A tire casting gypsum powder containing sulfonated melamine formaldehyde resin water reducing agent and its preparation method

A technology of sulfonated melamine and formaldehyde resin, which is applied in the field of tire casting, can solve the problems of reduced water reducing rate of resin water reducer, poor fluidity and dispersion, and unstable resin performance, etc., and achieves improved sulfonation rate, good dispersibility, The effect of molecular weight stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

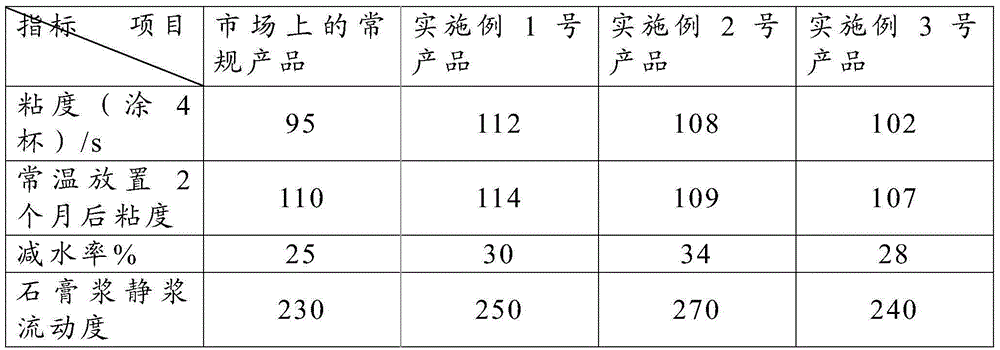

Embodiment 1

[0014] The sulfonated melamine formaldehyde resin water reducer comprises the following raw materials: melamine, liquid formaldehyde and water, wherein the weight ratio of melamine, liquid formaldehyde and water is 10:25:7.

[0015] The preparation of the sulfonated melamine-formaldehyde resin water-reducer comprises the following steps: first mixing melamine, liquid formaldehyde and water at a weight ratio of 10:25:7 to obtain a mixture, and then adjusting the pH value to 9.0 with sodium hydroxide solution , heat up to 40°C, keep warm and react for 60 minutes; add sodium metabisulfite after reacting for 60 minutes, wherein the weight ratio of sodium metabisulfite to the mixture is 1:4, sodium metabisulfite must be added slowly, and the time is controlled within 10 minutes. Use liquid caustic soda to adjust the pH value to 11, heat preservation and sulfonation reaction at 85°C for 90 minutes and then start to cool down; when the temperature drops to 50°C, add hydrochloric acid ...

Embodiment 2

[0017] The sulfonated melamine formaldehyde resin water reducer comprises the following raw materials: melamine, liquid formaldehyde and water, wherein the weight ratio of melamine, liquid formaldehyde and water is 20:52:15.

[0018] The preparation of the sulfonated melamine formaldehyde resin water reducer comprises the following steps: firstly mix melamine, liquid formaldehyde and water at a weight ratio of 20:52:15 to obtain a mixture, then adjust the pH value to 9.5 with sodium hydroxide solution , heat up to 45°C, heat preservation reaction for 60 minutes; add sodium metabisulfite after 60 minutes of reaction, wherein the weight ratio of sodium metabisulfite to the mixture is 1:4, adjust the pH value to 11 with liquid caustic soda, and keep warm at 88°C After 90 minutes of sulfonation reaction, start to cool down; when the temperature drops to 50°C, add hydrochloric acid to adjust the pH value to 4; after 30 minutes, add liquid caustic soda to adjust the pH value to 9; th...

Embodiment 3

[0020] The sulfonated melamine formaldehyde resin water reducer comprises the following raw materials: melamine, liquid formaldehyde and water, wherein the weight ratio of melamine, liquid formaldehyde and water is 15:35:9.

[0021] The preparation of the sulfonated melamine-formaldehyde resin water-reducer comprises the following steps: first mixing melamine, liquid formaldehyde and water at a weight ratio of 15:35:9 to obtain a mixture, and then adjusting the pH value to 10.0 with sodium hydroxide solution , heat up to 50°C, heat preservation reaction for 60 minutes; add sodium metabisulfite after 60 minutes of reaction, wherein the weight ratio of sodium metabisulfite to the mixture is 1:4, adjust the pH value to 11 with liquid caustic soda, and keep warm at 90°C After 90 minutes of sulfonation reaction, start to cool down; when the temperature drops to 50°C, add hydrochloric acid to adjust the pH value to 4; after 30 minutes, add liquid caustic soda to adjust the pH value t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com