Method for separating potassium oxide from potassium-containing sodium aluminate solution

A technology containing potassium sodium aluminate and potassium oxide, applied in the field of separation of potassium oxide, can solve the problems of high price, high separation cost, loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

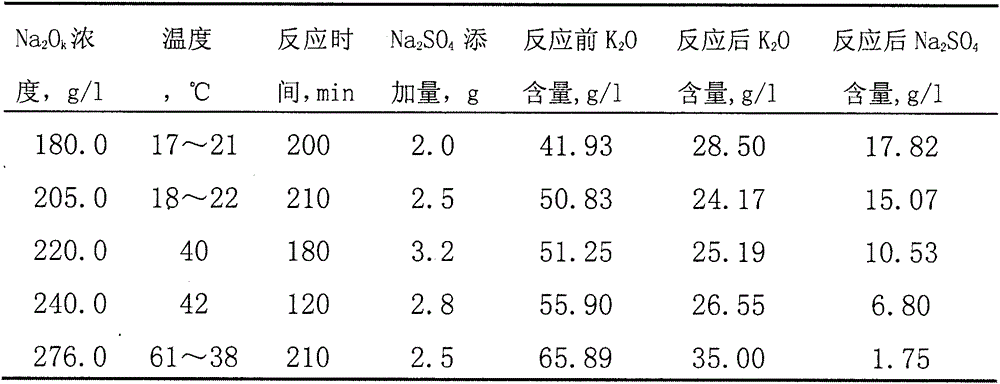

Embodiment 1

[0015] Evaporate the mother liquor by Bayer method and dilute to Na 2 0 k 180g / l, analysis k 2 O41.93g / l, Na 2 SO 4 2.11g / l, take 50ml mother liquor and add 2.0g analytical pure anhydrous Na 2 SO 4 , stirred and reacted for 200 minutes at room temperature between 17°C and 21°C, let it stand for 10 hours, and took the supernatant for analysis. 2 O28.50g / l, Na 2 SO 4 17.82g / l. Add analytical pure NaOH to 30ml clear liquid to Na 2 o k Up to 280g / l, plus 0.03g Na 2 SO 4 , stirred for 210 minutes, drip filtered, and analyzed Na in the filtrate 2 SO 4 1.74g / l.

Embodiment 2

[0017] Filter the Bayer process high-distillation mother liquor, and dilute the filtrate to Na 2 o k 220g / l, analysis k 2 O51.25g / l, Na 2 SO 4 2.13g / l, take 50ml mother liquor and add 3.2g analytical pure anhydrous Na 2 SO 4 , stirred the reaction at 40°C for 180 minutes, let it stand for 14 hours, and took the supernatant to analyze k 2 O25.19g / l, Na 2 SO 4 10.53g / l.

Embodiment 3

[0019] Filter the Bayer process high-distillation mother liquor and analyze Na 2 o k 276g / l, k 2 O65.89g / l, Na 2 SO 4 2.01g / l, take 50ml mother liquor and add 2.5g analytical pure anhydrous Na 2 SO 4 , stirred and reacted for 210 minutes under the condition of 61°C~38°C, drip filtered, and the filtrate was analyzed k 2 O35.00g / l, Na 2 SO 4 1.75g / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com