Photocatalytic electrode responding to visible lights and application thereof on chromium-containing wastewater treatment

A photocatalysis and visible light technology, applied in the field of advanced oxidation technology and water treatment, can solve the problem of high probability of photo-generated electrons and holes recombination, and achieve the effect of inhibiting electron-hole recombination, saving operating costs and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

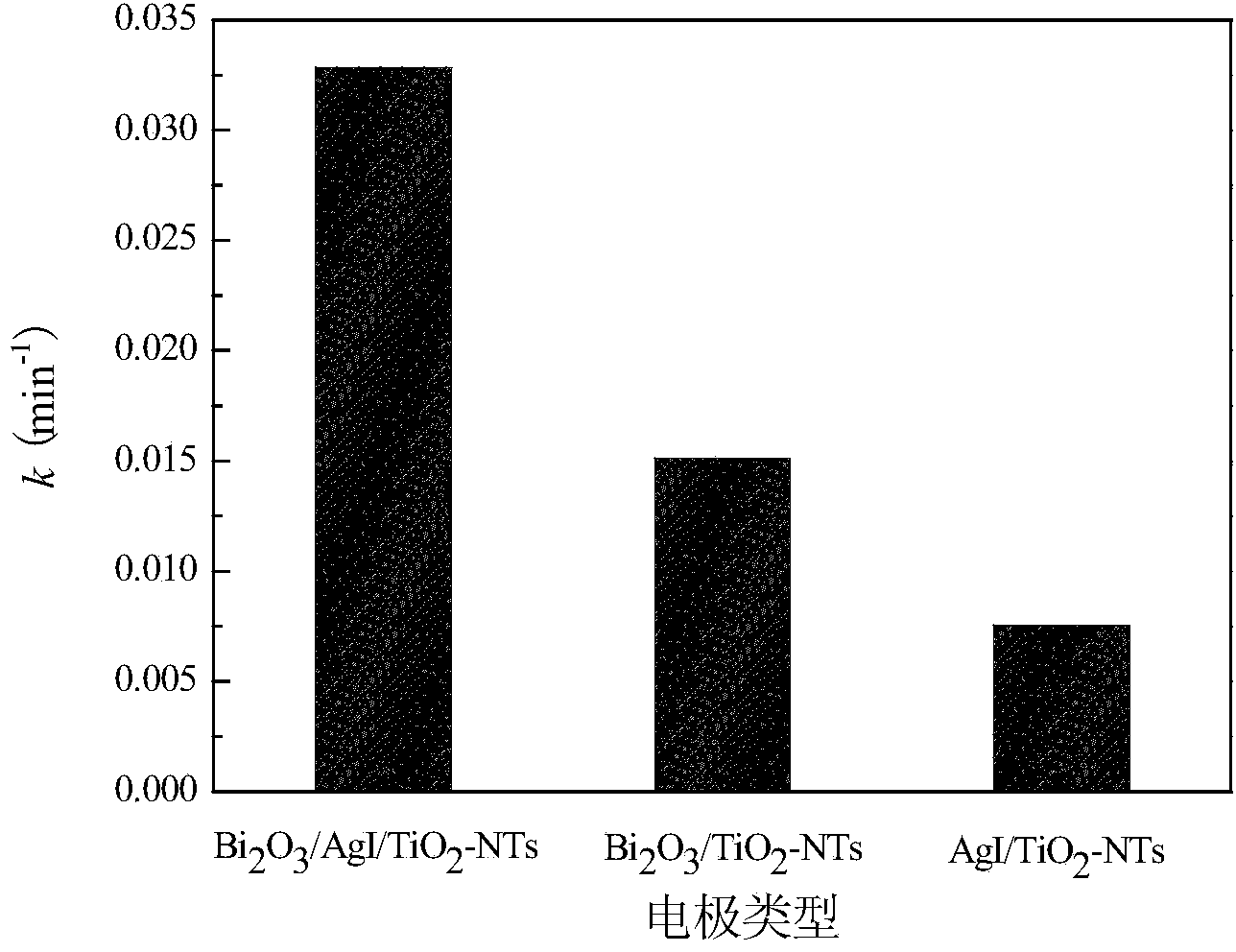

[0046] In AgI / TiO 2 Bi loading during the preparation of -NTs 2 o 3 , by comparing AgI / TiO 2 -NTs, Bi 2 o 3 / TiO 2 -NTs and Bi 2 o 3 / AgI / TiO 2 Hexavalent chromium removal rate constant of -NTs, investigation of AgI and Bi 2 o 3 Whether there is a synergistic effect.

[0047] From figure 1 It can be seen that under the applied bias voltage of 2V, using Bi 2 o 3 / AgI / TiO 2 - The removal rate constant of hexavalent chromium in the reactor of the NTs electrode is significantly higher than that of AgI / TiO 2 -NTs and Bi 2 o 3 / TiO 2 - The sum of the removal rate constants at the NTs electrode. Visible, for TiO 2 -Diversified modification of NTs electrodes can improve catalytic efficiency, Bi 2 o 3 The synergistic effect with AgI is obvious, which makes the separation of photogenerated charges easier.

Embodiment 2

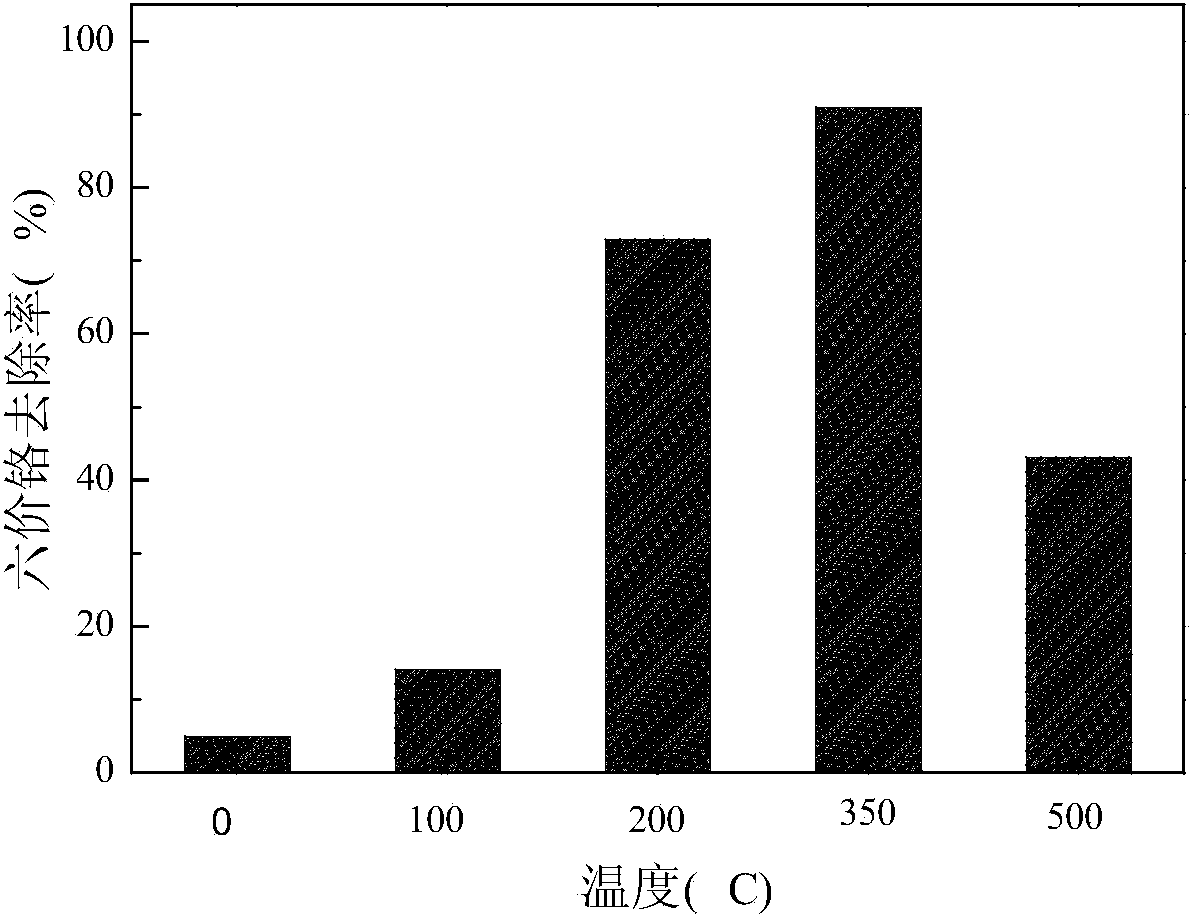

[0049] Study on Calcination Temperature Treatment vs Bi 2 o 3 / AgI / TiO 2 -The effect of photocatalytic degradation of Cr(VI) by NTs under visible light (λ﹥420nm), at pH 3, Cr(VI) concentration is 8×10 -5 Under the reaction conditions of mol / L, the concentration of Cr(VI) in each reactor with photocatalysts calcined at 0°C, 100°C, 200°C, 350°C, and 500°C was calculated respectively when the reaction reached 70 minutes. Determination.

[0050] From figure 2 Compared with no calcination treatment, the calcination treatment effectively increased the Bi 2 o 3 / AgI / TiO 2 - the photocatalytic performance of NTs, and when the calcination temperature is 350 °C, the Bi 2 o 3 / AgI / TiO 2 The removal rate of -NTs to Cr(VI) reaches the maximum and the effect is the best.

Embodiment 3

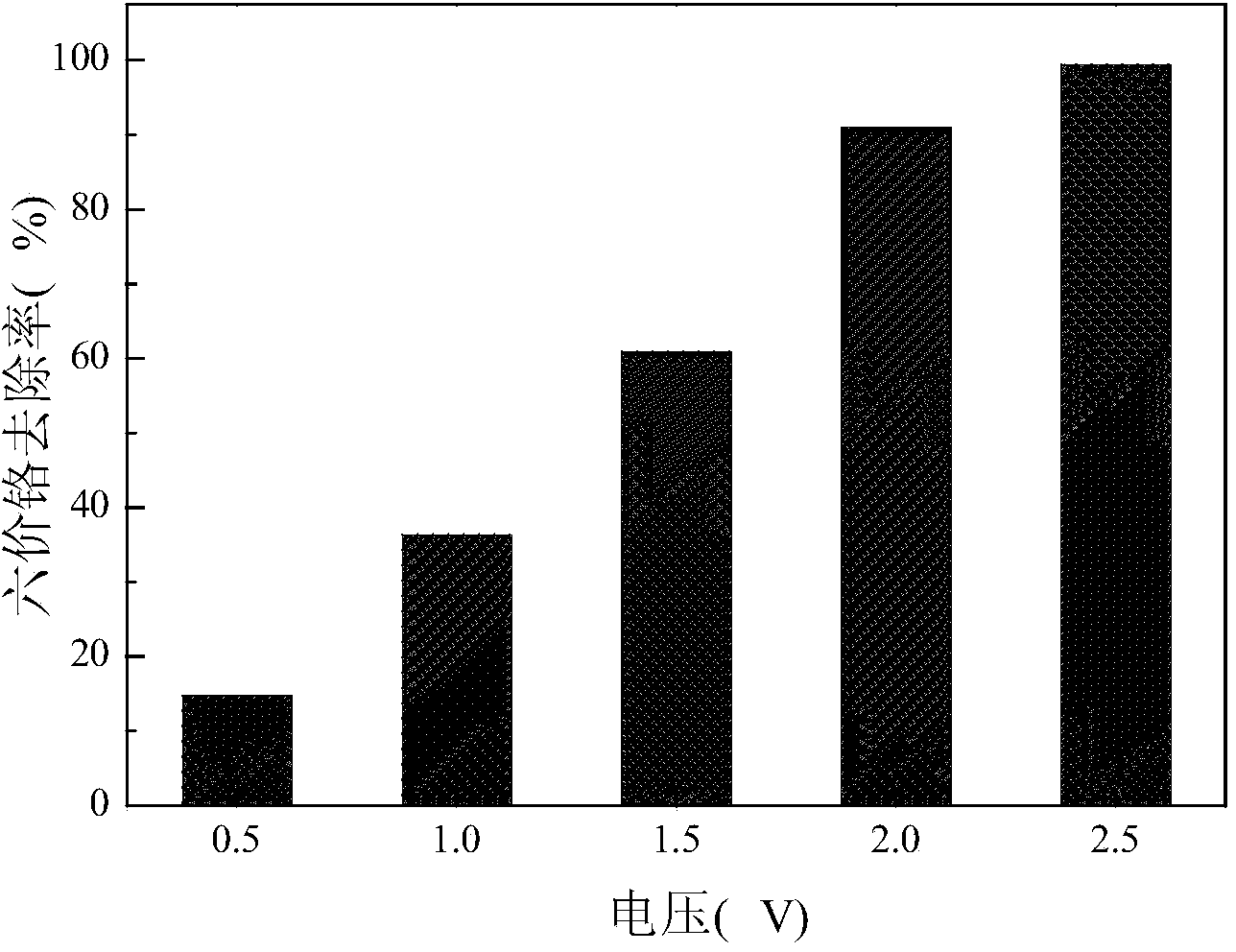

[0052] To study the effect of different applied bias voltages on Bi 2 o 3 / AgI / TiO 2 -Influence of photocatalytic reduction of Cr(VI) by NTs-350℃ under visible light (λ>420nm), at pH 3, Cr(VI) concentration is 8×10 -5 Under the reaction conditions of mol / L, the applied bias voltages of each reactor were 0.5V, 1V, 1.5V, 2V and 2.5V, respectively. The concentration of Cr(VI) in each reactor was measured when the reaction was carried out to 70min.

[0053] From image 3 It can be seen that the concentration of Cr(VI) decreases with the increase of the applied bias voltage. It can be seen that the applied bias voltage is one of the important factors affecting the photocatalytic efficiency, and it can be known from reasonable speculation that within a certain range, with the The increase of Cr(VI) removal rate showed an upward trend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com