AO/SBR system and process for enhanced nitrogen removal

A denitrification and process technology, which is applied in the AO/SBR system and process field of enhanced denitrification treatment, can solve the problems of difficult to guarantee the removal effect of total nitrogen and high idle rate, and achieve remarkable denitrification effect, less sludge discharge, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

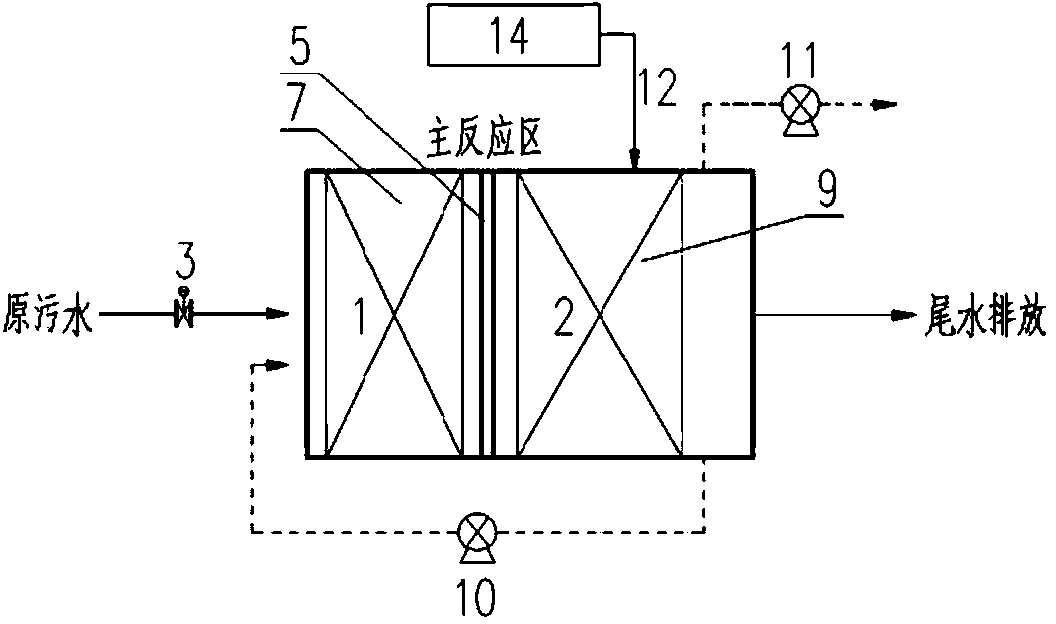

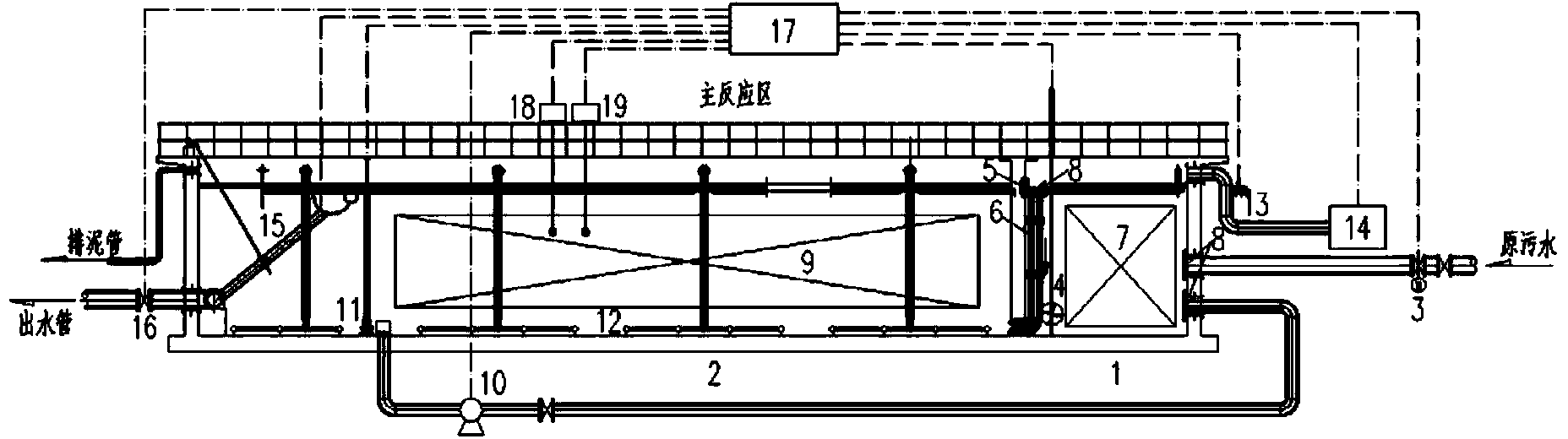

[0028] Process device of the present invention such as figure 2 Shown: including the main reaction zone, i.e. anoxic zone 1 and aerobic zone 2, inlet valve 3 for introducing raw sewage into anoxic zone 1, submersible mixer 4 in anoxic zone 1, water collection channel 5, and diversion pipe 6. Anoxic filling area 7, grid 8, aerobic filling area in aerobic area 2 9, sludge return pump (frequency conversion) for returning mixed sludge in aerobic area 2 to anoxic area 1 10. Sludge pump 11 for discharging excess sludge in aerobic zone 2, aeration pipe 12 at the bottom of aerobic zone 2, electric valve (pneumatic) 13 connected to aeration pipe 12, air compressor 14, decanting water Device 15, drain valve 16, automatic control system 17, dissolved oxygen detector 18, sludge concentration detector 19. Connected with the automatic control system 17 are water inlet pump 3, submersible mixer 4, sludge return pump 10, sludge discharge pump 11, electric valve 13, air compressor 14, decant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com