Preparation method of self-cleaning wool fabric

A self-cleaning, wool-based technology, applied in the field of preparation of self-cleaning wool fabrics, can solve problems such as skin damage, and achieve the effects of enhancing bonding fastness, improving self-cleaning efficiency, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of self-cleaning wool fabric, the specific steps are:

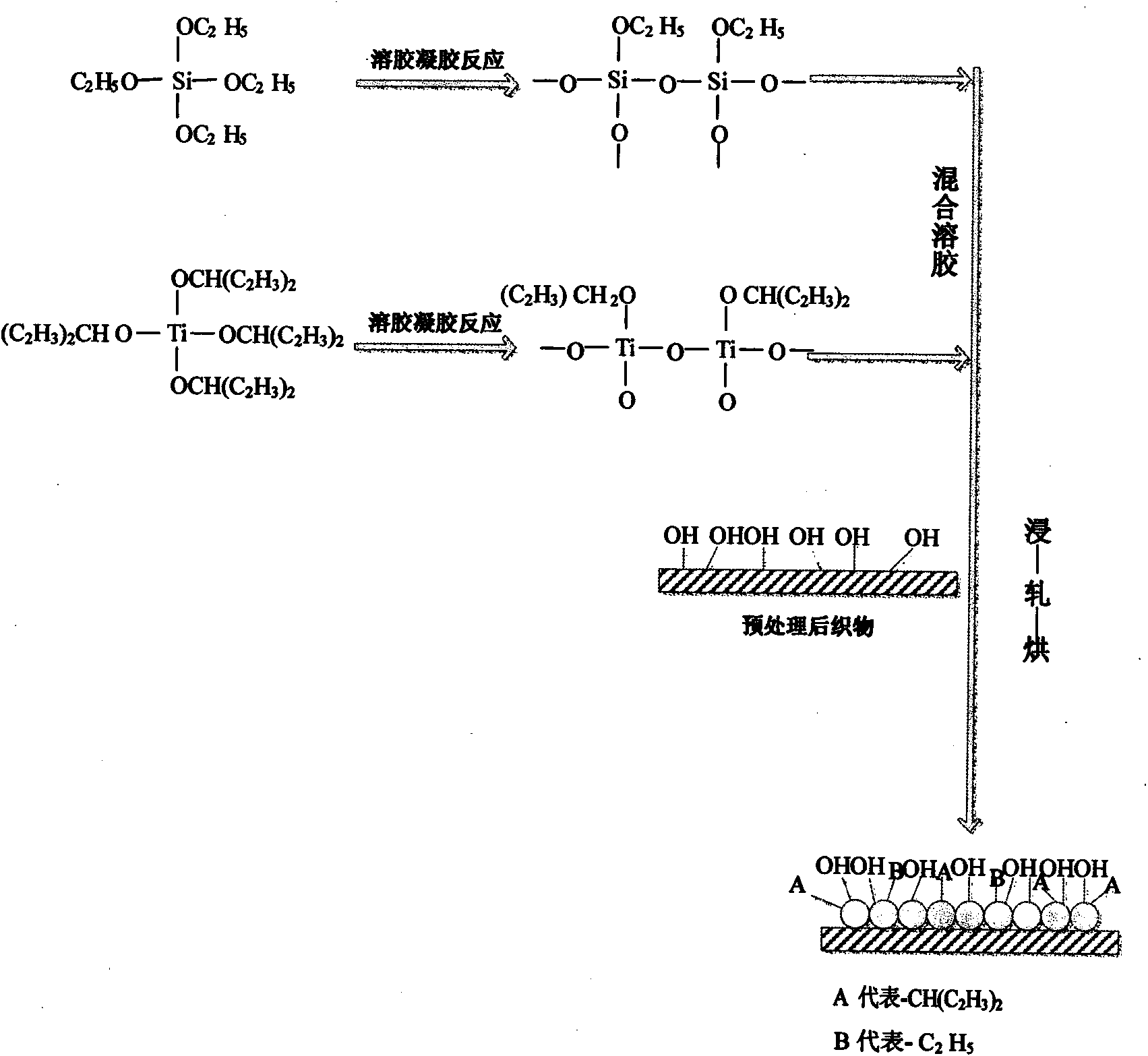

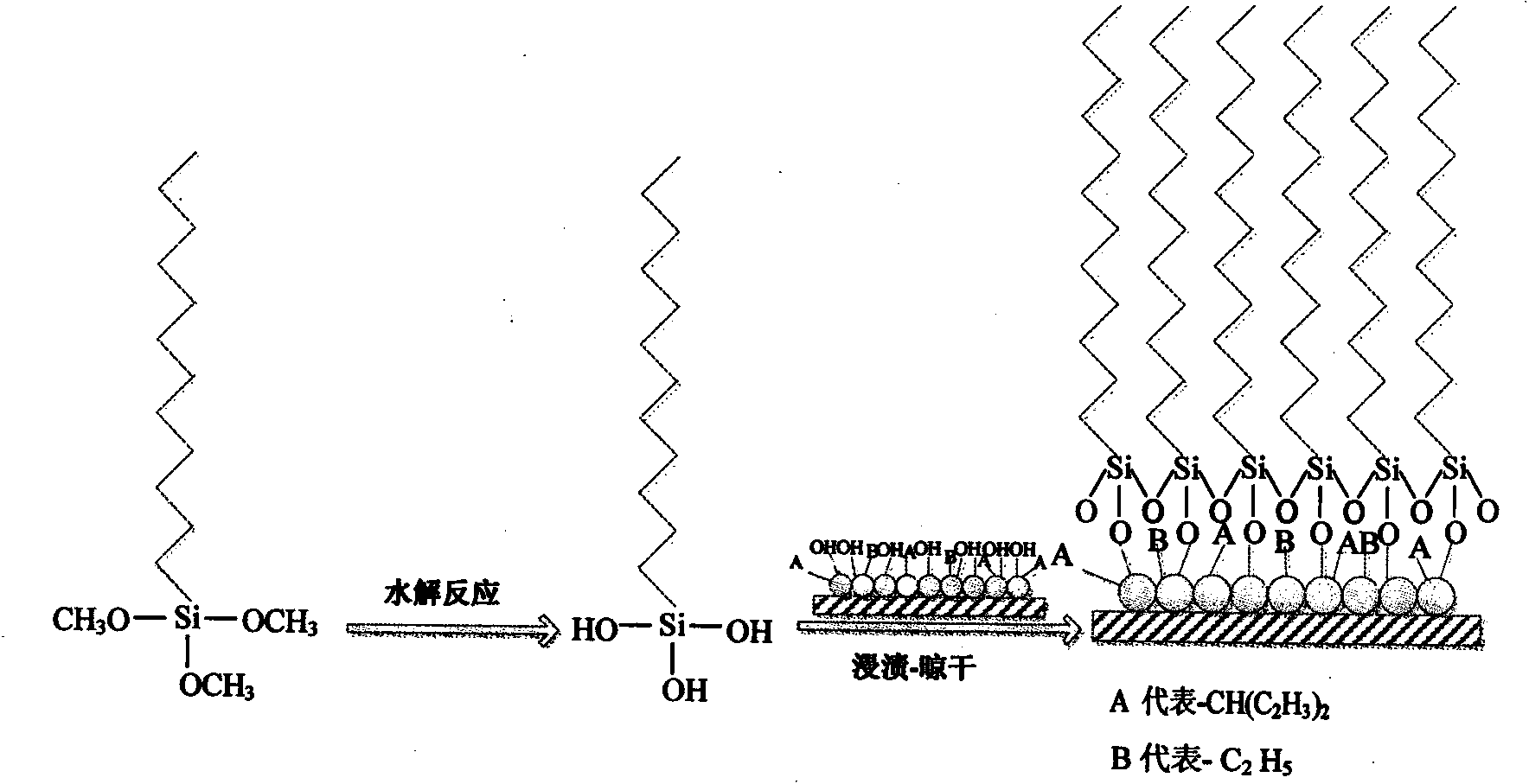

[0036] (1) Preparation of TiO 2 / SiO 2 Mixed sol:

[0037] like figure 1 As shown, mix 8ml of tetraisopropyl titanate with a mass fraction of 97%, 4ml of diethanolamine and 24ml of absolute ethanol, stir at room temperature at a stirring speed of 800rmp for 1 hour, and then add 14ml of The volume fraction is 75% alcohol, stirred at room temperature for 1 hour to form a stable and transparent TiO 2 Sol; its concrete reaction is as follows:

[0038] 1) Hydrolysis reaction

[0039] Ti{OCH(C 2 h 3 ) 2} 4 +nH 2 O→Ti{OCH(C 2 h 3 ) 2} 4-n (OH) n +n(C 2 h 3 ) 2 CHOH(n=1,2,3,4)

[0040] 2) Polymerization reaction

[0041] {(C 2 h 3 ) 2 CHO} 3 Ti-OH+HO-Ti{OCH(C 2 h 3 ) 2} 3 →H 2 O+

[0042] {(C 2 h 3 ) 2 CHO} 3 Ti-O-Ti{OCH(C 2 h 3 ) 2} 3

[0043] {(C 2 h 3 ) 2 CHO} 3 Ti-OCH(C 2 h 3 ) 2 +HO-Ti{OCH(C 2 h 3 ) 2} 3 →

[0044] {(C 2 h 3 ) 2 CHO} 3 Ti-O-Ti{O...

Embodiment 2

[0061] (1) Preparation of TiO 2 / SiO 2 mixed sol

[0062] Mix 8ml of tetraisopropyl titanate with a mass fraction of 95%, 1.6ml of diethanolamine and 36ml of absolute ethanol and stir at room temperature at a stirring speed of 800rmp for one hour, and then add 14ml of 75% alcohol, stirred at room temperature for 1 hour to form a stable and transparent TiO 2 Sol; 4ml of concentrated ammonia water with a mass fraction of 28%, 25ml of ethanol, and 1.5ml of deionized water were mixed at room temperature at a stirring speed of 1100rmp for one hour, then quickly added a mixed solution of 2.25ml of tetraethyl orthosilicate and 25ml of ethanol, After 1 min, reduce the stirring speed to 400rmp, and continue the reaction at room temperature for 2 hours to form SiO 2 Sol; the TiO obtained by the above steps 2 Sol and SiO 2 Sol, according to the Ti / Si molar ratio of 3:7, mixed and stirred for 1 hour to obtain TiO 2 / SiO 2 Mixed sol.

[0063] (2) wool pretreatment

[0064] Will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com