Pouring protecting device and pouring protecting control method for continuously cast ladle

A protection device and continuous casting technology, which is applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems that people cannot approach the sealing part, the operator cannot find it, and the secondary pollution of molten steel, etc., so as to prevent secondary pollution , Significant economic benefits, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

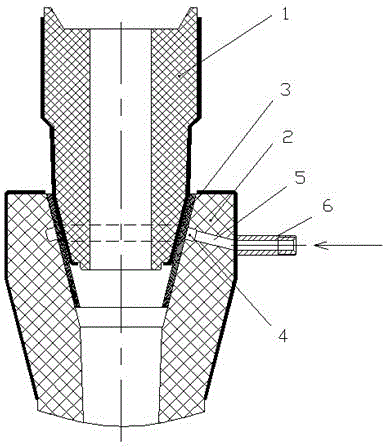

Image

Examples

Embodiment Construction

[0020] The protective pouring concept of the present invention is completely different from the existing conventional protective pouring concept.

[0021] The existing conventional protective pouring concept, regardless of whether the seal is effective or not, supplies argon in the external space of the sealed connection in a quantitative manner to form an argon mass protective atmosphere, which is effective when the seal is slightly damaged. Once the seal is damaged, the quantitative argon cannot meet the requirements. When the inhaled air volume is required, the inhaled air is supplemented, and the on-site operator cannot find out, causing substantial secondary pollution of molten steel.

[0022] The protection pouring concept of the present invention is to automatically compensate the argon gas supply to the automatic regulating valve through the PID controller according to the amount of gas volume demand at the sealed connection (set value 0.6Mpa), which belongs to the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com