Environment-friendly-type water cycle automatic cleaning, lampblack discharging and purifying integrated machine

A technology of automatic cleaning and water circulation, applied in the direction of oil fume removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of troublesome replacement of filter screens, large system resistance, high cost, etc., and achieve small kitchen space occupied by installation and equipment technology Simple, highly recyclable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

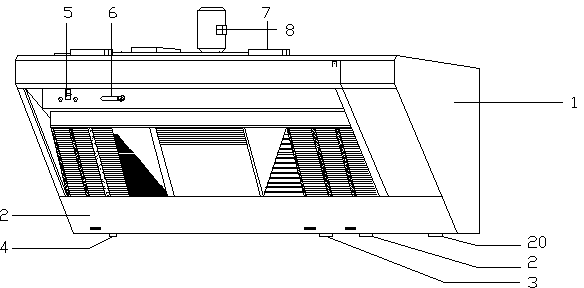

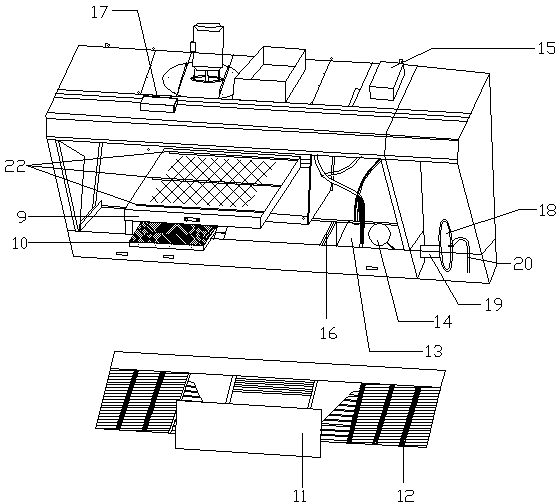

[0047] It includes a smoke exhaust hood shell 1, a water tank 2 installed in the lower part of the shell, an electrical console 6 arranged in the upper part of the cover, and a filter 11 is installed below the middle part where the inside of the smoke exhaust hood shell 1 is connected to the air outlet 8 Connect the air outlet 8 with the installation deflector 10, the centrifugal fan 9 is connected with the air outlet 8, and a water mist collision nozzle 22 is installed at the entrance of the centrifugal fan 8. Water tank 2 is provided with sewage outlet 3, overflow port 4, water inlet 5, and water inlet 5 connects floating ball valve switch 15, so that water tank 2 can replenish water automatically, water pump 14 is housed below water tank 2, and the water outlet of water pump 14 and The water mist collision nozzle 22 is connected. A maintenance door 12 and a front door panel 13 for easy disassembly are installed on the housing. An oil suction turntable 18 is installed at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com