Nanometer electromechanical vector hydrophone suitable for deep water

A vector hydrophone and nano-electromechanical technology, applied in the direction of using electric devices, using electromagnetic means, radio wave measurement systems, etc., can solve the problems of easy leakage of silicone oil, damage of vector hydrophones, difficulty in resisting high hydrostatic pressure, etc. , to achieve the effects of enhanced resistance to high hydrostatic pressure, reasonable design of pressure-resistant structure, and easy fabrication and assembly

Active Publication Date: 2014-05-21

ZHONGBEI UNIV

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the technology of MEMS hydrophones has become mature, but the polyurethane sound-permeable cap is too thick to cause deformation and rupture due to high pressure, and the silicone oil in the polyurethane sound-permeable cap is easy to leak out, and the air bubbles in the silicone oil and the sensitive head are drawn out The wire leads to poor sealing, which seriously affects the high-pressure performance of the MEMS vector sensor in the deep sea detection environment, and even destroys the hydrophone. The hydrostatic pressure resistance technology and environmental adaptability technology of the MEMS vector hydrophone are two key technologies. The material, air bubbles, and circuit lead holes of the sound cap are a major problem in the stability and sealing of the entire MEMS vector hydrophone. essential when applying

For example, the "micro-electromechanical vector hydrophone" disclosed in the Chinese invention patent No. 200910073993.4, this MEMS vector hydrophone is currently the best MEMS vector hydrophone with pressure resistance, but this vector hydrophone will still be used in deep water. The environment suffers a certain degree of damage, so that the pressure resistance performance of the existing hydrophone cannot meet the deep water conditions

The pressure upper limit of this MEMS vector hydrophone is 2Mpa. If it is necessary to improve the pressure resistance performance, it is necessary to solve the problem that the silicone oil in the polyurethane sound-permeable cap of the MEMS vector hydrophone is easy to leak, the sensitive head leads out the wires, and the seal is not good, etc. Defects that make hydrophones difficult to withstand high hydrostatic pressure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

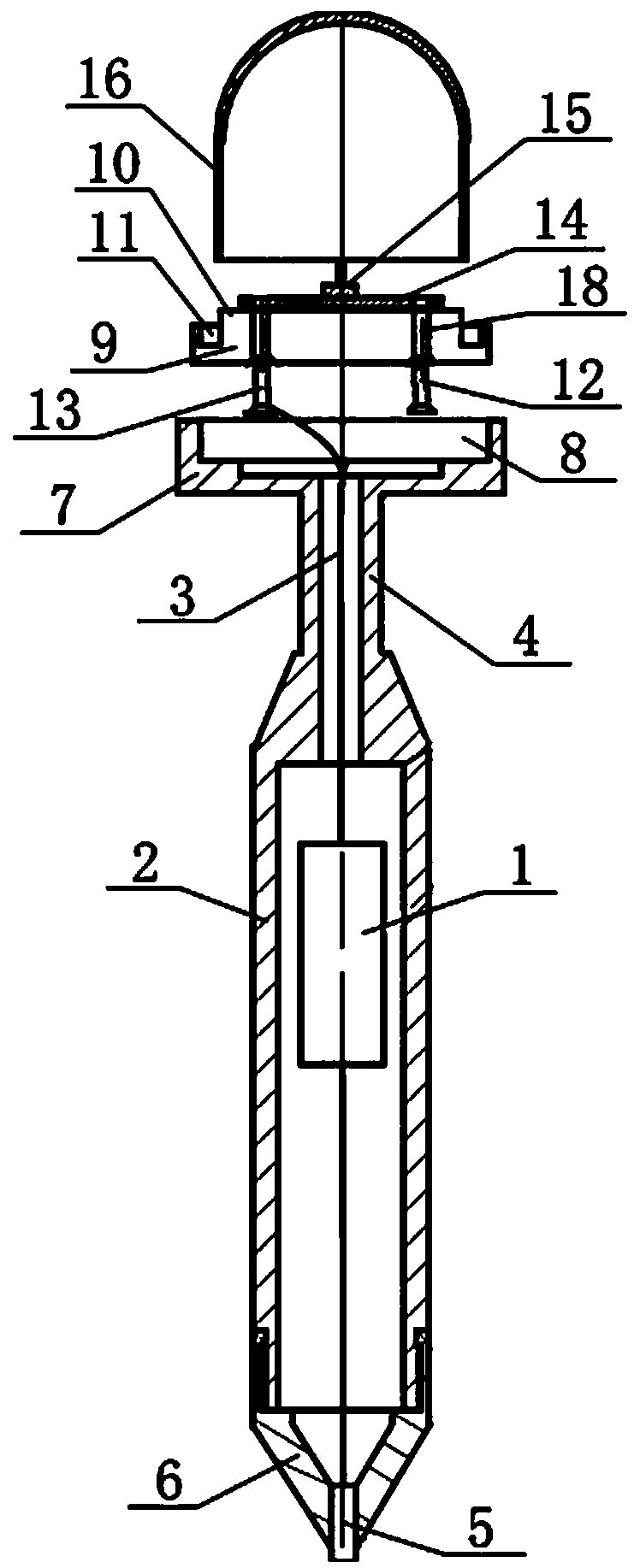

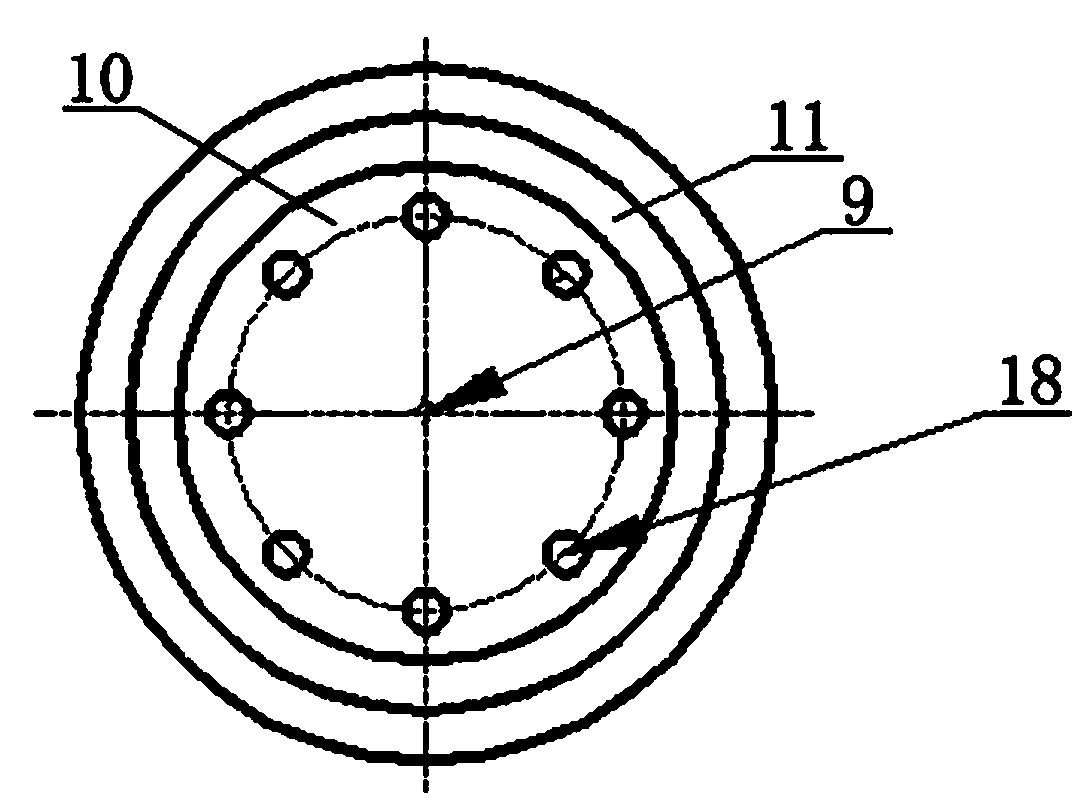

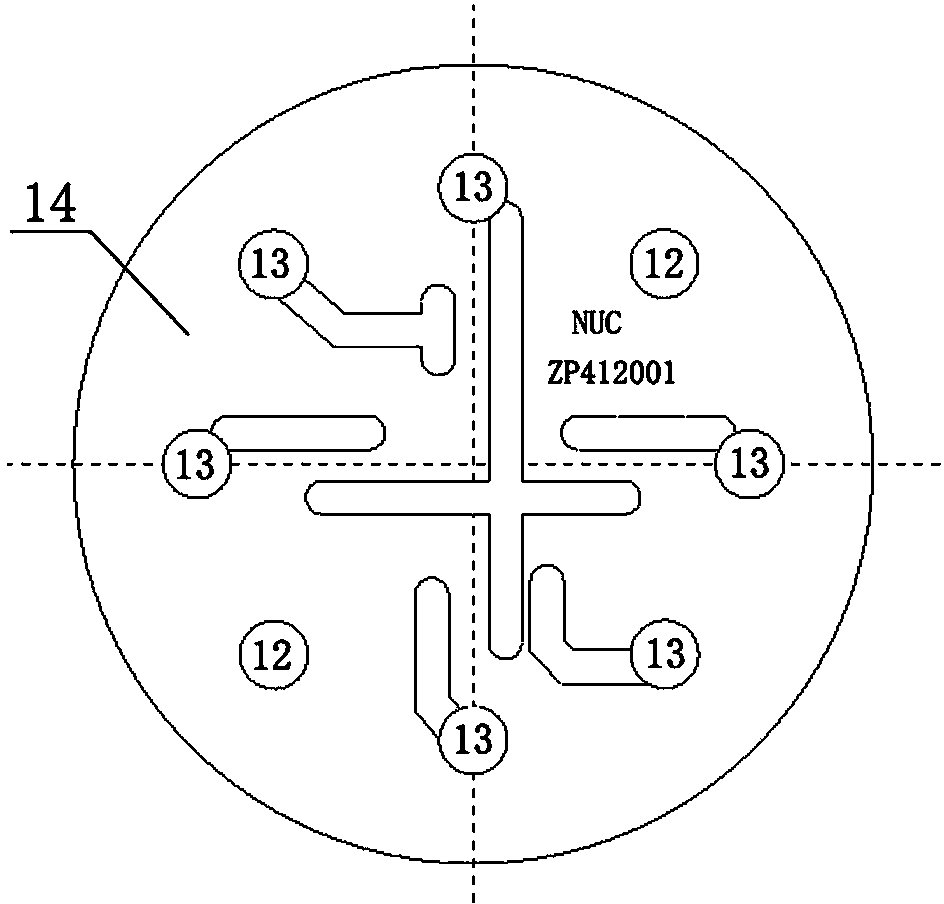

The invention discloses a nanometer electromechanical vector hydrophone suitable for deep water. The nanometer electromechanical vector hydrophone further improves the sealing property, the high hydrostatic pressure resistance, the environmental suitability, the reliability and the similar indexes of an MEMS vector hydrophone. The nanometer electromechanical vector hydrophone comprises a stainless steel circuit tube shell, a necking tube shell, a fixed disc and an insulated annular tray, wherein the insulated annular tray is provided with a lug boss, the lug boss is provided with a round PCB board and a detecting chip, the insulated annular tray is formed with a sealing screw hole and a signal screw hole and is firmly connected with an acoustic cap, the acoustic cap is filled with silicon oil and antifoaming agent, and a support frame is arranged in the acoustic cap. The nanometer electromechanical vector hydrophone prevents the acoustic cap from deformation under high pressure and bubbles, enables the acoustic cap to be resistant to high hydrostatic pressure, and improves the environmental suitability, the underwater sound signal testing reliability, practicability, stability and so on. Under the high pressure, the internal pressure and the external pressure of the acoustic cap are balanced so as to bear the high hydrostatic pressure; the hydrostatic pressure resistance test proves that the nanometer electromechanical vector hydrophone is capable of working normally under the hydraulic pressure more than or equal to 20 Mpa.

Description

technical field The invention relates to a vector hydrophone in the field of MEMS sensors, in particular to a nano-electromechanical vector hydrophone suitable for deep water with a superelastic material sound-permeable cap, no bubbles, and high hydrostatic pressure resistance. Background technique At present, vector hydrophones are used as sensors for measuring underwater acoustic signals. Communication and other fields have broad application prospects. The application of MEMS vector hydrophone has greatly improved the acquisition of underwater sound source signals. Due to the complexity of the deep water detection environment, the application effect of the MEMS vector hydrophone is closely related to many factors, among which the sealing and pressure resistance performance have an important influence on its application effect. At present, the technology of MEMS hydrophones has become mature, but the polyurethane sound-permeable cap is too thick to cause deformation and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01H11/00G01S7/521

Inventor 张国军刘源赵鹏申辉王续博郭静郭楠刘梦然简泽明张文栋

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com