Cefuroxime axetil composition and preparation method thereof

A cefuroxime axetil and composition technology, which is applied in the field of cefuroxime axetil composition and its preparation, can solve the problems of destroying the integrity of the drug package and not effectively covering the bitter taste of the drug, and achieve high bioavailability of the drug. The effect of short time and uniform drug content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

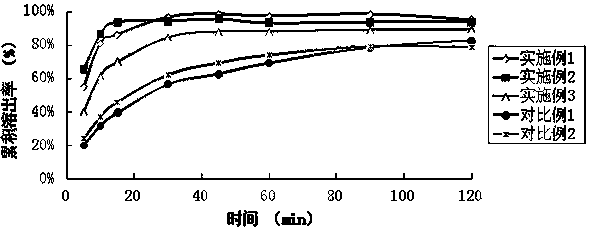

Examples

Embodiment 1

[0030] Example 1 Preparation of cefuroxime axetil composition and its dry suspension (based on 1000 parts, each containing 0.125 g of cefuroxime)

[0031] Element Dosage (g) Cefuroxime axetil (calculated as cefuroxime) 125 stearic acid 500 Sucrose stearate 33

[0032] (1) Preparation of the cefuroxime axetil composition: Heat and melt stearic acid and sucrose stearate in the prescribed amount in the above table, mix well, add cefuroxime axetil in the prescribed amount, mix evenly, and atomize The pressure is 0.18~0.24bar, and the inlet air temperature is -4~1℃ for spray granulation.

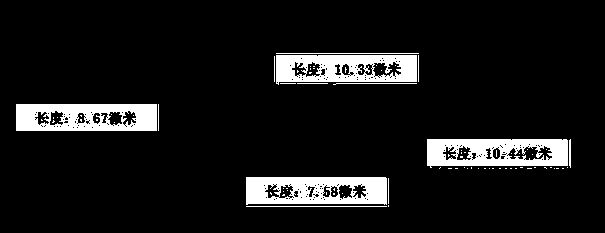

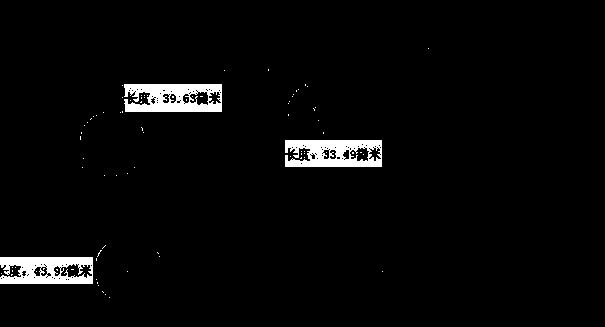

[0033] The micrograph (10×10 times) of raw material cefuroxime axetil is as figure 1 And the cefuroxime axetil composition particle diameter micrograph (10 * 10 times) that the present embodiment makes is as figure 2 shown. From figure 1 It can be seen that the particle size of cefuroxime axetil particles is small, and its average particle size is 7.4um. ...

Embodiment 2

[0035] Example 2 Preparation of cefuroxime axetil composition and its dry suspension (based on 1000 parts, each containing 0.125 g of cefuroxime)

[0036] Element Dosage (g) Cefuroxime axetil (calculated as cefuroxime) 125 stearic acid 500 Sucrose stearate 69

[0037] (1) Preparation of the cefuroxime axetil composition: Heat and melt stearic acid and sucrose stearate in the prescribed amount in the above table, mix well, add cefuroxime axetil in the prescribed amount, mix evenly, and atomize The pressure is 0.2~0.24bar, and the inlet air temperature is -1~3℃ for spray granulation.

[0038] (2) Preparation of dry suspension of cefuroxime axetil composition: mix the cefuroxime axetil composition prepared in step (1) with 15g xanthan gum and 2960g sucrose evenly, granulate in a fluidized bed, dry, add 20g of blackcurrant essence, mixed evenly to obtain a dry suspension product.

Embodiment

[0039] Example 3 Preparation of cefuroxime axetil composition and its granules (based on 1000 parts, each containing 0.125 g of cefuroxime)

[0040] Element Dosage (g) Cefuroxime axetil (calculated as cefuroxime) 125 stearic acid 250 Glyceryl behenate 250 Sucrose Palmitate 15

[0041] (1) Preparation of the cefuroxime axetil composition: Heat and melt the stearic acid, glyceryl behenate and sucrose palmitate in the prescribed amount in the above table, mix well, add the prescribed amount of cefuroxime axetil, mix evenly Finally, spray granulation with the atomization pressure at 0.18~0.25bar and the inlet air temperature at -2~3°C.

[0042] (2) Preparation of cefuroxime axetil composition granules: mix the cefuroxime axetil composition prepared in step (1) with 15g xanthan gum and 2900g sucrose evenly, granulate in a fluidized bed, dry, add 20g black Gallon essence, mix evenly to get granule product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com