A polymer film material and a preparation method thereof

A polymer membrane, polymer technology, applied in the field of membrane materials, can solve the problems of affecting the detection results, blood cell destruction, activation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

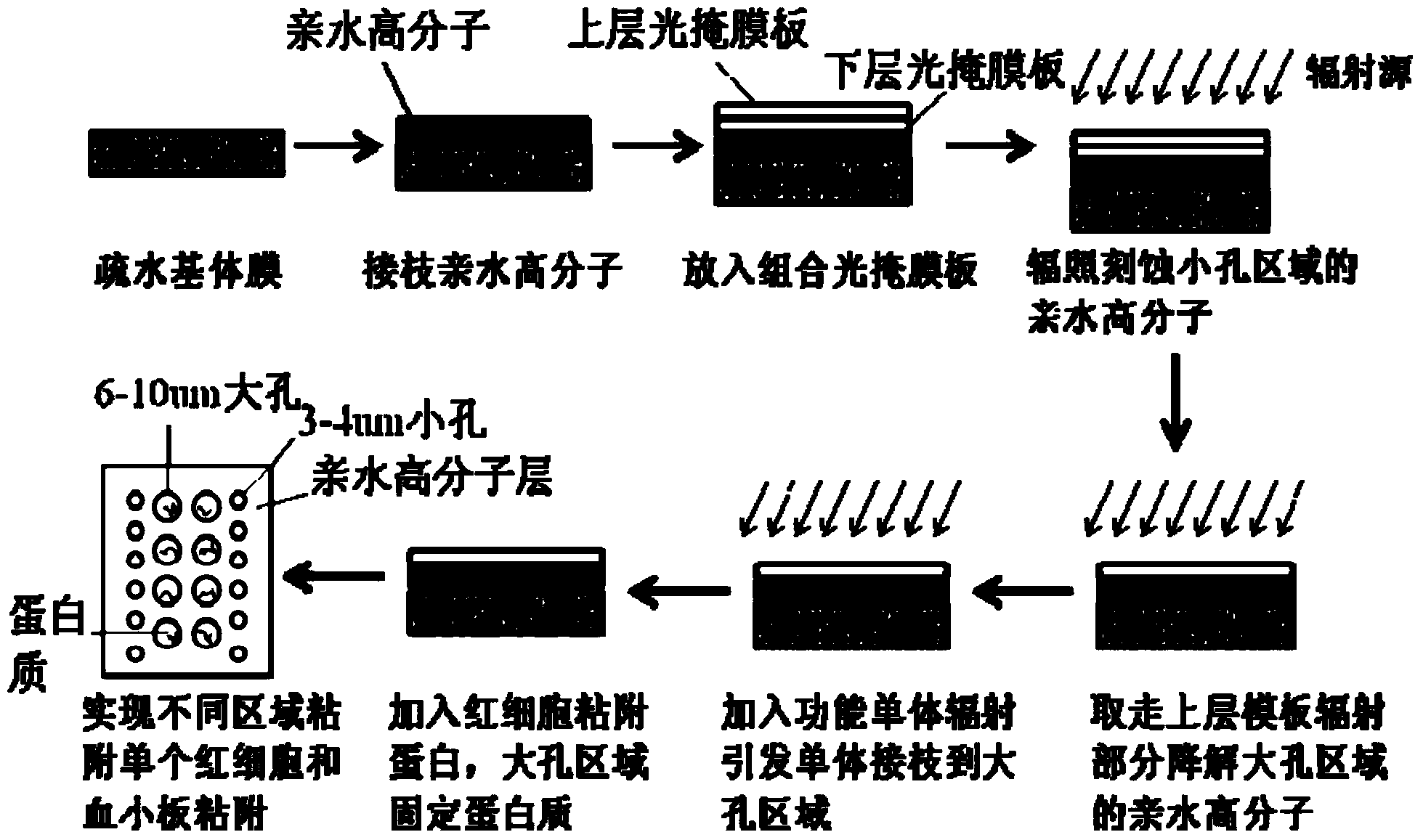

[0045] The present invention also provides a kind of preparation method of above-mentioned polymer film material, it is characterized in that, comprises the following steps:

[0046] A) Under the action of a photoinitiator, the hydrophilic substance is grafted on the surface of the hydrophobic polymer film to form a polymer film. The polymer film includes a hydrophobic polymer layer and is compounded on the hydrophobic polymer film. a hydrophilic polymer layer on the polymer layer;

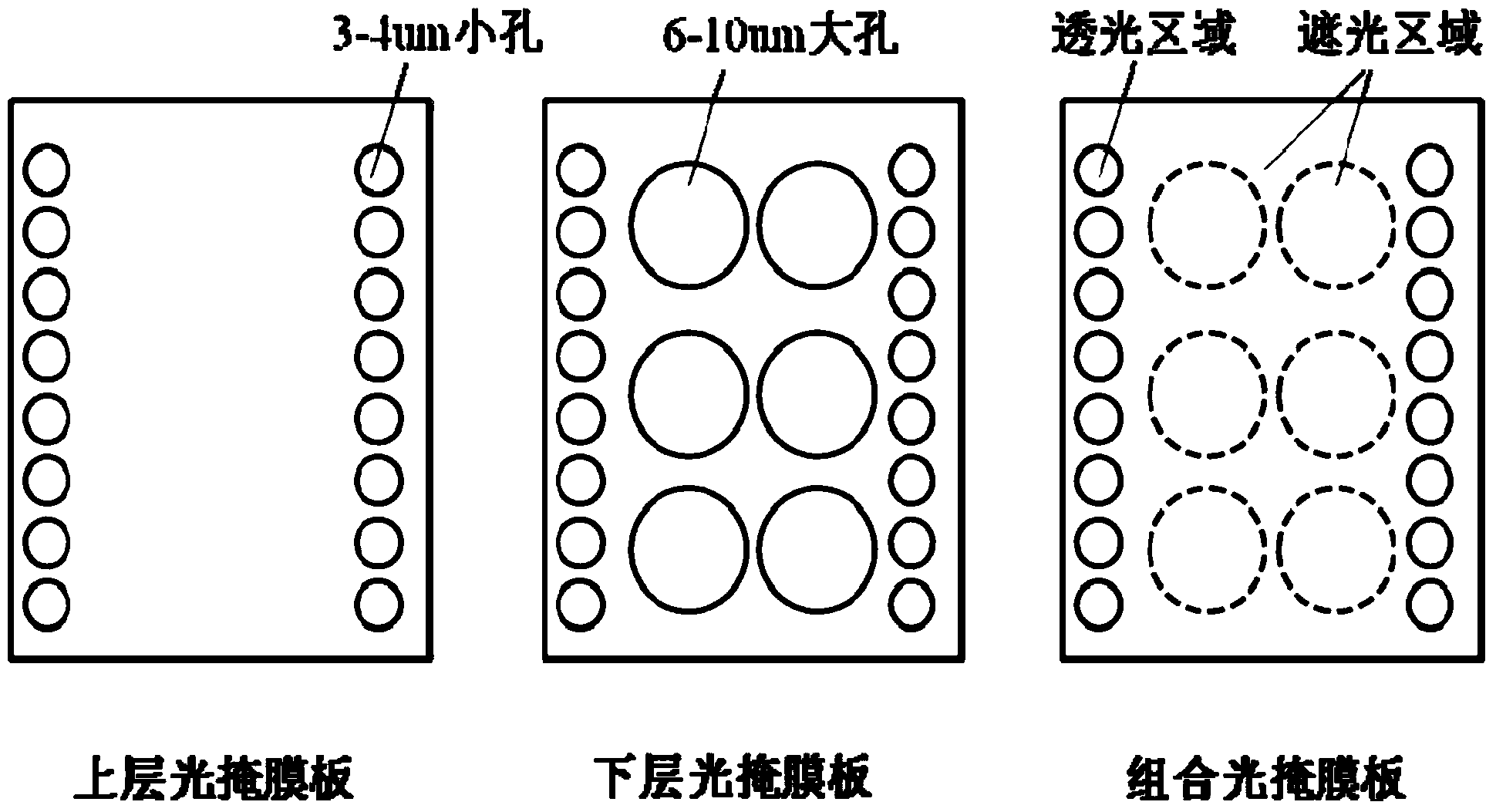

[0047] B) Under the action of a photomask, photolithography forms a through hole on the hydrophilic polymer layer of the polymer film, and forms a hydrophilic adhesive on the hydrophilic polymer layer of the polymer film. attached area;

[0048] C) adding functional monomers to the hydrophilic adhesion region under ultraviolet light irradiation to form functional substances, and then immobilizing fibronectin on the functional substances to obtain polymer membrane materials;

[0049] The hydrophi...

Embodiment 1

[0068] The hydrogenated styrene-butadiene-styrene terpolymer SEBS (produced by Kraton, USA, brand 1650) was used as the base material of the hydrophobic polymer film. First, the 5wt% chloroform solution was prepared by the drop film method with an area of 3*3cm 2 , a hydrophobic polymer film with a thickness of 100um, and then put the above-mentioned hydrophobic polymer film into the acetone solution of 2wt% benzophenone, soak for 30 minutes, and then place the film on a quartz plate, and put the hydrophilic 2-Methacryloyloxyethylphosphorylcholine (produced in Japan, sold by Nanjing Huizhe Trading Co., Ltd.) was prepared into a 20wt% aqueous solution, which was uniformly added dropwise to the surface of the above-mentioned hydrophobic polymer film. , the dropwise amount is 10mL. After being irradiated under an ultraviolet lamp for 1-3 minutes, rinsed with a large amount of PBS buffer solution to obtain a polymer film.

[0069] Prepare a combined stencil consisting of an up...

Embodiment 2

[0078] The hydrophobic polymer matrix material is changed, and the matrix material is made of polypropylene (PP) and prepared by blown film method. The remaining steps are carried out as described in Example 1.

[0079] The surface of the polymer membrane material after the above-mentioned blood adhesion is observed through an electron microscope, and the red blood cells and platelets have achieved single cell separation, forming red blood cell arrays and platelet arrays respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com