Method for producing multielement nitro-compound fertilizer

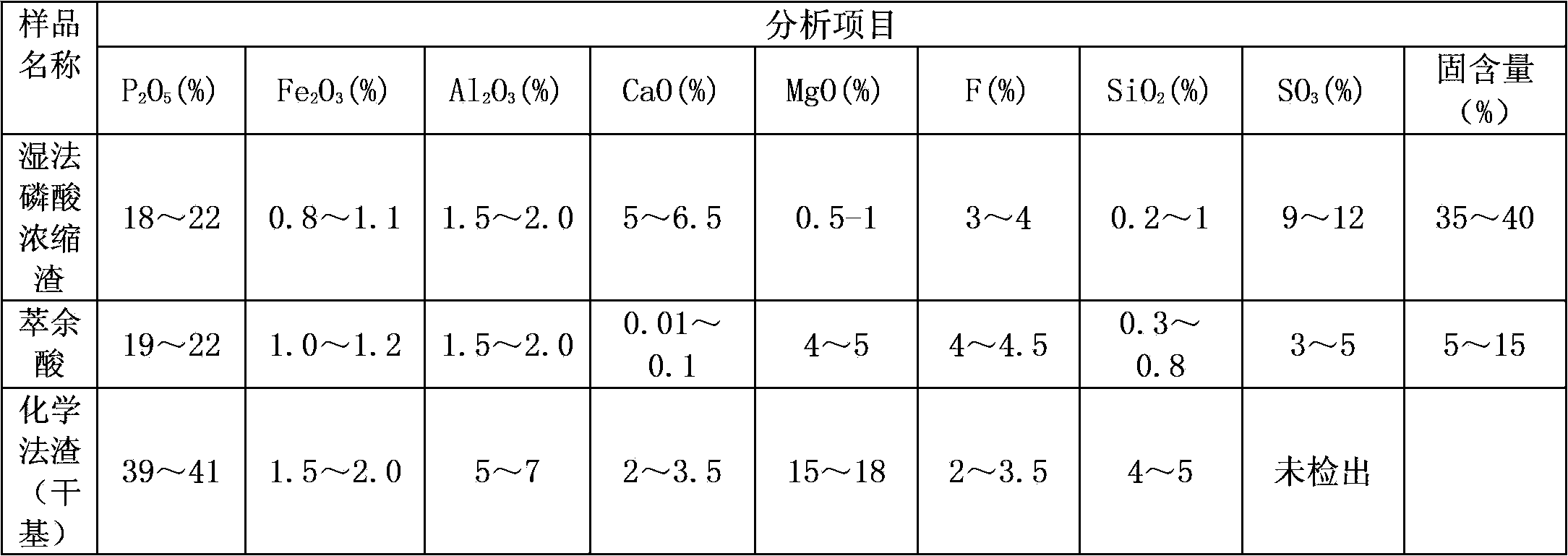

The technology of a kind of nitro compound fertilizer and its production method is applied in the production field of multi-element nitro compound fertilizer, which can solve problems such as the inability to handle raffinate acid, chemical process slag, and difficult nutrition of monoammonium phosphate, so as to achieve low cost and promote The effect of growth and development and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100 grams of wet process phosphoric acid concentrated sludge, 120 grams of chemical process slag, 105 grams of raffinate acid, 70 grams of potassium sulfate, and 20 grams of borax, stir evenly, add 300 grams of nitric acid (65-68%) to react for 3 minutes, and pass ammonia The neutralization reaction is carried out with gas, and the neutralization degree is adjusted to 1.15, and then dried at 100°C. A qualified product is obtained: the effective content (weight percentage) of the product is 40.47%, of which the nitrate nitrogen content is 7.07%, the ammonia nitrogen content is 13.43%, the phosphorus pentoxide content is 14.26%, and the potassium oxide content is 5.71%. It also contains 1.60% calcium oxide, 4.20% magnesium oxide, 1.06% silicon oxide, 0.75% iron oxide, and 0.34% boron.

Embodiment 2

[0029] Take 100 grams of wet-process phosphoric acid concentrated sludge, 130 grams of chemical process slag, 110 grams of raffinate acid, 80 grams of potassium sulfate, and 20 grams of borax, stir well, add 310 grams of nitric acid (65-68%) and react for 3 minutes, and pass ammonia The neutralization reaction is carried out with gas, and the neutralization degree is adjusted to 1.15, and then dried at 100°C. A qualified product is obtained: the effective content (weight percentage) of the product is 40.63%, of which the nitrate nitrogen content is 7.02%, the ammonia nitrogen content is 12.90%, the phosphorus pentoxide content is 14.43%, and the potassium oxide content is 6.28%. It also contains 1.57% calcium oxide, 4.28% magnesium oxide, 1.10% silicon oxide, 0.75% iron oxide and 0.33% boron.

Embodiment 3

[0031] Take 110 grams of wet process phosphoric acid concentrated sludge, 140 grams of chemical process slag, 120 grams of raffinate acid, 100 grams of potassium sulfate, and 30 grams of borax, stir evenly, add 350 grams of nitric acid (65-68%) and react for 3 minutes, and pass ammonia The neutralization reaction is carried out with gas, the neutralization degree is adjusted to 1.20, and then dried at 100°C. A qualified product is obtained: the effective content (weight percentage) of the product is 40.13%, of which the nitrate nitrogen content is 7.10%, the ammonia nitrogen content is 12.00%, the phosphorus pentoxide content is 14.01%, and the potassium oxide content is 7.02%. It also contains 1.53% calcium oxide, 4.14% magnesium oxide, 1.05% silicon oxide, 0.73% iron oxide, and 0.44% boron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com