Thiacloprid and diafenthiuron containing insecticidal composition and application thereof

An insecticidal composition, thiacloprid technology, applied in the application, insecticide, biocide and other directions, can solve the problems such as compound preparation products that have not yet been seen, and achieve lowering the cost of medicine, lowering the dosage, and improving the insecticidal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

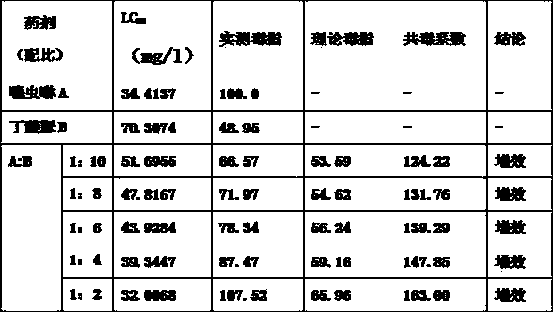

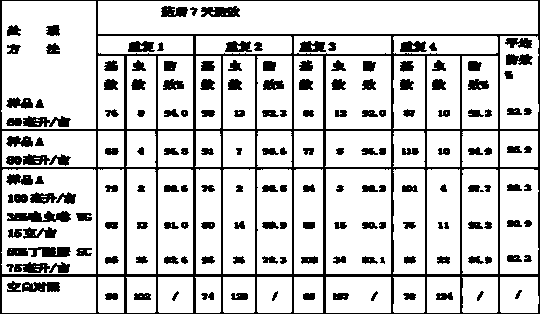

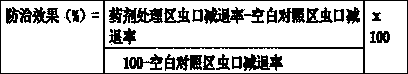

Method used

Image

Examples

Embodiment 1

[0025] Example 1 42% Thiacloprid Diafenthiuron Suspension Concentrate

[0026] The mass fraction ratio of each raw material is as follows: Thiacloprid technical (98%) 62KG, diafenthiuron technical (97%) 372KG, polycarboxylate compound 50KG, xanthan gum 2KG, magnesium aluminum silicate 5 KG, B Glycol 50 KG, silicone defoamer 3 KG, sodium benzoate 3 KG, water supplement. During production, put each raw material into the preparation kettle and stir for 30 minutes, make up the amount with water, sand mill for about 2 hours, defoam and adjust the pH value to obtain 42% thiacloprid diafenthiuron suspension concentrate.

Embodiment 2

[0027] Example 2 50% Thiacloprid Diafenthiuron Suspension Concentrate

[0028] The mass fraction ratio of each raw material is as follows: Thiacloprid technical (98%) 205 KG, diafenthiuron technical (97%) 431KG, polycarboxylate compound 50KG, fatty alcohol polyoxyethylene ether 10 KG, xanthan gum 2 KG, magnesium aluminum silicate 5 KG, ethylene glycol 50 KG, silicone defoamer 3 KG, sodium benzoate 3 KG, water to make up. During production, put each raw material into the preparation kettle and stir for 30 minutes, make up the amount with water, sand mill for about 2 hours, defoam and adjust the pH value to obtain 50% thiacloprid diafenthiuron suspension concentrate.

Embodiment 3

[0029] Example 3 30% thiacloprid diafenthiuron water dispersible granules

[0030] The mass fraction ratio of each raw material is as follows: Thiacloprid technical (98%) 103 KG, diafenthiuron technical (97%) 207 KG, modified terminal olefin sulfonate 10 KG, polycarboxylate 30 KG, anhydrous sodium sulfate 40 KG, starch 50 KG, kaolin supplement. During production, the raw materials are mixed and crushed by airflow crushing equipment, and the crushed intermediate is put into granulation and drying equipment, and made into granules according to the operation requirements of the equipment, and sieved after drying to obtain 30% thiacloprid · butyl ether Urea water dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com