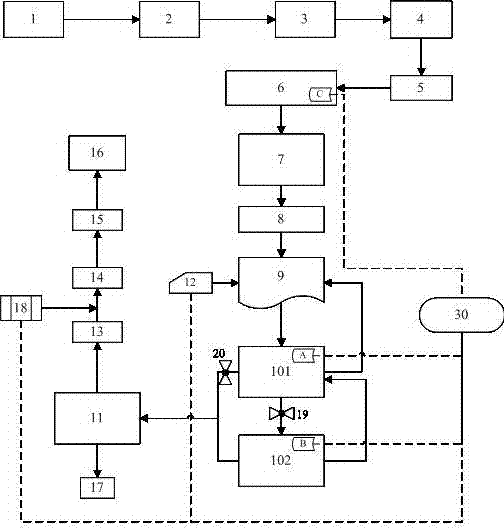

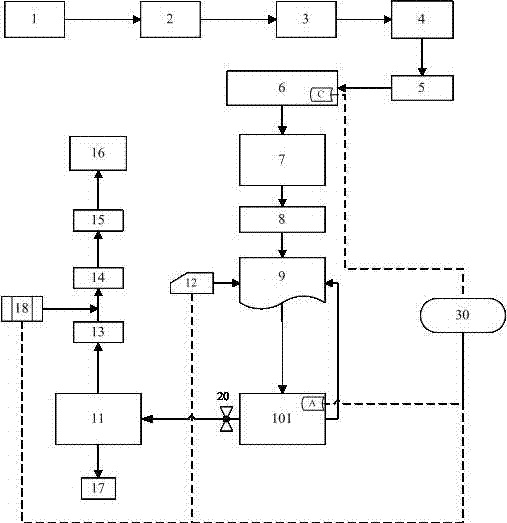

[0033] Such as figure 2 As shown, the active slag powder production system of the present invention mainly includes a slag powder stockyard 1, a loader 2 for transporting slag to a slag bin 3, a primary drying device 4 for primary drying of the slag, and a primary drying device 4 connected to the primary The primary iron remover 5 at the rear end of the drying device 4 transports the pretreated slag to the belt conveyor 6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com