GaN (gallium nitride)-based LED (light emitting diode) preparing method

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as affecting the light-emitting efficiency of LEDs, and achieve the effect of improving light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

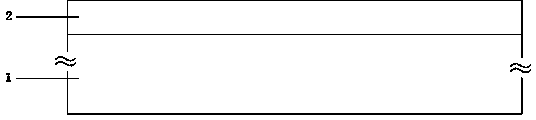

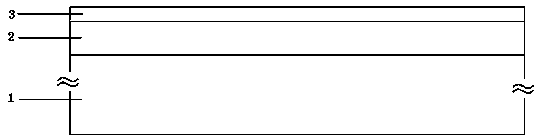

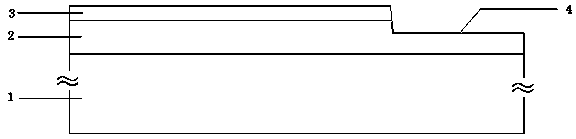

[0018] see Figure 1 to Figure 6 , Al is used as the dielectric film 6 material 2 o 3 For example, its refractive index is about 1.70, and the transparent conductive film 3 adopts ITO, and the steps of the preparation method of the present invention are:

[0019] An epitaxial GaN layer 2 is deposited on a sapphire substrate 1, wherein the epitaxial GaN layer 2 includes an N-GaN layer, an active layer, a P-GaN layer, and the like.

[0020] A transparent conductive film 3 is evaporated on the surface of the epitaxial gallium nitride layer 2 by using electron beam evaporation equipment.

[0021] Apply photoresist on the surface of the device, expose and develop, etch the N-type gallium nitride region and the scribe region 4 with ITO etchant, then use ICP equipment to etch the scribe region 4, remove the photoresist, and N at a moderately high temperature 2 Medium annealing.

[0022] According to the designed electrode pattern, glue is applied on the surface of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com