A resource disposal method of kraft wood pulp black liquor

A technology of sulfate method and disposal method, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as waste of lignin resources, save concentration costs, and improve sulfonation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

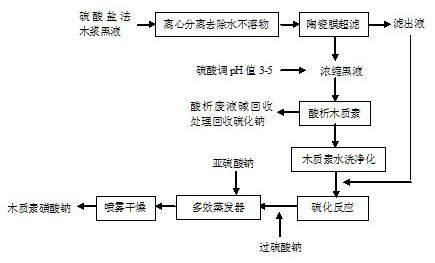

Image

Examples

Embodiment 1

[0014] The kraft pulping black liquor with a solid content of 10%: (1), add 20kg of cationic polyacrylamide aqueous solution with a mass fraction of 0.1% in every 1000kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; (2 ), at a temperature of 75°C, use a ceramic ultrafiltration membrane with a filter aperture of 10 nm to filter and concentrate the pulping black liquor to a solid content of 20%, and the filtrate is collected for use. (3) Adjust the pH value of the concentrated black liquor to 3 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 90 ° C for 1 h; ( 5), adding sodium persulfate, evaporating and concentrating in a multi-effect evaporator, adding sodium sulfite after evapo...

Embodiment 2

[0016] The kraft pulping black liquor with a solid content of 15%: (1), add 30 kg of anionic polyacrylamide aqueous solution with a mass fraction of 0.2% in every 1000 kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; (2 ), at a temperature of 85°C, use a ceramic ultrafiltration membrane with a filter aperture of 10 nm to filter and concentrate the pulping black liquor to a solid content of 30%, and the filtrate is collected for use. (3) Adjust the pH value of the concentrated black liquor to 4 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 95 ° C for 1 h; ( 5), adding sodium persulfate, evaporating and concentrating in a multi-effect evaporator, adding sodium sulfite after evap...

Embodiment 3

[0018] The kraft pulping black liquor with a solid content of 20%: (1), add 40 kg of cationic polyacrylamide aqueous solution with a mass fraction of 0.2% in every 1000 kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; (2 ), at a temperature of 90°C, use a ceramic ultrafiltration membrane with a filter pore size of 20 nm to filter and concentrate the pulping black liquor to a solid content of 30%, and the filtrate is collected for use. (3) Adjust the pH value of the concentrated black liquor to 5 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 98 ° C for 1 h; ( 5), adding sodium persulfate, evaporating and concentrating in a multi-effect evaporator, adding sodium sulfite after ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com