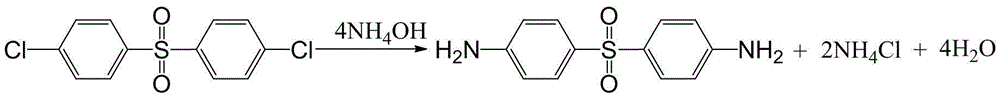

Method for preparing 4,4'-diaminodiphenyl sulfone

A technology of diaminodiphenyl sulfone and dichlorodiphenyl sulfone, which is applied in 4 fields, can solve the problems of potential safety hazards, long reaction time, and long operation time, and achieve the goals of reduced equipment investment, increased reaction yield, and safe reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The molten 4,4'-dichlorodiphenyl sulfone is injected into the pipeline reactor through a high-pressure pump at a flow rate of 140 grams / hour, while the mixture of ammoniacal liquor and cuprous chloride with a mass fraction of 25% is injected at a flow rate of 800 grams / hour. The flow rate (the flow rate of cuprous chloride is 5.6 g / hour) is also injected into the pipeline reactor through the high-pressure pump, and the continuous ammonolysis reaction is carried out at the pressure of 14Mpa and the temperature of 220°C. The residence time of the reaction material in the high-pressure pipeline is 20 Minutes; after the product is decompressed and discharged through the pressure reducing valve, the product is analyzed by liquid chromatography, and the ammonolysis product contains 0.1% of 4,4'-dichlorodiphenyl sulfone, and the discharge is sent to the recovery device, and the excess ammonia is distilled out, and the separation is obtained Crude 4,4'-diaminodiphenylsulfone; th...

Embodiment 2

[0026] The molten 4,4'-dichlorodiphenyl sulfone is injected into the pipeline reactor through a high-pressure pump at a flow rate of 140 grams / hour, while the mixture of ammoniacal liquor and cuprous chloride with a mass fraction of 20% is injected at a flow rate of 800 grams / hour. The flow rate (wherein the flow rate of cuprous chloride is 4.2 g / hour) is also injected into the pipeline reactor through the high-pressure pump, and the continuous ammonolysis reaction is carried out at a pressure of 13Mpa and a temperature of 235°C. The residence time of the reaction material in the high-pressure pipeline is 25 minutes; after the product was decompressed and discharged by the pressure reducing valve, the product was analyzed by liquid chromatography, and the ammonolysis product contained 0.08% of 4,4'-dichlorodiphenyl sulfone, and the discharge was sent to a recovery device to distill off excess ammonia and separate The crude product of 4,4'-diaminodiphenylsulfone was obtained; th...

Embodiment 3

[0028] The molten 4,4'-dichlorodiphenyl sulfone is injected into the pipeline reactor through a high-pressure pump at a flow rate of 140 grams / hour, while the mixture of ammoniacal liquor and cuprous chloride with a mass fraction of 30% is injected at a flow rate of 750 grams / hour. The flow rate (the flow rate of cuprous chloride is 1.4 g / hour) is also pumped into the pipeline reactor through the high-pressure pump, and the continuous ammonolysis reaction is carried out at a pressure of 9.5Mpa and a temperature of 250°C. The residence time of the reaction material in the high-pressure pipeline is It was 35 minutes; the product was analyzed by liquid chromatography after being decompressed and discharged by a pressure reducing valve, and the ammonolysis product contained 0.08% of 4,4'-dichlorodiphenyl sulfone, and the discharged material was sent to a recovery device to distill out excess ammonia. The crude product of 4,4'-diaminodiphenylsulfone was separated; the crude product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com