Dry cutting method for dry ice cooling

A dry cutting and dry ice technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of high economic cost, pollution and troublesome follow-up treatment, to improve productivity, improve service life, The effect of reducing the content of O2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

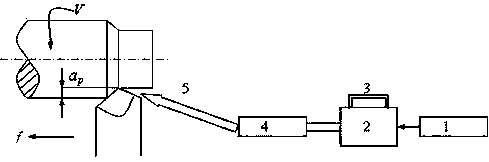

[0018] (1) When the pulverizer 2 and the air compressor 1 are all closed, open the top cover 3, load industrial dry ice, close the top cover, open the pulverizer 2, make the dry ice evenly crushed for 3~5 minutes, and turn on the air compressor 1. Adjust the powder flow valve 4 to a flow rate of 20~40kg / h, the distance between the nozzle and the cutting part is 15cm, and the cooling is performed from the flank surface, and the diameter of the nozzle is 2cm.

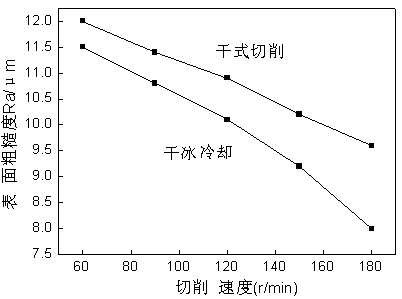

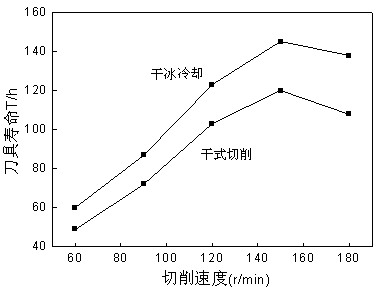

[0019] (2) Take YT15 tool turning 45 steel (HRC=58) ф200 outer circle as an example to verify the effect of dry ice cooling, tool parameters: gamma 0 =7°, K γ =90°, lambda s =0; cutting parameters: cutting speed is 60, 90, 120, 150, 180r / min, feed rate is 0.08mm / r, cutting depth a p =1mm, under the condition that the amount of dry ice is 40kg / h, use the JB-1C roughness detector to measure the surface roughness value of the workpiece R a (μm), and use the JT1168 tool sharpness and edge retention tester to measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com