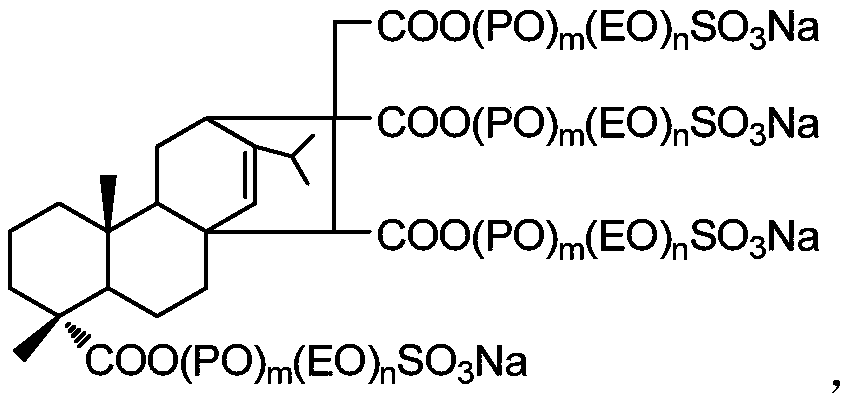

A comb-type multi-hydrophilic chain rosin block polyether sulfonate and its preparation method

A technology of polyether sulfonate and block polyether, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve problems such as deep color, low esterification rate, and low sulfonation degree of products, and achieve color Shallow, high sulfonation rate, good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the comb-shaped multi-hydrophilic chain rosin block polyether sulfonate includes the following steps:

[0036] 1) Synthesis of aconitic acid-modified rosin: melt the rosin, add aconitic acid, and fully react to obtain aconitic acid-modified rosin;

[0037] 2) Synthesis of rosin block polyether: mix aconitic acid-modified rosin and catalyst, add propylene oxide, fully react and age, then add ethylene oxide, fully react and age to obtain rosin block polyether ;

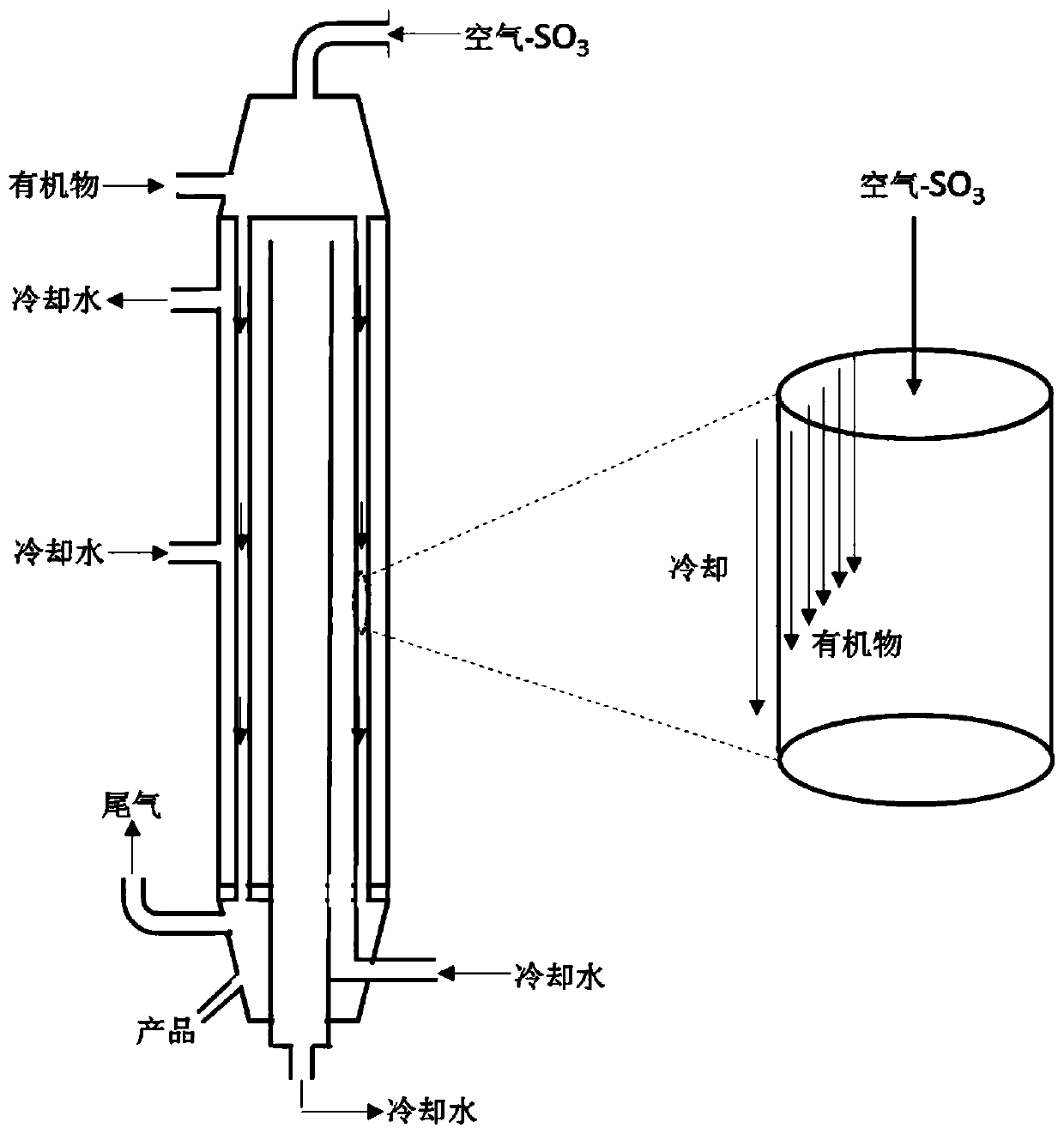

[0038] 3) Synthesis of comb-type multi-hydrophilic chain rosin block polyether sulfonate: Disperse the rosin block polyether with a solvent, and then pass it through the falling film sulfonation device from the top to flow down along the inner wall, while passing from the top Into SO 3 The mixed gas is fully reacted, aged, removed the solvent, and adjusted the pH value to obtain a comb-shaped polyether sulfonate with multiple hydrophilic chain rosin blocks.

[0039] Preferably, the molar ratio ...

Embodiment 1

[0052] A comb-shaped multi-hydrophilic chain rosin block polyether sulfonate, and its preparation method is as follows:

[0053] 1) Synthesis of aconitic acid-modified rosin: Add crushed rosin (50g, 0.17mol) into a 250mL three-necked flask, heat to 120~130℃ to melt, and then slowly add aconitic acid (28.8g, 0.17) under stirring. mol), and then react at 180~200℃ for 2h to obtain aconitic acid modified rosin;

[0054] 2) Synthesis of rosin block polyether: Add aconitic acid rosin (70g, 0.15mol) into a 500mL stainless steel reactor, stir and heat to 120℃ to melt, add potassium hydroxide (2.7g, 0.05mol), vacuum 0.5 h Remove trace water and low boiling point substances, and then use N 2 Replace the residual air in the reactor, control the reaction temperature at 155~165℃, pressure 0.3~0.4MPa, continuously and stably add propylene oxide (885g, 15mol, 100eq) dropwise, aging and absorb to negative pressure, and then under 0.3~0.4MPa, Continuously and stably add ethylene oxide (660g, 15mol...

Embodiment 2

[0057] A comb-shaped multi-hydrophilic chain rosin block polyether sulfonate, and its preparation method is as follows:

[0058] 1) Synthesis of aconitic acid-modified rosin: In a 250mL three-necked flask, add crushed rosin (50g, 0.17mol), heat to 120~130℃ to melt, then slowly add aconitic acid (57.6g, 0.34mol), then react at 180~200℃ for 3h to obtain aconitic acid modified rosin;

[0059] 2) Synthesis of rosin block polyether: add aconitic acid rosin (70g, 0.15mol) into a 500mL stainless steel reactor, stir and heat to 120℃ to melt, add potassium hydroxide (0.6g, 0.01mol) catalyst, and vacuum 0.5h to remove trace water and low boiling point substances, then use N 2 Replace the residual air in the reactor, control the reaction temperature at 155~165℃, pressure 0.3~0.4MPa, continuously and stably add propylene oxide (708g, 12mol, 80eq) dropwise, aging and absorb to negative pressure, and then under 0.3~0.4MPa, Continuously and stably add ethylene oxide (1056g, 24mol, 160eq), aging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com