System and method for zero discharge of magnesium oxide method desulfurization wastewater

A technology for desulfurization wastewater and magnesium oxide, applied in chemical instruments and methods, separation methods, magnesium sulfate and other directions, can solve the problems of incomplete recovery and low product output value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

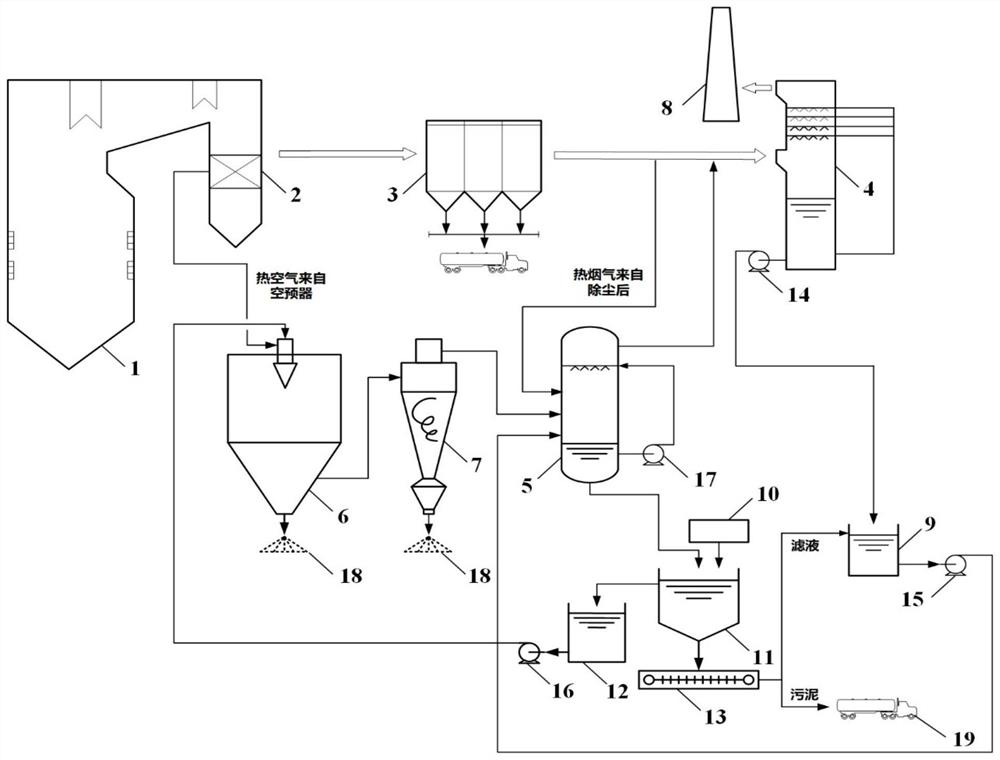

Embodiment 1

[0034] Taking the desulfurization wastewater treatment capacity of 2000kg / h as an example, the magnesium sulfate mass concentration therein is 10%. The temperature is 125~130℃, and the flue gas volume at 140℃ entering the thermal method reduction device is 22000m 3 / h, after concentrating, waste water reduction is 660kg / h, and flue gas is cooled to 50 ℃, when the mass concentration of magnesium sulfate solution reaches 30% in thermal method decrementing device (5), after waste water enters sedimentation tank (11), add Diatomaceous earth produces precipitation, wherein: the thermal method reduction device (5) adopts an empty tower spray structure, and the upper part of the tower is equipped with a spray device, and the nozzle adopts a spiral type, so that the atomized particle size of the wastewater is less than 500 μm; A circulating pump (17) is arranged outside the metering device (5), and the circulating pump (17) can spray the magnesium desulfurization wastewater back and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com